- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pad printing on stoppers

Results for

Pad printing on stoppers - Import export

LINDNER SPRÜHSYSTEME GMBH

Germany

Would you like to get your promotional items or other products printed? For over 20 years our customers can rely on the highest quality, the best consulting and the optimal quality-price ratio.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Abrasion resistance/Zirconia ceramic ring for sealed ink cup/pad printing/innovacera 1. Introduction: Round Zirconia ceramic ring is used for a Ever Bright pad printing ink cup machine, electronic control, lighting and electrical temperature control and other industries.Zirconia ceramic scraper ring is also used for thermostat,technical ceramic,temperature control. The temperature controllers,manufactured with Zirconia,have revolutionary breakthrough if compared with traditional plastic parts.They are highly improved in strength,insulation performance,heat resistant performance,especially sensitivity to temperature Innovacera is offered Yttria Tetragonal Zirconia Polycrystal(Y-TZP), there are many applications of Zirconia ceramics in the chemical and petrochemical industries. They provide economic payback in the way of reduced maintenance and down time. Zirconia ceramics is also becoming the material of choice for components in healthcare applications.

Request for a quote

PLÁSTICOS CLOSSA

Spain

In the constant search to adapt to the demands of our customers, we have included a tampon printing process in our facilities. We print our own parts or others manufactured by third parties. We use multi head technology. This allows us to be able to do in one pass, which would normally take two. And therefore, reduce costs. We process parts intended to all industry sectors.

Request for a quote

TAMPOPRINT GMBH

Germany

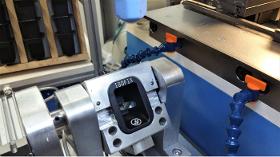

With the “Modular Automation Platform” TAMPOPRINT presents an automation-platform, whose entities can be freely put together in building block concept. The base frame, available in two sizes, offers up to 16 positions, which easily can be assembled with pad print, laser, pre-treatment as well as post-treatment and surveillance units. Outfitted with large machine doors, it enables the operator absolute open access into the interior of the pad print automation. Furthermore added is the revolutionary re-thinking of the layout of the pad print unit. To simplify registration and reduce setup-times, the cliché unit is mounted outwards facing the operator. Cliché changes and replenishing the ink is accomplished within a few seconds

Request for a quote

TAMPOPRINT GMBH

Germany

The CONTINUOUS CIRCULAR with its 360º rotary printing process convinces through its registration accuracy for an enhanced process control and herewith accompanying for a better quality and higher precision, compared to conventional pad printing solutions. The very simple operation is achieved by an easy-view and easily understandable technology, which also contributes for lower set-up costs. The CONTINUOUS CIRCULAR is both available as single-color, as well as multi-color pad printing machine. With this innovative pad printing machine, highest and brilliant print image quality is achieved, also with the application of metallic inks, e.g. Gold and Silver

Request for a quote

TAMPOPRINT GMBH

Germany

The V-DUO series features 2-color machines. Its unique functional principle allows very high performance. The V-shaped pad bridge facilitates parallel print image transfer and print image pick-up. A further benefit is the printing of both pads at one printing position, resulting in a very high register accuracy. The combination of V principle and universal control makes it possible to fulfil practically any wish. The variaty of setting options can be saved in 5 program sequences. Each pad can be independently programmed with all functions. The function ”start of production” allows actuating customer’s automations. The two cliché holders are provided with an x-y-w adjustment option. As an extension to semi-automation, we offer the V-DUO which can be set up on the rear side as an installation variant in our MODULE ONE series with various add-on components.

Request for a quote

TAMPOPRINT GMBH

Germany

For pad printing process screen printing inks (CMYK) as well as opaque pad printing inks in various ink shades are used. Today, the comprehensive range of pad printing inks enables the customer to choose a pad printing ink type exactly tailored to his requirements. The range of products includes a variety of color types and shades. Also, specially desired shades can be produced in the in-house color laboratory. TAMPOPRINT pad printing inks comply with the REACH Directive (EG) No. 1907/2006 and the RoHS Directive 2011/65/EU.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT pad printing and fully automatic laser machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts by using the pad printing process, one to multicolor, or by using the ALFALAS® laser marking process goes without saying and meets the high standards for these industrial products. Process monitoring by using the latest camera systems will secure your production. We make markings, scales and decorations possible where other processes reach their limits.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT offers a wide range of ink/doctoring cups for "hermetic" standard pad printing machines. Available are sizes with diameters of 30/40/60/90/130/140/150/210 mm in plastic, aluminum or steel with ceramic or carbide doctoring ring. Multi-color ink/doctoring cups, pressure rings and pressure ring adapters are also available. The ink/doctoring cup is used in the "hermetic" pad printing process to transfer the printing ink to the cliché in a single operation and simultaneously remove the ink (doctoring).

Request for a quote

TAMPOPRINT GMBH

Germany

For over 30 years TAMPOPRINT GmbH has been an established partner of the beverage and closure caps manufacturing sector and their suppliers. Today our high know-how distinguishes us and makes it possible to supply you with decorating and marking solutions with our rotary pad printing and laser marking technology. Our pad printing and laser automations meet highest quality requirements for the applications in multi-shift operations with high throughput speeds. As an expert for special solutions our project planning can draw on many years of experience.Our rotary pad printing automations offer highest precision in print image registration on convex, round or flat parts, one- or multi-colored. Additionally we offer with our brand ALFALAS® the laser marking ”Mark on the Fly” – bottle caps marking for competitions and promotion campaigns.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT GmbH is a well-established partner for the European brand manufacturers in the toy industry. Our pad printing and laser marking automatic machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts using the pad printing process, one to multicolor, in colorful micro printing are a matter of course and meet the high standards of modern industrial products. Process monitoring using camera systems will secure the quality of your production. Whether smallest toy parts, difficult shape formings or large-sized toy parts, smallest eyes or colorful areas, TAMPOPRINT has the suitable automation.

Request for a quote

TAMPOPRINT GMBH

Germany

High requirements are the core competence of the RAPID machine series. At home in the construction of automated systems with very high performance requirements. An energy-efficient electromechanical drive with extremely quiet running for precision designed printing motifs will guarantee your additional benefit. The User-friendly touch panel offers a number of setting options and makes it possible to coordinate the machine exactly to your customer-specific task. The RAPID series is available with useful, practical and additional extensions for individual configurations.

Request for a quote

TAMPOPRINT GMBH

Germany

The electro-pneumatic drive of the doctoring unit offers high speeds and the pneumatic pad stroke movement maximum flexibility. Superb accessibility on all four sides is guaranteed. Print image transfer takes place at only one workpiece position. Processes such as ink pick-up, ink transfer and ink residue pick-up system take place synchronously. A result is the high performance. Ink residue pick-up system and integrated VIPA S7 PLC control are a standard option. Program enhancement possible at any time. Up to 10 program variants per printing station can be stored. Memory cards for additional jobs can be integrated in the external operator panel.

Request for a quote

TAMPOPRINT GMBH

Germany

The universal HERMETIC series offers a multitude of application possibilities due to its various features. In particular, the electromechanical drive with its very quiet running has predestined the HERMETIC series for integration into automated systems. The ink residue pick-up system (option) can be integrated into the machine housing, allowing the machine to be used in confined spaces. Exclusive to TAMPOPRINT is the adjustable pad stroke onto the workpiece in combination with an electromechanical machine drive. The variable contact pressure of the ink/doctoring cup offers optimised service lifetimes for the printing clichés used and the best results for doctoring. In addition to all the above advantages, the HERMETIC 150 offers a max. print image size of Ø 140 mm. An (optional) ink residue pick-up system can be fitted either on the right or left of the machine.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT GmbH is a well-established partner for the medical industry. We make markings, scales and decorations possible where other processes reach their limits. Starting with the project planning, the de-risking via validation process, URS, FMEA, IQ and OQ, via FAT and SAT to the production support. Our pad printing and laser fully automatic machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts by using the pad printing process, one to multicolor, or by using the ALFALAS® laser marking process goes without saying and meets the high standards for medical products. Process monitoring by using the latest camera systems as well as their validation will secure your production and the health of the patients.

Request for a quote

TAMPOPRINT GMBH

Germany

Without the pad printing process, the production of everyday objects such as decorated light alloy wheels, or even vital items such as insulin pens would not be easily possible. In doing so, TAMPOPRINT develops and works on process printing solutions across industry boundaries. Thus, there is no such thing as the typical TAMPOPRINT customer or the typical application. Rather, the fields of application are characterized by their diversity, their complexity and their individual characteristics. They range from the simpler printing of toys such as model trains, to the labeling of household appliances and beverage bottles, to highly complex processes such as the micrometer-accurate labeling of medical products, e.g. insulin pens and laboratory tubes. Even the particularly challenging direct application of active pharmaceutical ingredients onto a carrier material, such as in nicotine patches, can be implemented thanks to the TAMPOPRINT solutions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAMPOPRINT GMBH

Germany

The ergonomic guiding idea for the MODULE ONE series was to develop a machine that is easy to operate and whose processes are immediately visually apparent. In addition, it should be simple, safe, and user-friendly. The MODULE ONE series consists of 4 different models: MODULE ONE M and MODULE ONE S are semi-automated machines. MODULE ONE XS and MODULE ONE XXS are manual workstation solutions. Pad printing machines of the HERMETIC, SEALED INK CUP and V-DUO series are available for placement of the MODULE ONE series. With the MODULE ONE series, up to 1200 parts/h can be printed with up to two or three colors in high precision. With a print image in up to three colors, the series is suitable for decorating and labeling a wide variety of printed goods such as toys, figures, model vehicles, etc., but also for marking technical devices and components.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT offers a comprehensive range of tampon printing accessories. From accessories for tampon printing machines such as printing pads and ink/doctoring pots to practical devices for everyday tampon printing. True to the motto "Everything from a single source".

Request for a quote

TAMPOPRINT GMBH

Germany

The RTI Compact II E is a single-color rotary pad printing machine. Designed as a manual workstation, it is primarily used to print circular cylindrical or flat parts. The basic body consists of an ergonomically designed base frame with protective enclosure and light curtain. The RTI COMPACT II E is consistently designed for ease of maintenance and short changeover times. User-friendliness and easy accessibility of the tampon roller characterize the machine. In addition, the RTI COMPACT II E is equipped with a residual ink pickup for automatic pad cleaning.

Request for a quote

TAMPOPRINT GMBH

Germany

With the SEALED INK CUP series you will receive a modern and technologically high-quality electropneumatic pad printing machine. The ideal starter model for stand-alone use. The SEALED INK CUP can be connected to transfer systems or components of your automated system. Thanks to a 37-pole automation interface (standard equipment), it is now prepared for the design enhancement with optional features. Its control is easy to operate. The SEALED INK CUP series shows an internationally convincing price-performance ratio ”Made in Germany”.

Request for a quote

TAMPOPRINT GMBH

Germany

There was a need for coming up with a new pad printing machine, the basis of which opens up new target markets for us both technologically and in terms of applications. The result: the development of the SPEED 40-2 pad printing machine. Its output: as many as 9,000 cycles/h in continuous run. The production quantity is max. 18,000/h printed parts (single color with a printed image size of Ø 37 mm). Very high true-to-register printing, precision contours and photo and line images. The SPEED is a built-in execution, suitable for any kind of clocked, linear or rotary transfer systems. Thanks to its integrable misprint device there is no stopping of the machine in the absence of a workpiece. The power costs are low in comparison to the cycle number (part output). The SPEED 40-2 is a fast shortstroke machine of a new series of pad printing machines.

Request for a quote

TAMPOPRINT GMBH

Germany

In our cliché factory, we have been working on new cliché materials and developing suitable imaging processes for decades. This means that today we can produce the optimum cliché for every application. Our years of practice enable us to respond to the special features of pad printing and use them to achieve the best result. Whether single or multi-color - we will be happy to advise you on the selection and ordering of your suitable tampon printing cliché for self-imaging or ready-to-print. In our in-house prepress department, our experts create finished print images from your artwork and ideas. With your approval, you will receive a print-ready result in the shortest possible time. Our TAMPOPRINT cliché range is suitable for all standard printing applications and tampon printing systems.

Request for a quote

TAMPOPRINT GMBH

Germany

TSM – universal transverse doctor blade kit for print motifs up to a length of 520 or 650 mm and a print image up to 80 or 130 mm wide. The special feature here is that it is able to handle extremely large or very long print images on one and the same printing unit in just one printing pass. It is ideally suited for long printing parts that require a lot of print. Versions with servomechanical drive are characterized by a very high number of cycles and a very high force of pressure. Energy-efficient cinematics in doctor or pad movement and a resource-saving machine frame construction round off the successful machine concept.

Request for a quote

TAMPOPRINT GMBH

Germany

Die ROTOPRINT ist zur Verschlusskappenbedruckung die wirtschaftlichste Lösung mit höchsten Qualitätsmerkmalen bei maximaler Leistung. The ROTOPRINT can be equipped for printed images with between one and three colors. Depending on equipment, the concept enables an output of max. 3000 printed bottle caps/min. (28 mm diameter). With all variants, products are supplied using the tried and tested ascending conveyor. This prevents unnecessary machine stops caused by incorrectly oriented caps. All 3-lane ROTOPRINT machines are supplied with a water-cooled wheel in their basic equipment. Outstanding register accuracy is attained by the constant temperature of the jig carrier. Together with the H-RTI 21-150 printing unit, sophisticated motifs with precise print images for years to come and consistent quality are attained. Rapid color, cliché and motif changes and simple and tool-free operation reduce the ROTOPRINT‘s tooling times.

Request for a quote

TAMPOPRINT GMBH

Germany

A real Plug-and-Play fully automated system which is ready to use anywhere at any time. You only need electricity, gas and air supply, then connect our CLOSURE PRINT COMPACT and production may start. No service technician for commissioning and no special qualified personnel at the customer are necessary. A high-precision, space-saving rotary pad printing fully automated system for small batch sizes. Feeding solution, parts transport for further processing to the point of a complete system solution − everything from one source.

Request for a quote

TAMPOPRINT GMBH

Germany

The ENCODER machine series was specifically developed for integration in all kinds of automated systems. Variable control possibilities: For the EP series we offer three different electronic control possibilities. Variable installation positions: The ENCODER EP/1 models, equipped with a piston on the ink/ doctoring cup and adequate overhead control, guarantee all print positions. Fitted with the ENCODER aluminium stand, the ENCODER EP/1 have a free choice of positioning within 360° and the distance to the printing component can be additionally adjusted with a handwheel.

Request for a quote

TAMPOPRINT GMBH

Germany

The SEALED INK CUP 90 Q is a single-color pad printing machine for the realization of oblong print images that are larger than the ink/doctoring cup used. Designed as an entry-level model, this machine offers a good basis for a variety of applications. As basic equipment this pad printing machine contains a base frame with practical storage space. This also ensures a stable stand and leads to high stability. Flexibility is provided by the height-adjustable angle table, which allows quick changeover to components of different sizes. With the user-friendly touch panel many machine parameters and functions can be controlled and set on the display.

Request for a quote

BOSTON INDUSTRIAL SOLUTIONS, INC.

United States

The Natron MG Series is a 2-part Pad printing ink for glass, metal, ceramics, PET (PETE), Tritan, poly carbonates, and hard plastics. This pad printing ink requires the i-240x hardener and a solvent (Type TSM or A-TPV) to pad print on glass. For screen printing, this ink uses the type TSR or the TSS solvents. Once the ink is mixed with these two components, the prints are exceptional. The MG inks score exceedingly high on adhesion, gloss, and opacity. It comes in a variety of opaque mixing colors and special effects. The MG series inks are also Non-Toxic, free from heavy metals, high density, high opacity inks. -High gloss and opacity -Resistance to weather elements -High abrasion resistance -Excellent chemical resistance -Commercial dishwasher resistant -MG series ink is dishwasher safe once heat cured

Request for a quoteResults for

Pad printing on stoppers - Import exportNumber of results

31 ProductsCountries

Company type