- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- powder-coating equipment

Results for

Powder-coating equipment - Import export

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Simple and efficient machines, designed for electrostatic powder coating applications with frequently color change within the day. Powder suction is directly from powder coating box that maintains easily fast color change. The equipment is movable, the body consists of a console and a chassis with a vibration table where powder box can be placed. Powder suction is achieved using a conductive pipe that maintains perfect fluidization inside the powder box and a powder injector above it. Powder coating equipment is CE certificated and conforms to the European Norms.

Request for a quote

ERATEC

France

Metal fibre burners for new or existing epoxy powder coating installations Metal fibre burners and infra-red emitters for a more efficient, flexible and compact powder coating installation. POWDER COATING APPLICATIONS Choose the metal fibre burner right from the design stage: Pre/post-treatment, Paint drying, Teflon or ceramic coating, Continuous coating... IMPROVE YOUR FACILITIES The powder coating process: Preparing the substrate: cleaning, pre-heating Application of paint Gelling Polymerisation: hardening paint

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000. When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers. In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System. Oven Tracker Insight Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis.

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Menu: selection of various languages Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment: standard Stud counter (Daily and total counter) Process control Perfectly tuned for weld guns of the SK- and K-series

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfuction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages Two gun connection for stud welding guns

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages Two gun connection for stud welding guns

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

FERPLAST SNC

Italy

CONTAINERS WITH OPENABLE BOTTOM - ONE OPENING - FOR SEPARATE COLLECTION AND INDUSTRIAL WASTE Containers in electro-welded steel, powder coated, equipped with feet. Ideal for use in separate collection of urban, artisanal and industrial waste, for materials such as wood, iron, paper, metal scraps, chipboards etc. The containers can be hooked and lifted by forklift. Waste collection takes place by inserting waste materials from above; while the emptying, for the unloading of the waste, takes place from the bottom, and is accomplished through the actuation of the lever placed on the side of the bin. A cable can be attached to the lever to allow the operator to operate it without having to get off the forklift. The bottom with total opening guarantees a quick and complete unloading of the inserted materials. Since the bins are not hermetically sealed, they are not suitable for inserting waste and residues, soaked in liquids, solvents, oils or the like. The boxes are blue.

Request for a quote

ALUMAX

Greece

Alumax uses its experience, which is based on the realization of a large number of special aluminium products on behalf of large European companies. Our qualified working team will inform you about any possible improvements, which limit the costs and lead to the best productive and qualitative result. Our knowledge in the entire range of activities – definition of quality standards, appropriate materials and equipment, extrusion, powder coating or anodizing, required controls and tests – enable us to design and complete your projects effectively. We emphasize in the critical phases (tooling manufacturing, prototypes production and tests), we monitor closely the production procedures and we can guarantee short lead times. Our aim is the development of a creative and long-lasting cooperation with our customers, by offering products of high quality level, on time and at inexpensive prices.

Request for a quote

SC PROFINOX SRL

Romania

We provide professional powder coating services to achieve a smooth and pleasant finish on your products. The powder coating process ensures efficient and long-lasting surface coverage and costs are considerably optimized. The Profinox team recommends the use of powder coating if you want the surface of your product to have a different look from the one obtained through stainless steel sandblasting or mechanical finishing. You can choose powder coating both for a normal stainless steel painting process, and for elements obtained by laser cutting. The powder coating service performed by Profinox provides you with a high-performance and efficient technique. The process is carried out using a fine powder (a thermoplastic or thermosetting polymer) which is sprayed on and adheres electrostatically to the substrate. After the powder has been evenly distributed, the final step is to fix the paint. This is achieved by exposing the polymers to a temperature of about

Request for a quote

ELEKTRON SP. Z O.O.

Poland

Powder Coating Services by Elektron Group. We provide custom powder coating that gives your projects a bold, long-lasting finish and a protective layer that provides corrosion, oxidation, and damage resistance. We have two furnaces for burning elements with dimensions: • 1650x4400x1900 • 1350x3400x1900 We use a manual applicator to apply Wagner powder paints. Is your question more comprehensive or more general? Send us an email at biuro@web-elektron.pl and we will propose the most suitable solution after its processing.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FOXLASER

Bulgaria

One of the main finishing processes in the manufacturing of products from sheet and profile material is the electrostatic polymer powder coating. The powder coating offered by FoxLaser provides opportunities for painting within the colors of the entire range of RAL and NCS, with their additional effects: gloss, matte, large and fine structure, metallic and others. FoxLaser owns two automated production lines for applying polymer powder coatings. Both of them utilize a five-stage chemical preparation of the parts that guarantees anti-corrosion of at least 504 hours of salt test – and that is without applying zinc primer. We also have the ability to cover the anti-corrosion class C5 (1500 hours of salt test) – one of the highest in the world. We are proud that we can paint large parts with dimensions up to 4000x1700x800 mm.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hardfacing Powders are manufactured to have the precise size, shape, and chemistry required for optimal thermal spraying characteristics. Our powders are available in a wide variety of alloys to give the workpiece desired finished qualities - whether it’s good machinability, abrasion resistance, corrosion resistance, ductility, hardness, or high strength. No matter the application, we have a powder that can be manufactured to your exact specifications and meet your coating needs.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Our company provides design, manufacturing and installation of turn-key customer based.powder coating solutions.

Request for a quote

KSL

Ukraine

KSL provides quality metal powder coating services Powder coating is one of the most popular methods of painting metal products, which uses a special powder consisting of polymer materials and dyes, which is applied to the surface of the object by an electrostatic method or artificial wind. This method allows you to achieve a high quality coating and ensures a long service life of the part. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #powdercoatingservices #powderpaint #lpowdercoatpaint #blackpowdercoat #powdercoating

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hardfacing Powders are manufactured to have the precise size, shape, and chemistry required for optimal thermal spraying characteristics. Our powders are available in a wide variety of alloys to give the workpiece desired finished qualities - whether it’s good machinability, abrasion resistance, corrosion resistance, ductility, hardness, or high strength. No matter the application, we have a powder that can be manufactured to your exact specifications and meet your coating needs. Hardfacing Process Hardfacing or surface coating is a process of spraying or welding metallic powders onto a workpiece or substrate to give it a specific hardness, wear resistance, or corrosion resistance. This process requires the appropriate alloy and particle size distribution for a specific deposition technology. Appropriately selected powders yield the best properties and manufacturing efficiencies.

Request for a quote

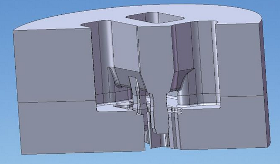

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The powder coating booth is designed for easy and fast color changes during the operation. Different than the conventional powder coating booth systems, it have on it additional systems in order to make the booth fast cleanable. As the most important problem at the conveyorised powder coating systems is color changing time, this powder booth model is the most efficient solution. ADVANTAGES Fast and easy color change; Efficiency 97-98%

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Extra value thanks to energy-efficient powder coatings. Energy-efficient powder coatings are primarily low-temperature powder coatings or fast-reacting powder coatings (NT). Many users of such powder coatings look for the opportunity to lower baking temperatures, thereby achieving direct reductions in oil and gas consumption. However, energy-efficient powder coatings can also increase productivity within the coating system. The baking oven frequently constitutes a bottleneck point in the process. At low baking temperatures, the use of powder coatings can significantly shorten the oven throughput time, thereby increasing the line speed. Take off into the future with new application fields. With energy-efficient powder coatings, you can take advantage of new products and application fields for your company. The range of parts can also be expanded by their usage.

Request for a quoteResults for

Powder-coating equipment - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Coating machinery (3)

- Metal powders (2)

- Anti-corrosion coatings (1)

- Cutting - steels and metals (1)

- Industrial containers (1)

- Industrial paintings (1)

- Infrared tubes (1)

- Metalworking hand tools, non-power (1)

- Painting machinery and equipment (1)

- Paints and varnishes (1)

- Plastic coating - steels and metals (1)

- Turbine drilling services (1)