- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recycling machinery

Results for

Recycling machinery - Import export

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our machinery enables great flexibility at constantly high throughput to recycle your plastic waste efficiently and recourse-saving with help of different recycling processes Currently we run two modular recycling lines for clean, single-polymer and thermoplastic waste. One shredding-grinding line for up to 6.000 tons yearly and one modular shredding-grinding-agglomeration line for up to 9.000 tons which enables parallel or in-line grinding and agglomeration. With those two lines we can process any plastic waste the optimal, resource-efficient way. Since the foundation in 1997 we have developed a deep process knowledge for many types of plastic waste, to produce non-cloggy, free-flowing and dry regrind and agglomerate. After every polymer change our recycling lines are cleaned meticulously to avoid contamination from a polymer-mix. All metal parts are detected by metal detection and the recyclate runs through a dedusting machine before being filled into big bags.

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our recylcing machinery can process multiple types of thermoplastic polymers in diverse forms. Important is that the waste is clean, contains one polymer only and is thermoplastic. Our largest polymer is PVC. About 60% of the processed plastic waste is rigid or soft PVC. The reaming 30% are mainly PP and HDPE but also LDPE and multiple engineering grade polymers. The plastic waste can be mixed or single-colour (black, white, grey etc.). We buy plastic scrap of the following polymers: We can process many different types of plastic waste independent of form or size. Our recycling machinery enables a flexible recycling of solid, thin-walled and powdery plastic waste.

Request for a quote

MIXT SP ZOO

Poland

PET bottle flakes recycling system Top one in recycling field CE certificated Automatical Machine Description This PET Bottle recycling line is used for crushing, washing and drying the PET and PVC bottles. Plastic Recycling Machine//Plastic recycling machinery/Pet bottle recycling line/Pet recycling plant/Pet washing plant/Pet washing line/Plastic washing machine/Pet bottle washing line/Pet bottle washing machine/Pet bottle recycling equipment/ ` A. Features and application: 1. PET Bottle washing line is used to crush, wash, dewater and dry PET and PVC Bottles. 2. It takes the advantages of simple structure, easy operation, high capacity, low energy consumption, safety, reliability, etc. 3. The Crusher and Label remover are the most important parts in this line, if you want to know more, welcome you to contact us by telephone or emails, we will provide you the detailed

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Track Mounted Mobile Washing and Screening System? Track-mounted mobile screening and washing units are adaptable and productive pieces of machinery used in recycling mining and aggregate production. A vast variety of materials including aggregates ores coal and industrial minerals can be screened cleaned dewatered and classified using these units. The mobility of track-mounted mobile screening and washing units is a significant benefit as it facilitates their easy transportation to various job sites. This adaptability lowers the need for multiple machines at different locations while increasing productivity. Furthermore these units are outfitted with cutting-edge features like hydrocyclones vibrating screens and water treatment systems to guarantee peak performance and superior quality of the finished product. All things considered mobile screening and washing-track mounted units which offer effective and affordable solutions for screening and washing operations

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Track Mounted Mobile Washing and Screening System? Track-mounted mobile screening and washing units are adaptable and productive pieces of machinery used in recycling mining and aggregate production. A vast variety of materials including aggregates ores coal and industrial minerals can be screened cleaned dewatered and classified using these units. The mobility of track-mounted mobile screening and washing units is a significant benefit as it facilitates their easy transportation to various job sites. This adaptability lowers the need for multiple machines at different locations while increasing productivity. Furthermore these units are outfitted with cutting-edge features like hydrocyclones vibrating screens and water treatment systems to guarantee peak performance and superior quality of the finished product.

Request for a quote

OMECHA UAB

Lithuania

Vertical chain mill. For recycling materials: plastics, straw, organic waste, aluminum, metal, WEEE scrap and sheet metal parts. Reliable separation of material fractions and environmentally sensitive components. Batch milling controls the size of the material by adjusting the grinding time

Request for a quote

OMECHA UAB

Lithuania

Ball mills for crushing, and separating bulk materials. Batch milling controls the size of the material by adjusting the grinding time. The ball mill uses steel balls as grinding media. The ball mill can efficiently grind various materials into fine particles.

Request for a quote

ODAV PRINT OÜ

Estonia

Samsung ML 2160, Samsung ML 2162, Samsung ML 2165, Samsung ML 2165w, Samsung ML 2168, Samsung ML 2168w, Samsung SCX 3400, Samsung SCX 3405fw, Samsung SCX 3405w, Samsung SCX 3405, Samsung SCX 3505 W, Samsung SF760 P, Samsung SF760p, SCX3405

Request for a quote

ODAV PRINT OÜ

Estonia

Brother DCP-L2510D, Brother DCP-L2530DW, Brother HL-L2310D, Brother HL-L2350DW, Brother HL-L2370DN, Brother HL-L2370DW, Brother HL-L2370DW XL, Brother HL-L2375DW, Brother DCP-L2550DN, Brother MFC-L2710DN, Brother MFC-L2710DW, Brother MFC-L2730DW, Brother MFC-L2750DW

Request for a quote

ODAV PRINT OÜ

Estonia

Brother DCP-1510, Brother DCP-1512, Brother DCP-1610W, Brother DCP-1612W, Brother DCP-1612WVB, Brother HL-1110, Brother HL-1112, Brother HL-1112A, Brother HL-1210W, Brother HL-1212W, Brother HL-1212WVB, Brother MFC-1810, Brother MFC-1910, Brother MFC-1910W, Brother DCP-1610

Request for a quote

ODAV PRINT OÜ

Estonia

HP LaserJet Pro M15, HP LaserJet Pro M15a, HP LaserJet Pro M15w t, HP LaserJet Pro MFP M28a, HP LaserJet Pro MFP M28w, M14, M17, HP LaserJet Pro MFP M28-M31, HP LaserJet Pro M14-M17

Request for a quote

ODAV PRINT OÜ

Estonia

HP Laser 107a HP Laser 107w HP Laser MFP 135a HP Laser MFP 135w HP Laser MFP 137fnw

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We offer standard EPS recycling machines and equipment with good quality and competitive prices. Our range of EPS recycling machinery is as follows: * EPS crusher and grinder * EPS deduster - dust collection unit with scrap silo and dust filters * EPS scrap mixing unit with scrap and fresh material silos * EPS scrap silo (half fabric, half metal or fully metal) * Options for material transfer and handling system with or without automation For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnets for recycling separate ferrous and non ferrous metals from waste streams or bulk streams. For the elimination of impurities from raw materials or recovery of valuable metals from product streams. An overband magnet effectively and quickly separates high volumes of iron or steel and hangs above a flat or trough-shaped conveyor belt. This type of magnet is self-cleaning and continuously draws Ferro parts from a material flow. he iron removal efficiency of overband magnets ranges from 70 to 90%. This depends on magnet design, product flow and placement. We also manufacture Eddy current separators which remove non-ferrous metal particles, such as copper and aluminium, in a continuous process. For the recovery, recycling or removal of metals.

Request for a quote

WRIGHTS RECYCLING MACHINERY LTD

United Kingdom

This separation system is a totally new concept in granulated cable separation. Wrights Recycling Machinery’s cable separating systems will produce up to 99% clean copper and up to 99% clean plastic. This is a wet separation system with an optional dryer available. It can be manufactured in different sizes to process anything from 200kg –1000kg per hour. These systems can be manufactured to your requirements.

Request for a quote

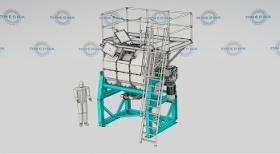

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For optimal waste recycling for our clients, Bezner engineers and builds waste management and recycling machinery according to customer’s recycling and sorting goals, dimensions and budget. We build both conventional components and ingeniously tailored units. Specific equipment outside our range from secondary suppliers can be included. This way, our project management team offers a turnkey solution.

Request for a quote

MIZAR RECYCLING MACHINES LTD.STI.

Turkey

Motor: 90 kw Blade Nr: 60+4 Length:6.200 mm Width: 2.100 mm Height: 3.700 mm Weight: 6.800 kg Capacity: 1.000 - 1.500 kg Electric Components: Siemens Hydraulic Components: Bosch Rexroth

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIZAR RECYCLING MACHINES LTD.STI.

Turkey

Motor: 55 kw Blade Nr: 40+4 Length:5.300 mm Width: 2.000 mm Height: 3.600 mm Weight: 5.000 kg Capacity: 750 - 1.000 kg Electric Components: Siemens Hydraulic Components: Bosch Rexroth

Request for a quote

B+B ANLAGENBAU GMBH

Germany

For recycling plants worldwide, we design, supply, install, and maintain plastic recycling machinery and complete washing lines for nearly all kinds of plastic. Besides supplying standard units, we offer custom-made machines, full installations, spare parts, and maintenance support.

Request for a quoteResults for

Recycling machinery - Import exportNumber of results

20 ProductsCountries

Category

- Printing - supplies (5)

- Recycling - machines and installations (4)

- Copper wires and cables (3)

- Industrial design (2)

- Plastics - industrial raw materials (2)

- Concrete preparing - machinery and equipment (1)

- Flat screens (1)

- Granulation, plastics - machinery (1)

- Magnetic equipment (1)

- Packaging recycling (1)

- Scrap iron - salvaging and recycling (1)

- Waste treatment and recycling - machines and installations (1)