- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic transport

Results for

Pneumatic transport - Import export

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The MICRODYN is an abbreviation of the words "MICROclassificateur DYNamique". It is composed of one or several variable speed classification rotors, clean air for rinsing and a waste discharge spout. It is particularly effective for the production of very fine powder from a pulverulent produced by an existing grinding process. It is fitted as standard on the PAS Integrated Classifier mills. The fine particles are transported by the pneumatic circuit towards a finished product collector (cyclone or filter for finer products). The oversized particles are evacuated out of the circuit along a skirt or through a rotary valve.

Request for a quote

ROBINSON CO.

Turkey

It is used to transport the products pneumatically to different points over a single line. It allows to change direction during transportation. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ENVEA

France

Especially designed for continuous measurement of velocity of solids and particles such as granulates, powders and dusts, which are transported in free fall or in pneumatic transport. Uses triboelectric correlation technology. • plugin sensor for easy retrofit • continuous speed measurement of solids • measurement directly in the conveying stream • material independent measurement

Request for a quote

ENVEA

France

Continuous flow measurement of powder or granules in high pressure densephase conveying. Designed to measure solid flows during pneumatic dense phase transport. The sensor measures density and speed. • pressureresistant up to 64 bar • maintenancefree • contactless • ATEX category 3 approved

Request for a quote

ENVEA

France

Continuous solids mass flow measurement in densestream conveying and high levels of throughput. Designed to measure solid flows during pneumatic dense phase transport. The sensor measures density and speed. • unlimited throughput volumes can be measured • no wear thanks to the ceramic inner pipe • simple retrofitting • maintenancefree

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

To handle abrasive media at normal bending radiuses and high vacuum. The standard version for a large number of very different applications in hydraulic or pneumatic transport. Temperature-resistant from –35°C to +90°C. Construction: Abrasion-resistant, antistatic tube Optional: Embedded copper wire Tension and pressure-resistant fabric inlays Concealed steel spiral UV, ozone and weather-resistant cover Interior and exterior smooth, fabric patterned Sold by the roll or in fixed lengths with cuffed ends and/or widened hose endings. Version without spiral also available. Other versions and dimensions on request.

Request for a quote

COMERC SP. Z O.O.

Poland

The CMB series hammer mills manufactured by our company are intended to crush and uniform fractions of dry bulk materials with moisture contents of up to 15% and destined for further technological processes. There is option to grind raw materials with higher moisture content, but this parameter has a very significant impact on the device performance. Depending on needs and purpose, CMB series hammer mills cay operate with capacity from 2 t/h to 10 t/h. The raw material is crushed by the impact of the hammers on the raw material and the raw material against the walls of the crushing chamber. The regularity and size of the resulting fraction is determined by the diameter of the holes in the screen used. We recommend collecting the crushed material from under the mill with pneumatic transport, as this enables the use of a pneumatic separator to sift out stones and other impurities that may cause explosions. The use of pneumatic transport will also increase the performance of the mill.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The device is an automatic quantifying, weighing and packaging device. The material is put into weighing box of machine from inlet, when the weight reaches preset amount, the inlet is closed. After the control system receives the signal that bag is prepared, the material is discharged from outlet into the bag. When all the material enters the bag, the control system opens pneumatic valve, transports the bag by the conveyor and brings it to the sewing machine for sewing. Product characteristics: · High efficiency. It adopts three-speed feeding mode with fast, medium and fast speed; · High accuracy with high-precision control instrument, auto-error correction, auto-overfault alarm, and parameter settings backup in power failure; · Wide range of weighing, customized bag-sewing machine with auto package sewing and auto-shearing, innovative optical fiber sensing technology.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The device is an automatic quantifying, weighing and packaging device. The material is put into weighing box of machine from inlet, when the weight reaches preset amount, the inlet is closed. After the control system receives the signal that bag is prepared, the material is discharged from outlet into the bag. When all the material enters the bag, the control system opens pneumatic valve, transports the bag by the conveyor and brings it to the sewing machine for sewing. This machine can pack 450-500 bags of materials per hour, and it reduce the labor cost effectively and packing accuracy control. PRODUCT FEATURES ·High efficiency. It adopts three-speed feeding mode with fast, medium and fast speed; ·High accuracy with high-precision control instrument, auto-error correction, auto-overfault alarm, and parameter settings backup in power failure; ·Wide range of weighing, customized bag-sewing machine with auto package sewing and auto-shearing, innovative optical fiber sensing technology.

Request for a quote

MAYFRAN GMBH

Germany

Mayfran's pneumatic swarf suction system provide for cost-effective collection of scrap from machining operations and transport to a central binning or processing operation. Available in blowing- or suction-based designs, pneumatic swarf transport offer reduced labor costs, improved cleanliness, and significantly increased uptime versus manual swarf removal activities. The systems are flexible enough to meet a wide variety of machine tool arrangements, including innovative at-the-tool design for large gantry-type machine tools.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Double stream mills are used to grind core layer akes or course material rejects from screening processes to ne surface layer akes. In the wood-based materials industry they are the ideal solution when it comes to the further renement of akes. The produced ne akes are used in surface layers for particleboard, for example, in the furniture industry. Surface layer mills are part of a reliable machine technology. In the renement process of akes, which were primarily produced with knife-ring akers type PZKR, these mills produce high-quality surface layer akes Features, Function material feed via vibrating chute heavy-particle and magnetic separator pneumatically supported transport of the ground material inside the machine size reduction between beater plates and grinding segments selectable grinding track geometry interchangeable screens with dierent mesh sizes

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Double stream mills are used to grind core layer flakes or course material rejects from screening processes to fine surface layer flakes. In the wood-based materials industry they are the ideal solution when it comes to the further refinement of flakes. The produced fine flakes are used in surface layers for particleboard, for example, in the furniture industry. Surface layer mills are part of a reliable machine technology. In the refinement process of flakes, which were primarily produced with knife-ring flakers type PZKR, these mills produce high-quality surface layer flakes. Features, Function Material feed via vibrating chute Heavy-particle and magnetic separator Pneumatically supported transport of the ground material inside the machine Size reduction between beater plates and grinding segments Selectable grinding track geometry Interchangeable screens with different mesh sizes Advantages Compact design Separation of heavy particles and ferrous metals Low...

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

Rotary valves have for function the distribution or the continuous dosing of pulverulent products. FORPLEX rotary valves was studied specially to be easily adapted to the base of reception hoppers, cyclones, crushers, pneumatic transport and dust removal captation devices... So they are the essential complement to any installation of grinding, pneumatic transport or classification. Using some size of rotary valves, FORPLEX can provide a solution to meet the most demanding powder properties

Request for a quote

TAMA AERNOVA SRL

Italy

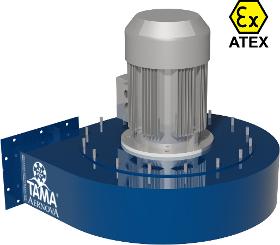

centrifugal ATEX fan used in case of potentially explosive powders The centrifugal ATEX fan generates the necessary depression to enable the extracted air to move through the tubing, filters and machines. It is used in various industrial sectors, both in the ventilation and extractor field, in pneumatic transport, mechanical fume draught and air conditioning. Benefits Its versatility enables its use in a wide range of conditions. Its construction in paint steel sheeting guarantees its durability over time.

Request for a quote

TAMA AERNOVA SRL

Italy

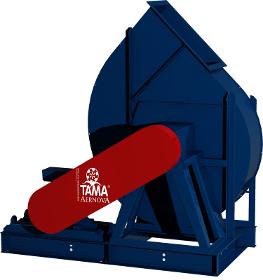

Insulated fan for high temperatures The centrifugal HT fan generates the necessary depression to enable the extracted air to move through the piping, filters and machines. It is used through various industries, both in the ventilation and extraction field, in pneumatic transport. It is suitable for extraction of gaseous streams with elevated temperature. Benefits The fan is completely insulated and it is coated for high temperatures. Standard equipment insulated fan for high temperatures inverter-controlled servo-ventilated motor insulated inspection door high temperature working condition Coating high noise insulation level condensation drain plug

Request for a quote

TAMA AERNOVA SRL

Italy

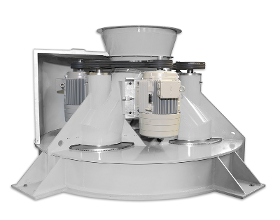

centrifugal fan The centrifugal fan generates the necessary depression to enable the extracted air to move through the tubing, filters and machines. It is used in various industrial sectors, both in the ventilation and extractor field, in pneumatic transport, mechanical fume draught and air conditioning. Benefits Its versatility enables its use in a wide range of conditions. Its construction in paint steel sheeting guarantees its durability over time. It is equipped with IE3 motors in compliance with the EU Directive EuP 2005/32/EC.

Request for a quote

TAMA AERNOVA SRL

Italy

Component to continuously unload the products in granules and powder The rotary valve is a component to continuously unload the granular or powder products from the silos, hoppers, pneumatic transport systems, filters and cyclones. The powder coming from the filter hopper or the auger fall in the unloading outlet of the valve, are moved and then unloaded in the lower part. Benefits The rotary valve was designed according to general and global application criteria. The internal rotor turns to enable continuous unloading of the two different pressure environments. Its constructions is robust and compact, access to the internal mechanical parts are easy and fast. Standard equipment casing, flange and rotor in cast iron gearmotor Optionals available casing, flange and rotor in AISI cast iron harmonious steel blades vulkolan blades chromium casing ATEX version

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pneumatic transport - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Measurement and regulation equipment and instruments - output and flow (3)

- Flour milling - machinery and equipment (2)

- Food canning and preserving - machinery and equipment (1)

- Food industry packaging machinery (1)

- Grinding - machine tools (1)

- Industrial cutting machine tools (1)

- Industrial valves, operating equipment (1)

- Moulding, rubber - machinery (1)

- Packaging recycling (1)

- Wood veneer - machinery and equipment (1)