- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal plates

Results for

Metal plates - Import export

AEROLIFT INDUSTRIALS B.V.

Netherlands

Sheet metal handling and lifting steel plates with vacuum technology. Both magnetic and non-magnetic sheets are easily lifted. The suction pad is placed on the metal product, after which the vacuum is activated by a push on the button. Now you can lift, move, or even turn the sheet metal. Vacuum lifting is used during production, storage, internal transport, transhipment, and construction. Besides vacuum lifters for metal plates, we also design pipe handling equipment. All our designs are custom made to perfectly match the individual situation. Why choose lifting plates by vacuum? Vacuum offers unique advantages compared to other lifting methods to lift plates, such as chains, clamps, and magnets. Chains and clamps can be used to lift non-magnetic plates, such as aluminium, copper, and stainless steel. Compared to these lifting methods, vacuum offers distinct advantages: No damage to the plate, not even scratches No spacers or stoppers required Easy and fast handling Less manpower

Request for a quote

INTERLINEX B.V.

Netherlands

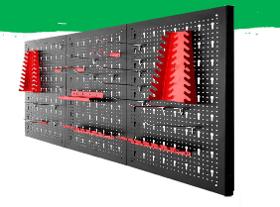

Max load; 4kg (per plate) 3x metal plates 2x key holders 2x screwdrivers 4x hammer hangers 1x drill support 16x hooks

Request for a quote

AEROLIFT INDUSTRIALS B.V.

Netherlands

Why choose lifting magnets? Or why opt for a vacuum lifter? In the article below we explain why we recommend using a vacuum lifting over magnetic lifting. Complete control Unlike a vacuum lifter, a magnet lifter is able to lift a stack of metal plates at once. However, the upper plate is safely attached, but the other plates are an overload and could come off. Creating an unsafe lifting situation. Vacuum lifting is precise, safe and offers complete control during the complete handling process. Increased lifting capacity A magnet lifter is extremely heavy due to the heavy backup system. In comparison a vacuum lifter is light as a feather. The big difference in weight results in the possibility to increase the lifting capacity (maximum lifting capacity of the crane = weight of the metal plate + weight of the lifter). If you decrease the weight of the lifter, it means you can lift heavier plates.

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

Creating an optimal bond between a metal plate and the silicone: that was the challenge Enbi Plastics was given by Océ Technologies, a major player in printing and copying equipment. They needed a new wiper assy; a part on the print head that prevents streaks on the paper. Because this part needs to be somewhat flexible, silicone needed to be added to a small, punched metal plate, to which screw thread is welded. This construction did not allow for a mechanical bond between the metal and silicone, which meant chemical bonding was the only option. Together with the client, the mould supplier, the silicone supplier and others, we did extensive research into the best way to achieve this bond. It showed that preparing the small metal plates was the key. After several tests, we discovered the optimal way to do this. A number of factors play a role: from how to clean and sand the plate to humidity, temperature and the time in between the steps of the process. Every detail counts!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Metal plates - Import exportNumber of results

4 ProductsCountries