- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- micro-drilling

Results for

Micro-drilling - Import export

STEEC

France

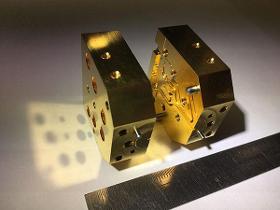

At its 4 CN machining centres STEEC drills and taps holes of very small dimensions down to diameters of a few tenths of microns. STEEC carries out micro-drilling work on conventional machining centres. STEEC is able to machine parts in small and medium series or units parts that may have several tens of thousands of holes per parts. The company has acquired know-how and expertise recognized by multiple audits by major contractors in this technology. These audits have also led to special prestigious certifications. This technical solution may be applied in all industrial sectors, from aerospace to the medical sector, also including research or the automotive industry.

Request for a quote

STEEC

France

This modern machining technology offers a host of advantages over more conventional processes. STEEC makes available to its customers its know-how in micro drilling by spark erosion. The principle of this machining process is the same as for wire spark erosion, except that the tool used for cutting is no longer a wire but an electrode shaped according to the precision machining require. The part and the tool (electrode) are not therefore in contact with each other, in fact it is an electric arc formed between the electrode and the part that will machine the latter. This is also called sparking. The part must be necessarily be conducting to be able to be machined by this method and it is prerequisite for using this method. This absence of contact between the tool and the part makes it possible to machine very hard materials such as titanium for example.

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quote

STEEC

France

The nuclear sector is one which requires extreme precision as well as the ultimate discipline. This also includes machining of course. STEEC provides the players in this sector high-tech subcontracting solutions in micro-drilling or conventional micro-machining and laser micro-cutting. Major French and European companies in the nuclear sector put their trust in STEEC for the manufacture of micromechanical parts.

Request for a quote

STEEC

France

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LEICA MICROSYSTEMS

Germany

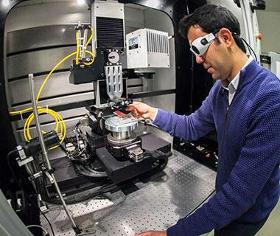

Visually inspect and chemically analyze in a single work step with your DM6 M LIBS materials analysis solution. The integrated laser spectroscopy function delivers the chemical composition of the microstructure that you see in the microscope image – within a second. Speed up your workflow. The LIBS module turns a Leica optical microscope into a 1-step solution that combines visual inspection and chemical analysis right at your workspace. Determine the composition of what you have visually identified within seconds. Use LIBS to perform advanced material analysis 90% faster compared to inspection with SEM/EDS. Surface contamination or coatings can also be easily removed. Chemical mapping and micro-drilling are further analytical steps.

Request for a quoteResults for

Micro-drilling - Import exportNumber of results

7 ProductsCountries

Company type