- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic thermoforming machines

Results for

Plastic thermoforming machines - Import export

KUZEY GLOBAL

Turkey

Thermoforming machines for disposable food cups and sheet line extrusion , ofset printing machines

Request for a quote

TECHNIC MACHINES

Turkey

We supply our plastic thermoforming machine for different product solution. For example cup, dish, plate, lid, bowl, medical, clamshell etc. We have also different production capacity options on our thermo molding machine. We supply the quality, international standards and performance together with our plastic thermoforming machines. You will have high production capacity with low power consumption with our thermoforming machines, with our advanced software and technology. You can achieve easily to European Quality Level on your products, with the help of our European technology. Just contact with us for your thermoforming machine research, we will provide the optimum solution for your machine research.

Request for a quote

FRIMO GROUP GMBH

Germany

One Concept, Many Applications FRIMO EcoForm machines provide state of the art technology that stems from more than 25 years of thermoforming expertise. These machines have the most modern technology in a compact, user-friendly form. They are designed as standardized single-station machines for vacuum forming and vacuum laminating films and sheet materials. They can also be used in the IMG ( In-Mould Graining) process. EcoForm Thermoforming Machines for Plastic Sheets EcoForm thermoforming machines for plastic sheets are the result of continuous product development and improvement and offer a concept superior in many technical details and convincing in terms of economic efficiency, operating convenience, and process reliability.

Request for a quote

RIDAT

United Kingdom

Ridat’s Roller Cutting Press (RCP) machines are designed to cut plastic thermoformed sheet, rubber, leather, board, foil and other gasket material, plastic foam, plastic coated or impregnated fabric. Production steps are as follows: Vacuum formed sheet is placed upside down on a cutting mould Board is placed on top and the sandwich is fed through the press A pair of pressure rollers causes the sandwich to press against the steel rule knife within the cutting mould thereby individualising the material. Key machine features include: Solid steel cutting pressure rollers Both pressure rollers are driven Electric motor gearbox drive Dual Control sequence switching - Jog or Run Steel Conveyor rollers CE Mark

Request for a quote

PRO COUPE INDUSTRIES

France

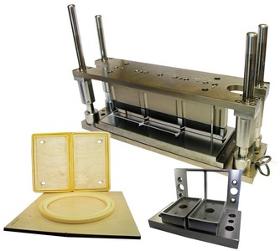

Thermoform tooling for ULMA®, MULTIVAC®, MECAPACK®, CFS® TIROMAT®

Request for a quote

KUZEY GLOBAL

Turkey

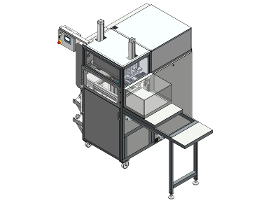

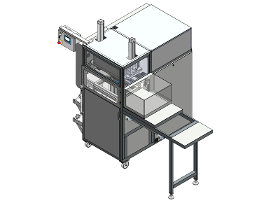

CMK 95/65-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, flower pots and seeding trays. Machine has the bigger forming area than 85 series station machine, and it is better if high is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 95/65-S3 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, ete. Machine has the bigger forming area than 85 series station machine, and it is better if high capacity is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 85/55-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or multi compartment containers, hinged lid containers, leaking-proof containers, hole-punch containers, egg viyole, flower pots and seeding trays. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors Automatic lubrication of moveable parts which is activated as perthe specified time space

Request for a quote

KUZEY GLOBAL

Turkey

CMK 85/55-S3 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, ete. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 75″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings

Request for a quote

KUZEY GLOBAL

Turkey

Synchronized forming and cutting by tilting movable lower platen to 80 degrees Sheet pitched by double toothed chains and move on abrasion resistant slide plates; Lengthened pan design allows to reach optimum forming heat without using pre-heater machine Upper and lower Mold ; heats control by indivudial Thermoregulation device Fine adjustment for mold by electric drive. Traversing and tilting moving system of mould PLC for control the line operation and supervise working parameters Opportunity to set one or more forming cycles without cutting by pneumatic drive High production capacity with resistant to high speed Strong and vibration free main body Double inlet- outlet system for fast cooling by increasing water discharge. Energy analyzer which gives amount of the electric consumption Cutting adjustment possible by digital meter ,controlled by PLC. Plug asist motor

Request for a quote

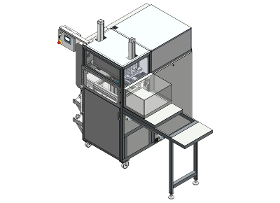

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

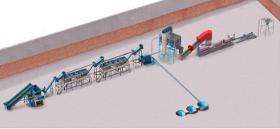

TECHNIC MACHINES

Turkey

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our rattan extruder machines have different production capacity range and also capable to produce different rattan sizes, so that we can match different demand. You can produce with our rattan extruders different final product such as furniture and decoration etc. Plastic rattan raw material is mostly PE. PE has the highest stability if you compare with other plastic rattan raw materials alternative. Other most common raw materials for plastic rattan extrusion are PVC and PU. Where you can use plastic rattan ? - Rattan Chair - Rattan Table - Rattan Sofa - Rattan Coffee Table - Rattan Bench Just contact with us for your rattan extrusion machine research, we will provide the optimum solution for your research.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

These materials offer numerous advantages when working with them, which is why they are increasingly being used in comparison to other alternatives such as metals. Technical applications require parts with very specific features. Research and development thus play an important role in obtaining innovative items.

Request for a quote

RIDAT

United Kingdom

Ridat Semi Automatic (SA) Vacuum Forming Machines offer, as standard high specifications, consistent production and a wide range of standard models and readiness to respond to requests for bespoke specifications. Fully automatic moulding processing sequences with manual placement of thermoformable sheet and removal of the vacuum formed product. Key machine features include: Ceramic heaters with multi-zone heater control for balanced heat Power assisted and timer controlled heater box movement Hinged clamp frame - powered by two air cylinders Mould chamber fully sealed to maintain vacuum pressure High capacity vacuum reservoir and pump for instant vacuum supply Microprocessor Controls and HMI Display CE Mark

Request for a quote

RIDAT

United Kingdom

Ridat’s Automatic Vacuum Forming Machine range with Double Heater (AVF) is designed for consistent production of all commonly used thermoformable material of up to 12 mm thickness. Robust construction with an automatic vacuum forming cycle and user-friendly touch screen control of all processing features. Key machine features include: Top and bottom heaters ensure balanced heat distribution with minimal material stress. The dual ceramic heaters also enable a variety of material sheet types (such as PVC, PP, PS, APET, GPET, HDPE, ABS) to be vacuum formed. Clamp frame and mould table are both raised by four cylinders and guided by rack and pinion mechanism for smooth and parallel movement Fully sealed mould chamber to maintain vacuum pressure and facilitate pre-blow and bubble Photo electric sensor to control sheet sag and bubble height High capacity vacuum reservoir and pump for instant vacuum supply High velocity turbo fans to cool the vacuum formed sheets CE Mark

Request for a quote

BETA PLASTIK VE VAKUM

Turkey

Our company can manufacture various thermoformed ABS plastic parts which our customers require. We can manufacture aluminium mould and after we manufacture ABS sheet by our extrusion line we can thermoformed the plastic sheets. Finally we use our 3-axes and 5- axes CNC machine that trim the products to finalize. Our company working with various company from different sectors. Automative ABS plastic parts,Medical ABS plastic parts etc.

Request for a quote

YENIMAK MAKINA

Turkey

Maximum Mould Size : 650x435mm Maximum Forming Area : 620x405 mm Maximum Cutting Area : 630x405 mm Negative Forming Depth : 120 mm Maximum Sheet Width : 710 mm Minimum Sheet Width : 300 mm Upper Heater Heating Power : 32.5 kW Lower Heater Heating Power : 32.5 kW Continuous Power Consumption : 40 kW Total İnstalled Power : 80 kW Vacuum : 105 m³/h Dry Running Cycle : 60 cycle/min Weight (approx.) : 7000 kg Length : 7000 mm Width : 2300 mm Height : 2500 mm Required Compressor : 3 m³/min Required Cooler : 20000 kcal/hour

YENIMAK MAKINA

Turkey

Maximum Mould Size : 850x650 mm Maximum Forming Area : 820x620 mm Maximum Cutting Area : 820x620 mm Positive Forming Height : 160 mm Negative Forming Depth : 160 mm Maximum Sheet Width : 910 mm Minimum Sheet Width : 400 mm Upper Heater Heating Power : 71 kW Lower Heater Heating Power : 71 kW Continuous Power Consumption : 142 kW Total İnstalled Power : 225 kW Vacuum : 250 m³/h Dry Running Cycle : 60 cycle/dak Weight (approx.) : 14000 kg Length : 10300 mm Width : 2800 mm Height : 3000 mm Required Compressor : 8 m³/min Required Cooler : 50000 kcal

METZNER MASCHINENBAU GMBH

Germany

With automatic continuous punching machines, machine and tool merge into a high-performance system with high output and remarkable flexibility. Whether sealing profiles for the automotive industry, applications for furniture, or household appliances – complex trimming is often required here. Thanks to the Metzner automatic throughfeed punching machines, processing operations such as contour cutting, drilling and milling can be integrated into a throughfeed system. All these machines store all machining parameters and machine settings in a machining recipe. When starting production, an integrated barcode scanner activates all presettings on the basis of the working papers and simultaneously reports the correct tool and material on the machine display. The barcode also contains the required quantities and lengths. Thanks to well thought-out quick-change systems, tools and materials are generally changed within no more than 30 seconds, minimizing downtimes.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Preparation of the material components under vacuum and injection into an evacuated mold.

Request for a quoteResults for

Plastic thermoforming machines - Import exportNumber of results

26 ProductsCompany type

Category

- Thermoforming, plastics - machinery (14)

- Packing and packaging - machinery and equipment (5)

- Plastic material processing (3)

- Wrapping machines (3)

- Extrusion, plastics - machinery (2)

- Punching machines, plastic (2)

- Aerospace and aeronautics - construction (1)

- Cutting, plastics - machinery (1)

- Injection, plastics - machinery (1)

- Milling and turning of rubber and plastic (1)

- Plastics - machines and material for industry (1)

- Plastics moulding (1)