- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- perforations

Results for

Perforations - Import export

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles Clamping device with 6 or 8 workpieces Processing the ends and connections on MFZ Processing of deep hole drilling 4-6 spindling on SAMAG shaft drilling machines

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

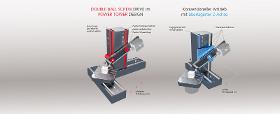

DIVERSE TASKS REQUIRE FLEXIBLE MACHINE CONCEPTS, SPECIAL QUESTIONS REQUIRE INDIVIDUAL SOLUTIONS AND EFFICIENT PRODUCTION REQUIRES SECURE PROCESS CHAINS, IN SHORT: TFZ – FIT 2 TASK! With the very successful and established TFZ series, SAMAG has been a guarantee for task-specific solutions and tailor-made machines for years. At the same time, the well-thought-out machine structure of the TFZ enables optimal deep drilling and highly dynamic milling with just one clamping and thus efficiency par excellence. The unique design principle always ensures optimal accessibility, a minimally short distance between the swivel bearing and the processing point and extremely stable tool guidance for high-precision work, even when high lateral forces occur. No matter where you set your priorities in the manufacturing process, we are able to technologically align our TFZ machine accordingly and you can rely on “your” TFZ solution to fit perfectly, today and in the future.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

“The deflection (∆) of the tool tip (TCP) due to the machining force (F) depends to the third power ( l 3 ) of the length ( l ) of the distance TCP to the front bearing axis (A), in relation to the bending stiffness (E · I) “ Or: the shorter l , the smaller ∆ and the higher the precision

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Robust, long-lasting machine for individual part and small series production Very good accessibility to the processing unit and to the workpiece clamping Crane loading possible Up to 3 mobile tool rests Service and maintenance-optimized accessibility to all machine components Crane hook machine, therefore short set-up times OUR TBM mono IS THE SPECIALIST FOR INDIVIDUAL PARTS AND SMALL SERIES. SPECIAL FEATURES: VERY SMALL DRILLING DIAMETERS WITH A LARGE DRILLING DEPTH AT THE SAME TIME

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

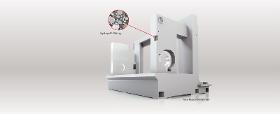

OUR MFZ SERIES CANNOT SHAKE ANYTHING SO EASILY. A SOLID FRAME CAST WITH HYDROPOL ® AND THE CLOSED CONSTRUCTION GUARANTEE THE HIGHEST PRECISION THROUGH BEST VIBRATION DAMPING AND TEMPERATURE STABILITY. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity. ROCK SOLID DESIGN – THE ADVANTAGES OF A ROCK SOLID MACHINE BED OVER STEEL AND CAST CAST FRAME: Closed construction – analyzed and optimized according to FEM Optimal power flow

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Complete machining on MFZ including axis drilling 2-spindle solution with independent X, Y and Z axes

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

KALSEDON STONE

Turkey

SIMPLE APPLICATION, KALSEDON STONE PANEL PREFERED TO MAKE YOUR SPACES BEAUTIFULL WITH SPECIAL DESIGN

Request for a quote

FORM CREATIONS

Poland

Collapsible small plexi display. Plastic hooks. Perforation. Folds flat. Easy assembly.

Request for a quote

BOGRAMA AG

Switzerland

The most universal and most sold model by far for the mid capacity range to 10,500 cycles/h. Simple operation from touchscreen Integrated controller for infeed hole punching Available in two working widths.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quote

PSAPLAST - PLÁSTICOS SANTO ANTÓNIO, LDA.

Portugal

1,2x1m Pallet When empty they nest in each other to reduce the volume. Stacks by turning 180º. Produced on request for a minimum order quantity of: 4x195 = 780 units Grid dimension at the base: 10x10mm

Request for a quote

TEKNOFOAM AKUSTIK IZOLASYON SANAYI VE TICARET LIMITED SIRKETI

Turkey

2000 perforated acoustic wood panel is not designed to provide sound insulation. These types of panels are used to reduce sound echo and improve sound quality. The holes allow sound to enter and dampen the panel, reducing reflected sound waves and providing clearer sound quality. There is also usually acoustic material behind the panel, which provides better insulation performance. 2000 perforated wooden acoustic panels are used in many areas that require sound insulation, for example, they can be used in places such as conference rooms, recording studios, offices, schools, cinemas and restaurants. Moreover, they are available in various colors and sizes and can be chosen to suit the decoration.

Request for a quote

TECHNIC MACHINES

Turkey

Our sheet metal Perforating machine is feasible for working different raw material. We provide necessary adjustments on our perforation machine lines according to requested work of our customers for having final perforated sheet results according to our customers or their market demand. Perforated sheet metals is preferred in many different areas and industries. We can say these industries and field such as, electric and electronic, air condition, refrigerator, machinery, automative, filter production, furniture, lighting, shelfs, racks, walking platforms, filers and etc. Perforation Machine Main Units – Press Feeding Unit – Punching Unit – Cutting Unit – Stacking Unit – Recoiling Unit We provide our perforated sheet machine line according to demand of our customers with different perforated sheet working thickness and width etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIFLEX-HYDRAULIK GMBH

Germany

The use of gas conducting hoses (e.g. air, nitrogene etc.) requires the perforation of the cover. The PR 10.2 tool provides an easy solution for quick pin pricking of the cover. Market established UNIFLEX quality gives you a precision tool for hoses up to an outer diameter of 45 mm (1,75 inch).

Request for a quote

PE ARTHA-S

Ukraine

Features of perforated film The main characteristics of Micro perforation: the bore diameter is 0.5 mm; material width from 100 to 1000mm; material density from 20 to 100 microns Macro (Europerforation): the bore diameter is 0.5 mm; material width from 200 to 500 mm; material density from 25 to 100 microns. The air exchange:Due to the openings, products and goods retain their quality while being securely packaged. Abrasion resistance:The material is highly durable and resistant to temperature changes, and the conveniently positioned tear-off lines make it easy to unpack. Quick removal of excess moisture:The perforated packaging ensures air circulation. Vegetables and baked goods retain their freshness longer and moisture does not accumulate inside the pack. Universality:The range of applications is not limited to goods in the food group but can include household chemicals, plants, non-food products and others.

Request for a quote

PE ARTHA-S

Ukraine

This product is suitable for producers of freshly cut flowers (greenhouses, wholesalers). TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 30 to 40 micrometres Film Width from 100 to 500mm Spool Diameter from 200 до 400 mm Density 0,91 g/cm3 Kinetic Friction Coefficient 0,2 Thermal shrinkage 120 С, in 5 minutes no more than 2-4% Turbidity no more than 3% Welding strength at 130 С, 1 bar, 1 sec 2,5 - 3,0 N/15 mm Welding range at 1 bar, 1 sec 105 -140 С Gloss at 450 %, no less than 85% Hole diameter 5 mm Advantages of the film with macro perforation: Air exchange – due to the presence of holes, products and goods preserve their qualities, while being in reliable packaging. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in the packaging. Wear resistance – the material has high strength and resistance to temperature changes. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

This product is suitable for producers of freshly cut flowers (greenhouses, wholesalers). TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 30 to 40 micrometres Film Width from 100 to 500mm Spool Diameter from 200 до 400 mm Density 0,91 g/cm3 Kinetic Friction Coefficient 0,2 Thermal shrinkage 120 С, in 5 minutes no more than 2-4% Turbidity no more than 3% Welding strength at 130 С, 1 bar, 1 sec 2,5 - 3,0 N/15 mm Welding range at 1 bar, 1 sec 105 -140 С Gloss at 450 %, no less than 85% Hole diameter 5 mm Advantages of the film with macro perforation: Air exchange – due to the presence of holes, products and goods preserve their qualities, while being in reliable packaging. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in the packaging. Wear resistance – the material has high strength and resistance to temperature changes. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 30 to 40 micrometres Film Width from 100 to 500mm Spool Diameter from 200 до 400 mm Density 0,91 g/cm3 Kinetic Friction Coefficient 0,2 Thermal shrinkage 120 С, in 5 minutes no more than 2-4% Turbidity no more than 3% Welding strength at 130 С, 1 bar, 1 sec 2,5 - 3,0 N/15 mm Welding range at 1 bar, 1 sec 105 -140 С Gloss at 450 %, no less than 85% Hole diameter 5 mm Advantages of the film with macro perforation: Air exchange – due to the presence of holes, products and goods preserve their qualities, while being in reliable packaging. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in the packaging. Wear resistance – the material has high strength and resistance to temperature changes. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 30 to 40 micrometres Film Width from 100 to 500mm Spool Diameter from 200 до 400 mm Density 0,91 g/cm3 Kinetic Friction Coefficient 0,2 Thermal shrinkage 120 С, in 5 minutes no more than 2-4% Turbidity no more than 3% Welding strength at 130 С, 1 bar, 1 sec 2,5 - 3,0 N/15 mm Welding range at 1 bar, 1 sec 105 -140 С Gloss at 450 %, no less than 85% Hole diameter 5 mm Advantages of the film with macro perforation: Air exchange – due to the presence of holes, products and goods preserve their qualities, while being in reliable packaging. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in the packaging. Wear resistance – the material has high strength and resistance to temperature changes. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 20 to 40 micrometres Film Width(micro per.) from 150 to 1000mm Film Width(macro per.) from 150 to 500mm Film Width(without per.) from 150 to 1200mm Number of printing machines 4 pieces Minimum Width Seal from 180 to 1200mm Print Pitch to 600mm Lineature from 60 to 124 lpi Spool Diameter from 200 to 1000mm Number of colours from 1 to 8 Advantages of the film with PRINTING perforation: Printing a logo –will provide recognition of a trade mark. The convenience of packaging –the film is simply soldered and its usage is optimal for automatic packaging lines. Air exchange –due to the presence of holes, products and goods preserve their qualities while being in reliable packaging. Fast removal of excess moisture –products keep the freshness longer and moisture does not accumulate in the packaging. Wear resistance –the material has high strength and resistance to temperature changes. The minimum batch of delivery is 100 kg

Request for a quote

PE ARTHA-S

Ukraine

TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 20 to 40 micrometres Film Width(micro per.) from 150 to 1000mm Film Width(macro per.) from 150 to 500mm Film Width(without per.) from 150 to 1200mm Number of printing machines 4 pieces Minimum Width Seal from 180 to 1200mm Print Pitch to 600mm Lineature from 60 to 124 lpi Spool Diameter from 200 to 1000mm Number of colours from 1 to 8 Advantages of the film with PRINTING perforation: Printing a logo –will provide recognition of a trade mark. The convenience of packaging –the film is simply soldered and its usage is optimal for automatic packaging lines. Air exchange –due to the presence of holes, products and goods preserve their qualities while being in reliable packaging. Fast removal of excess moisture –products keep the freshness longer and moisture does not accumulate in the packaging. Wear resistance –the material has high strength and resistance to temperature changes. The minimum batch of delivery is 100 kg

Request for a quote

PE ARTHA-S

Ukraine

This product is suitable for producers of freshly cut flowers (greenhouses, wholesalers, retail chains), flower retailers and florists. TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 25 to 100 micrometres Sheet size is individual It is possible to print in your design Advantages of transparent sheets: Wear resistance – the material has high strength and resistance to temperature changes. The convenience of packaging – you can pack plants in a package as quickly and beautifully as possible and transfer them to the client. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

This product is suitable for producers of freshly cut flowers (greenhouses, wholesalers, retail chains), flower retailers and florists. TECHNICAL SPECIFICATIONS : Film Material BOPP/CPP Film Density from 25 to 100 micrometres Sheet size is individual It is possible to print in your design Advantages of transparent sheets: Wear resistance – the material has high strength and resistance to temperature changes. The convenience of packaging – you can pack plants in a package as quickly and beautifully as possible and transfer them to the client. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

TECHNICAL SPECIFICATIONS : Film Material BOPP/СРР Film Density from 25 to 100 micrometres Bottom Width from 70mm to 200mm Upper Width from 200mm to 700mm Height: from 200mm to 1000mm Advantages of transparent perforated cone packages: Air exchange – due to the presence of holes in the package, a favourable microclimate is created for the storage and transportation of plants. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in packaging. Wear resistance – the material has high strength and resistance to temperature changes. The convenience of packaging – plants can be packed as quickly and beautifully as possible in a package. Protection of a plant – the package gives a plant an optimum form and keeps it from mechanical damage. The minimum batch of delivery is 50 kg

Request for a quote

PE ARTHA-S

Ukraine

This product is suitable for producers of flowers in pots (greenhouses, wholesalers). TECHNICAL SPECIFICATIONS : Film Material BOPP/СРР Film Density from 25 to 100 micrometres Bottom Width from 70mm to 200mm Upper Width from 200mm to 700mm Height: from 200mm to 1000mm Advantages of transparent perforated cone packages: Air exchange – due to the presence of holes in the package, a favourable microclimate is created for the storage and transportation of plants. Fast removal of excess moisture – products keep the freshness longer, and moisture does not accumulate in packaging. Wear resistance – the material has high strength and resistance to temperature changes. The convenience of packaging – plants can be packed as quickly and beautifully as possible in a package. Protection of a plant – the package gives a plant an optimum form and keeps it from mechanical damage. The minimum batch of delivery is 50 kg

Request for a quoteResults for

Perforations - Import exportNumber of results

253 ProductsCountries

Company type

Category

- Boxes and trays, storage (34)

- Films for packaging (20)

- Perforation of steels and metals (18)

- Grids, gratings and wire mesh (15)

- Perforation of rubber and plastic (10)

- Mechanical engineering - custom work (9)

- Knives, industrial (5)

- Boxes, plastic (4)

- Finishing and binding - machinery and equipment (4)

- Plastics - machines and material for industry (4)

- Plates, perforated - ferrous metal (4)

- Steels and metals - machining (4)

- Bags, plastic (3)

- Blades and knives, industrial (3)

- Display units for exhibitions (3)

- Dustbins, waste bins (3)

- Aluminium sheets and bands (2)

- Bags (2)

- Bathroom accessories (2)

- Bearings - ball, needle and roller (2)