- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- printed circuit board

Results for

Printed circuit board - Import export

ONE2ID B.V.

Netherlands

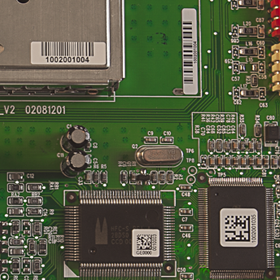

ONE2ID’s high-quality polyimide (Kapton®) labels can withstand high temperatures and are resistant to the chemicals most commonly used in the manufacturing of printed circuit boards (PCB). This type of label material is specifically designed to endure extremely high temperatures as well as aggressive chemicals. Circuit board labels can be applied either before, during or after the printed circuit board manufacturing process. A combination of strong adhesive qualities and resistance to heat and harsh chemicals protects the barcode code in order to retain its legibility for both the human eye and scanning equipment. The several layers that make up the label stay intact with the label firmly attached to the surface, even during exposure to aggressive chemical solvents. In short, polyimide labels are the perfect choice for circuit board identification.

Request for a quote

ONE2ID B.V.

Netherlands

Industrial processes place high demands on the type of labels used for identification. These include processes such as painting, powder coating, wet painting, soldering, chemical pre-treatment, KTL painting processes, autoclave processes (sterilisation) and printed circuit board (PCB) production. During these processes, barcode labels are often exposed to extremely high temperatures or aggressive industrial cleaning agents, which a simple paper label cannot withstand. ONE2ID has a wide range of heat-resistant materials that can be used up to very high temperatures.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing semi-fine (and semi-coarse) atomization having a mean droplet diameter of 50μm or more. (*3) High spray impact with thin flat spray pattern and uniform distribution. Liquid pressure type under the liquid pressures of 0.2–0.5 MPa (ca. 2 bar – 5 bar). Large turn-down ratio with stable spray angle. Spray angle of 60° or 80° *1) Measured at compressed air pressure of 0.4 MPa (ca. 4 bar) and liquid pressure of 0.5 MPa (ca. 5 bar). *2) Free passage diameter of nozzle orifice. *3) Measured by Laser Doppler Method. Applications Cleaning: Printed circuit boards, liquid crystal, liquid crystal display, steel plates [Steel making industry] Surface finish process: Precision cleaning for steel surface treatment, Roll cleaning

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Printed circuit board - Import exportNumber of results

3 ProductsCompany type