- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding work

Results for

Welding work - Import export

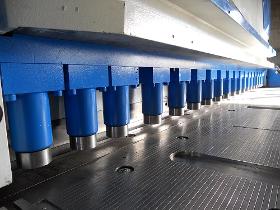

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

METAL IN LTD

Bulgaria

We offer MIG-MAG and WIG welding with maximum power of electricity 400 A. Our welding machines are KEMPPI and MILLER. We make welding of steel details, tube constructions with length till 6 meters and weight till 3 tones. We also offer spot welding and robotic welding (Fanuc) at details with length till 3 meters and width till 1.5 meters, by one or by two sides. We weld ferrous metals, stainless steel and aluminum. After welding we make cleaning of welding and painting (powder and wet).

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Rolling stock, integrated manufacturing and testing equipment, the mobility of our trade specialists are just some of the key assets we deploy to comprehensively manage your requirements, whatever your needs or the time of year. At the same time, we also perform maintenance operations on your equipment at your premises: safety compliance, refurbishment and repair, welding, metal work, electrical and mechanical maintenance, assembly and retrofitting. Our qualified employees are at your disposal and are fully accustomed to working on site with customers, whether independently or with teams working in other trades. Our teams have all the necessary clearances and qualifications to provide you with quality facilities, while working in compliance with safety regulations and your internal procedures.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Straightening press CDN400 with 3100x3000mm table and 1000mm stroke helps us finish our work with great precision.

Request for a quote

OREMUS S.R.O.

Czech Rep.

In our team, certified welders with more than 20 years of experience are working, using precision working plates for weldments up to 4000x6000mm and even more. Our welding shop is equipped with cranes 3,5t / 5t / 20t

Request for a quote

OREMUS S.R.O.

Czech Rep.

It is not so common, but it greatly increases the efficiency in our welding shop

Request for a quote

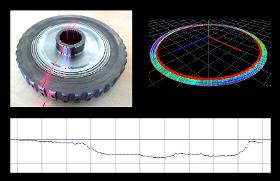

QUELLTECH GMBH

Germany

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

IGUS® GMBH

Germany

Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E4/4 "Mounted on the side" - Travel distances over 200 m "Mounted on the side" - Travel distances over 200 m Extensive unsupported lengths for "side-mounted" applications Roller E-Chain® links available (with roller chain) Max. travel distance: 200 - 800 m High torsional stability Manifold interior separation potentials Large accessory kits Typical industrial sectors and applications RTG, quayside cranes, many other types of cranes Composting plants Gypsum, concrete, chemical and mineral plants, as well as agricultural plants Machine tools: unsupported, side-mounted applications Construction machinery ESD applications Heavy machinery Steel works Shipyards Welding plants ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels

Request for a quote

NOVELTY STEEL

Turkey

Carbon Steel and Stainless Steel Robot Laser Welding Part Manufacturing

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures various steel frames for various structures and machinery. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame or structure. The fabrication process of steel products can be categorized into 5 steps primarily based on the sequence of the task. These are: Steel Detailing Steel Profiling Cutting Bending Rolling Drilling Welding Surface Preparation and Painting Packagin At Novelty Steel, we usually use readily available steel sections that are purchased from the steel mills, together with complementary material such as protective paints and fasteners from other specialist suppliers. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is a contract fabricator of bespoke structural steel works comprising metal cutting, bending, machining, welding and painting. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HFP BANDSTAHL GMBH & CO KG

Germany

Our tasks also include joint process optimization with our customers in order to enable more efficient production and thus a reduction in set-up and downtimes. Our spooling systems are a good example of this type of cooperation and continuous further development. We connect the strips using state-of-the-art welding technology and rewind them oscillating on a variety of spools Strip widths from 1.5 mm up to 60 mm Extension of the strip length to more than 200,000 meters in one strip depending on the material Individual laying widths from 100 to 400 mm Special decoiling racks with decoiling widths of 800 mm and maximum decoiling weights of 2,500 kg

Request for a quote

CMPLAST

Poland

Our company's offer includes welding of steel structures made of stainless steel and carbon steel. Welding is carried out using the method MIG / MAG creation of an electric arc between the head and the material. It is covered with shields of mechanical gases such as, for example, neutral (argon) or chemically active (carbon dioxide); TIG welding using a tungsten electrode and a shield of noble (inert) gas, most often argon. We combine elements of standard size as well as largesize items We provide welds with the highest usable parameters, but after the welding process, the combined elements are additionally grinded and we remove any sharp edges or endings

Request for a quote

NOVELTY STEEL

Turkey

Aluminium fabrication plays an essential role in metal fabrications for a variety of industries. The metal’s light weight, corrosion resistance, and ductility make it ideal for many applications from automotive parts to medical devices. Aluminium isn’t always easy to work with. The appropriate practices and equipment is necessary if you want to avoid welding defects or damage. The choice of alloy, welding gas and joining method can all have a significant effect on the quality of finished products. Due to aluminium’s unique characteristics, aluminium fabrication differs from the other metals. Low weight density of aluminium is common knowledge which brings various advantages and disadvantages in the fabrication. Although aluminium has a weaker mechanical properties, it still possesses higher strength to weight ratio compared to stainless steel and carbon steel in various applications.

Request for a quote

RUDOLF UHLEN GMBH

Germany

• The leather mask is suitable for use in welding work, particulary in forced positions • The mask is made of soft cowhide • The welding glasses can be lifted up if needed • The glass holding frame is designed for removable lenses with 50mm diameter • A spring-loaded catch makes it easy to change the lenses • Also available as a version with additional neck protection

Request for a quote

KASAG SWISS AG

Switzerland

KASAG undertakes cutting, forming and welding works for manufacturing simple and complex welding constructions of up to a weight of 13 t in stainless steel and aluminium. Our specialists have been certified according to ISO 3834-2 in all required welding processes MIG, MAG, TIG, plasma and orbital.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connectors – the flexible alternative to welded connections The clampable tube connectors from RK Rose+Krieger are a cost-efficient solution for the positive and ready detachable connection of a diverse variety of systems – without the need for drilling and welding. Depending on the field of application and the expected load, RK Rose+Krieger offers tube connectors made of plastic (Light Clamps), aluminium (Solid Clamps) or stainless steel (Robust Clamps). The Solid Clamps tube connector system also includes the RK monitor mounting for the fixation and ergonomic adjustment of monitors and touch screens used in industrial applications. Say goodbye to welding – that could be the motto of the clampable RK tube connectors The simple assembly technology of the clamping elements eliminates the need for time-consuming and cost-intensive drilling and welding work.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

DVK-HD® high pressure pipe couplings are perfect for a quick and well-priced mounting for pressure conveyors. They have the following characteristics: for outer pipe diameter from 60.3 to 206.0 mm length: 100, 150, 200 mm or longer metal casing made of aluminium AlMgSi 0.5 F22 massive aluminium clamps (double secured) screws M12 with massive threaded bars pressure-resistant up to maximum of 12 bar (see table) vacuum-resistant up to maximum of 0.8 bar (see table) circular version, therefore very easy to mount white EPDM gasket or nitrile gasket, temperature-resistant and food-safe optionally available with silicone gasket (-60°C to +200°C) Mounting these pipe couplings is safe and hazard-free because no welding works are necessary. They also can easily be dismantled – connecting pieces and pipes can be reused.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The self supporting, lightweight diaphragm construction made of stainless steel – with high mechanical strength and resistance to ageing – enables tanks with diameters of up to 50 m to be spanned. The stainless steel not only provides support but also seals off the tank and can withstand snow loads and high winds. The Lipp stainless steel diaphragm cover is corrosion resistant, gas and vapour diffusion tight and provides reliable protection against UV radiation and mechanical damage. The lightweight design of the diaphragm makes it ideal for covering volatile and explosive substances and prevents components from flying around in the event of an explosion. Prefabrication of the diaphragm at the factory eliminates the need for welding work to be carried out at the construction site.

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfuction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment Interface for automatic components: optional Stud counter

Request for a quoteResults for

Welding work - Import exportNumber of results

150 ProductsCountries

- Germany (45)

- Turkey (29)

- Italy (17)

- Poland (13)

- Russia (6)

- Lithuania (5)

- Portugal (4)

- Ukraine (4)

- Austria (3)

- China (3)

- Czech Rep. (3)

- Serbia (3)

- Taiwan R.O.C. (3)

- France (2)

- United States (2)

- Bulgaria (1)

- Greece (1)

- Ireland (1)

- Latvia (1)

- Slovenia (1)

- Switzerland (1)

- Thailand (1)

- United Kingdom (1)

Company type

Category

- Welding work - steels and metal (89)

- Autogenous welding machines (7)

- Welding, soldering and brazing - equipment and supplies (6)

- Laser - cutting and welding machines (5)

- Metallurgy - machinery and installations (4)

- Steels and metals - welding and brazing (3)

- Milling - steels and metals (3)

- Metal structural work (2)

- Electron beam welding - equipment (2)

- Galvanization - steels and metals (2)

- Overalls and aprons (2)

- Steel, structural (2)

- Aluminium alloys (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Cold rolled steel strips (1)

- Coupling, pneumatic (1)

- Disposable medical and surgical articles (1)

- Furniture - restaurants, bars and cafés (1)

- Heat treatment of steels and metals (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)