- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- motor pulleys

Results for

Motor pulleys - Import export

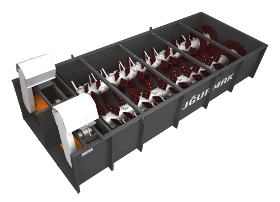

UGUR MAKINA CRUSHING & SCREENING

Turkey

They are produced with double shafts. On the shaft, there are detachable fixed spiral leaves and washing shovels lined up with the most suitable combination. It is very easy to replace shovels and spiral leaves since they are detachable connected. These shafts are driven by motor, reducer and belt pulley system.

Request for a quote

RM2M

France

Industrial Pulley Blocks for Wire Hoists and Winches Range: We provide industrial pulley blocks specifically designed for hoists and winches. Features: Equipped with 1 to 8 pulleys Standard equipment: single hook (DIN 15401 standard). Less common option: double hook (DIN 15402 standard). Lifting Capacity: lifting loads from 500 kg to over 250 tons. Applications: for cranes, overhead bridges, etc.. Upon request,: pulley blocks with motorized rotation of hook pulley blocks with locking of hook each 90° pulley block with weighing of load

Request for a quote

METMANN

Spain

High flow industrial roof extractor for the extraction of stale air HELIX BOX MANN industrial roof extractors have an extraction capacity from 21,000 m3/ h to 39,800 m3 / h and are the perfect solution for the extraction of stale air in industrial buildings, warehouses, farms, greenhouses, etc. Main features - Air flow from 21,000 m3/h to 39,800 m3/h - External structure made of galvanized steel. - Overpressure shutter made of galvanized steel. - Propellers made of AISI 430 BA stainless steel. - High quality bearings. - IP-55 three-phase electric motor - V-belts. - Transmission pulleys made of magnesium aluminum. - Engine support with tensioner. - Roof supports. - Air inlet with protection grid. - Anti rain visor.

Request for a quote

METMANN

Spain

High flow wall fans for extraction and/or ventilation This type of fans provide significant air flows for the extraction and/or ventilation of industrial, livestock or agricultural premises. Main features - Air flow from 21,000 m3/h to 39,800 m3/h - Structure and overpressure slats in galvanized steel to avoid premature corrosion. - Propellers made of AISI 430 BA stainless steel. - High quality bearings. - IP-55 three-phase electric motor - V-belts. - Transmission pulleys made of magnesium aluminum. - Engine support with tensioner. - Side inserts for easy transport.

Request for a quote

COMERC SP. Z O.O.

Poland

Skorpion 650 EB is a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 650 mm. The drive section of Skorpion 500 EB chipper is a 90 or 110 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipper includes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COMERC SP. Z O.O.

Poland

Skorpion 350 EB is a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 350 mm. The drive section of Skorpion 350 EB chipper is a 37 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipper includes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer discharging device for residual liquid permits emptying residual liquids from reusable bottles. Bottles with large quantities of residual liquid can be fed into the machine via a bypass. Cleaning occurs during continuous material flow. In addition to turning and cleaning, differences in height can be overcome at the same time. Technical data: —Conveyor performance: up to 60,000 units/h —Overhead track: up to 10 m —Difference in height: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid —electrical control system —loading and unloading belts —water lances for cleaning support of the cleated chain

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer head space moistener permits moisting of the cap with the fluid in the container. Machine dimensions depend on the conveyor performance and the desired moisting time. Moisting occurs during continuous material flow. The machine is a space-saving solution due to the vertical moisting track. The design permits products to run through the machine without turning process, if necessary. Technical data: —Conveying performance: up to 60,000 units/h —Moisting path: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid with maintenance doors —electrical control system —loading and unloading belts

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9245-75 High quality machine suitable to sew furniture and upholstery. This machine has a 75 cm space between needle and frame. Large hook. The machine is delivered with extra heavy stand on wheels and table top (no motor). Motor Set External synchroniser SY0129 (600-29), G 60 Servomotor (optional: external synchroniser G series), i60-4-GL-220, MT0160 – 600 Watt mini motor, No Motor Set, Pulley Option for i60-4-GL-220 pneumatic presser foot lifter WF 1335, 9245, ZZ 1266, Pneumatic backtack WF 1335, 9245, Set PFL + BT WF 1335, 9245, Switch manual back tack with bracket, Operator panel C200 (OP0405)

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

LP 1768 AUT – Single needle walking foot postbed machine with thread trimmer, automatic back tack, presser foot lift, quick stroke adjustment for assembly and topstitching operations in home upholstery, car upholstery and leather. LP 1768-2 AUT – Double needle walking foot postbed machine with thread trimmer, automatic back tack, presser foot lift, quick stroke adjustment and integrated second stitch length for assembly and topstitching operations in home upholstery, car upholstery and leather. Standard needle gauge 8 mm. Products LP 1768 AUT, LP 1768-2 AUT Table Top No Table Top, Table top D 125x60x4 cm for WF 1767 Stands No Stand, Stand K (912 mm), Stand K short (667 mm) Motor Set External synchroniser SY0129 (600-29), i701ED – i70L-4-ED-220, i904ED – i90M-4-ED-220 (750 W) + synchro 600-29 for heavy duty, Mini motor pulley 65 mm., MT0175 – 750 Watt mini motor, No Motor Set, OP0102 – C300 operator panel, OP0202 – C300M operator panel

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

1. NBR shaft seals on hardened cylinder barrels Drum motors axles are usually manufactured from ST37. Commercially available seals rotate directly on the axles. The result, at some point in time, is grooves on the axle. In addition of course oil leaks. This is not the case with the FTK Förderband Technik Kilian pulley motors all drum motors are equipped with hardened and polished cylinder barrels made of stainless steel 316. 2. Oil loss is not a problem for us! Oil change after 50,000 hours of work. Today, for reasons of cost, fewer and fewer users concern themselves with plant maintenance. The maintenance of complex plants is mainly carried out by outside specialists. Simple prefabricated parts, however, are usually used till worn out. This is also the case with drum motors. We have made allowance for this behaviour. The FTK Förderband Technik Kilian drum motors only require an oil change after 50,000 hours of work. In the case of operation with 3 shifts for example

Request for a quoteResults for

Motor pulleys - Import exportNumber of results

12 ProductsCompany type