- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic conveyor systems

Results for

Pneumatic conveyor systems - Import export

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The capacity, size and shape of the storage barrel, allowing the storage of powders, granules or other materials, can be customized to meet customer needs. The silo can be used in conjunction with a pneumatic conveyor system/air distribution equipment. It can be optionally equipped with material level sensors, pneumatic bridge breaker, maintenance hatch, ladder guardrail and maintenance platform. The silo can also be cooled by introducing cold air or keep the heat thanks to the electric heating system.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Powder suction/powder receiver hoppers use air to convey the powdery material and can be specified in butterfly valve type and rotary valve type. The advantage of air conveyor/pneumatic conveyor system is the small residual amount of pipeline, which ensures that the pipeline is empty between the production of each batch to meet food production regulations. The powder suction/powder receiver hoppers are designed to be quickly dismantled and cleaned, without tools, which is convenient for maintenance to comply with food regulations. The powder suction hoppers/powder receiver can be installed on storage barrels, mixers, packaging machines and mills, they are suitable for powdered food materials, chemicals and plastics. There are many options for the top filter to accommodate various feeding systems.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Feeding of filtered-out materials to silo systems over long distances (up to 700 m). Pneumatic medium-pressure conveyor systems For the conveying of filtered-out materials such as wooden splinters and wood dust or for the conveying of products in the derived timber products industry with large conveying quantities over great distances. Pneumatic medium-pressure conveyor systems are economical, reliable and enable flexible adaptations to individual conveying routes. The conveying air stream is generated by a rotary piston compressor. As opposed to fans, these have almost vertical characteristic curves; i.e. the volumetric flow rate remains almost constant as the pressure in the conveying system increases. This ensures safe material transport. Special cellular wheel sluices are necessary for channelling the conveying material into the conveying stream, such as knife gates for derived timber products. Cyclones, filters or combinations of the two are used to separate the conveying material from the conveying stream. The economical conveying lengths lie between around 150 and 750 m. The loading of the conveying stream can amount to up to 5 kg/m³ and essentially depends on the grain size, density and form of the material to be conveyed.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For the conveying of filtered-out materials to silos or containers. Pneumatic low-pressure conveyor systems For the conveying of filtered-out materials to silos or containers and for conveying distances of up to 200 m. The conveying air stream is generated by one or more fans. Product description Pneumatic low-pressure conveyor systems can be implemented as a single-pipe system or a ring system. In the case of the single-pipe system, a final separator in the form of a filter or a cyclone is always necessary. In a ring system the conveying air is driven in the ring. In this case the silo or container acts as the separator. Light dust particles that are not separated in the silo or container initially remain in the circulation. With most materials the fine dust particles tend to attach themselves to the coarser ones and are thus separated with them. Hence, a concentration of the fine dust particles in the conveying stream is avoided as far as possible. The loading of the conveying stream essentially depends on the grain size, density and form of the material to be conveyed. As a guiding value, one may assume 250 - 300 g/m³. Higher loads are possible under certain conditions. In cases where there is a high amount of material, e.g. in planing works, where the splinters are directly removed and transported away for further use, this can also be realised with a ring system and several containers. Switchover takes place automatically when the container signals that it is full. Containers are exchanged during operation.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec pneumatic conveyor S-WS is used when, for example, local conditions do not allow the use of a spiral conveyor, for example when the minimum radius of a flexible conveyor can not be met or to overcome larger conveyor lines. Here are some features of the pneumatic conveyor: - Suitable for conveying granules and dry powders - Large filter surface - Filter cleaning by means of compressed air - adjustable interval filter cleaning - High throughput - Ideal for long conveyor lines - Fields of application: plastics and food industry as well as chemical and environmental sector. - Different filter sizes up to 10 m2

Request for a quote

FEMIA INDUSTRIE

France

Provides the product transfer from a piece of equipment located upstream to a piece of equipment located downstream. Can be adapted according to your needs and capacities.

Request for a quote

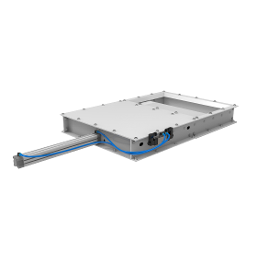

HO-MA GMBH

Germany

Its flexible design makes the flush-grid belt conveyor particularly compact and its curve radius can be adjusted.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

The necessity to spread/separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space. Coating processes also benefit by separating product and reducing rejection rates.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to divert the product both for pressurized conveying and for aspirated pneumatic conveying systems

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to centrifugally separate dust - air mixture and generally is designed as a dust receiver in pneumatic conveying systems

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

ASETAL BELT CONVEYOR Standard Widths 82,6 mm, 114,5 mm Standard Gear Dia Ø 109 mm Standard Lengths 1000 mm - 6000 mm Upon Request Lengths Optional.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan is a world leading supplier of complex centralised material feed systems. Each system is designed to suit the customer by taking into account individual factors such as throughput, materials types, and plant layout. A wide selection of loaders with a variety of conveying options, controls, blowers, and filter techniques allow the creation of the optimum system for the customer’s facility.

Request for a quote

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Osmak manufacture standard and costum designed 2 or 3 parted conveyor stations with highest quality materials in according to related international standards. Please do not hesitate to contact us for more information.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

200 meters metal scrap conveyor. It was designed, manufactured and assembled by Tıkır Makina by the world-famous oven manufacturer company, together with 10 pant chutes and one rotary chute. It was commissioned in 2021. The scrap conveyor, which allows the scraps coming out of the presses to flow to the line through pant chutes, fill the baskets at certain points beforehand through the rotary chute. While the scrap conveyor works effectively in this way, it provides efficiency, time savings and safety. The scrap conveyor occupies a very important place especially in the metal processing industry. However, it is possible to design suitable for all sectors. Apart from scrap conveyor, we can produce belt conveyors, pallet conveyors, chain conveyors and roller conveyors. We are waiting for you. Contact us.

Request for a quote

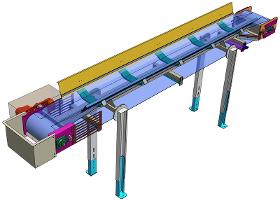

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Osmak Rulo manufactures 5, 6, 7, 8, 9, 10, 11, 12, 14, 15 meters standard size loading conveyor belts with special damping system, also desired lengths are available upon request.The bands are manufactured with properties that can work back and forth. The upper and lower band lifting system, braking and a geared motor is used. 380 volt or 220 Volt (single phase) electrical motors used on Osmak Conveyor belts. Conveyor belt width 600 mm the standard production. However, the width of the band can be narrower or wider upon request. Please do not hesitate to contact us for more information. Custom design orders are welcome with technical drawing.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a conveying speed of up to 3.0 m/s, flexibility and hardiness are also demanded of the curves. The area of application for the Motion06 Curved Belt Conveyor is in the continuous or clocked transportation of pieces of luggage and packages with changes in direction. When developing the Curved Belt Conveyor, the highest priority was given to the ‘small space requirements’ and a wide range of standard measurements or customerspecific measurements for integration into new or existing systems. The entire product range is a modular design and is designed based on stateoftheart technology. A consistent appearance for the operation of a wide variety of weight classes and product sizes is available worldwide. Structural Lengths Short structural lengths of approx. 600 mm conveyor length and, for example, belt width of 1.000 mm possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

Belt conveyor is one of the carrying or transporting mechanisms of a recycling or waste management installation. Depending on the complexity of the waste materials mixture, the looping belt requires robust and durable properties to resist impact, wear and leaking of oil and grease.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

When your production or recycling process includes different levels in height or your facility is compact, implementing a state of the art elevator conveyor is an efficient solution.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

Like belt conveyors, also a chain conveyor is engineered with the purpose of transporting materials. Transporting materials on this type of conveyor commonly proceeds in a horizontal way, but also vertically over a short distance to a higher level is possible.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

It is a system that enables the compressed scrap to be transported to the container by conveyor.

Request for a quote

FERAG AG

Switzerland

With the continuous and seamless conveying system Easychain, even narrower curve radii can be realized than with the „bigger brother“ Deniway. This is particularly noticeable when complex, three-dimensional layouts are required. In addition, the highly modular system can be quickly installed and converted. The system is based on rollers that reduce friction and thus both energy consumption and wear. That is why Easychain is robust, reliable and largely maintenance-free.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

Roller conveyor disc transfer line is used for the transfer of yarn bobbins. It has been specially designed. It is a turnkey project with barcode readers, bagging machine, robot centering and separator systems and diameter measuring mechanisms. It was designed by our talented engineers in Tıkır Makina design offices, manufactured in our 3000 square meter indoor facility, and assembled on site by our trained personnel. Tıkır Makina has been producing vertical and horizontal transfer systems for the industry since its establishment. It has the ability to produce conveyors, elevators, autonomous driverless forklifts and special design projects according to your needs. We have worked with world giant automotive brands such as Ford, Toyota and Fiat. It has cooperated with world-renowned textile companies and has been a solution partner in the transfer systems of dozens of companies in Turkey, including textile, food and heavy industry. We are ready to listen to you.

Request for a quote

FERAG AG

Switzerland

Skyfall combines conveying, buffering, sorting, consolidating and production processes in one system. It is based on shuttles and trolleys combined with application-specific load carriers, along with the use of gravity. Skyfall can be used in the third dimension to save space, thus freeing up valuable floor area for value creation processes. With its extensive range of functional accessories, the system has universal applications and is readily expandable with additional functions and capacities.

Request for a quote

TRAKTECH

Spain

Traktech’s air conveyors are an effective way to move PET blown bottles, guaranteeing quick and agile movement of the bottles with no risk of snagging or contamination. Traktech, being a specialist in the handling of empty bottles at the start of the filling line, has accumulated a great deal of experience in different systems for moving empty bottles. Traktech’s air conveyors blow the bottles just below the neck guide that holds the bottle by the ring, making contamination by blowing into the bottle impossible, as between the blowing orifices and the bottle mouth there is a Teflon guide and the ring of the bottleneck that stops air from entering the PET bottle. Traktech’s air conveyors also have an automatic system to adjust the neck guide and side guides, that can work with electrical actuators or pneumatic pistons. In both adjustment systems, the air conveyors ensure perfect adjustment of the guides, avoiding bottle transport jams, which can occur with other adjustment systems.

Request for a quote

FERAG AG

Switzerland

The Deniway plate chain conveyor is based on a chain supported by low-friction rollers. Thanks to low rolling resistance, very long conveying distances can be achieved without troublesome transfers and using only a few drives. The 3D layout capability allows continuous material flow over several levels. The system is designed as a modular kit, so it scales easily. A line can thus be modified and extended with very little effort. In this way, all processes taking place in a conveyor can be linked together. The virtually maintenance-free design guarantees a long service life with low running costs and high efficiency.

Request for a quote

SELF TRUST - THE ROMANIAN CONVEYOR FACTORY

Romania

CITCOnveyors, division of SELF TRUST Romania, offer a wide range of gravity and powered roller conveyors, to suit customer individual requirements. The modular design allows for cost-effective integration of units to create highly efficient and adaptable handling systems. Other benefits: modular allowing flexibility and future expansion, wide range of auxiliary interfaces available, cost-effective, high quality, robust, low maintenance CITCOnveyors offers: Powered Conveyors, Gravity Conveyors, PVC Rollers Conveyors, Horizontal Conveyor, Inclined Conveyor, Curved Roller Conveyor, Pallet Roller Conveyor and more. For more types of conveyors please contact us!

Request for a quote

SELF TRUST - THE ROMANIAN CONVEYOR FACTORY

Romania

CITCOnveyors - division of SELF TRUST Romania - offers: Horizontal Conveyor, Sloping Conveyor, Inclined Conveyor, Elevator Conveyor, Modular Belt Conveyor, PVC Belt Conveyor, Polyurethane Belt Conveyor, Modular Belt Conveyor, Curved Conveyor, Machine Integration on Conveyor Systems and more. With a large portfolio and a wide range of areas in which it has implemented projects, the most important solutions are in Airport Industry, Automotive Industry, Logistics Industry, Food Industry, Drinks Industry, White Goods Industry, Waste Management Industry. For more types of conveyors please contact us!

Request for a quoteResults for

Pneumatic conveyor systems - Import exportNumber of results

35 ProductsCountries

Company type