- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recycling screening machines

Results for

Recycling screening machines - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Aluminum separators automatically pick up aluminum and steel cans from all waste collected from the recycling stations. 1. Recovery aluminum cans from plastic bottles. 2. High efficiency of recovery of aluminum from city waste.

Request for a quote

TECHNIC MACHINES

Turkey

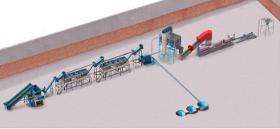

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

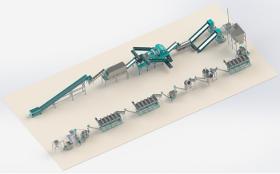

Our PET bottle recycle machine line is designed to give great recycling solution for PET bottle recycle process. We provide different solutions according to our customers PET bottle recycle machine demand, such as different capacity, dirtiness level, hot washing or cold washing system or etc. So we design our PET bottle recycle machine according to our customer's market requirements. Our PET bottle washing line can be designed for high level dirty PET bottles, with or without bales, Hot-Wash or Cold-Wash and etc. PET Bottles Recylce Machine Line Main Units, – Conveyor – Bale Opening Machine – Helezon – Cap and Label Remover – Sorting Belt – Drum Tromel – Conveyor Belt – Crusher Machine – Screw Loaders – Hot Washing Unit – Friction Washer – Flotation Tanks – Drying Units – Big Bag Filling Unit Just contact with us for your PET bottle recycling machine research, we will provide the optimum solution.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

There are many techniques to separate waste. Bezner has developed screening machines for the recycling industry with linear, circular, rotating, and elliptical (ballistic) sieving motions. We offer in-house engineering and manufacturing of screening machinery.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANHUI HENNING SAINT TECHNOLOGY CO., LTD.

South Africa

Henning Saint plastic color sorter, as an intelligent machine, It is suitable for sorting different colors of PET bottle flakes, PE bottle cap flakes, HDPE milk bottle flakes, ABS and PS waste electrical flakes and other plastic recycling flakes and granules. We use a double-layer track design that allows for random switching between accepts and rejects re-sorting, plus dual vision cameras for higher sorting performance. Henning Saint plastic color sorter always provides customers with intelligent, professional and comprehensive sorting solutions. Equipped with innovative online detection technology to enhance customers' after-sales service experience.

Request for a quote

ANHUI HENNING SAINT TECHNOLOGY CO., LTD.

South Africa

The Henning Saint color sorter for waste glass can quickly sort out foreign matter such as stones from waste glass and remove miscellaneous colored glass. It can also sort the colored glass to improve the value of your recycled glass cullets.

Request for a quote

PRODEV ENGINEERING

Turkey

Inclined screens are very important for all mineral processes. The process of grouping the bulk material containing pieces of different sizes in at least two size ranges is called screening. The screening process is referred to as the "classification process" in mineral processes. Screening panels with specific sizes of mesh are attached to the screen body. While the fed material moves on the screen panel with the vibration of the body, the pieces smaller than the mesh gap pass to a lower screen panel with a smaller mesh size to be screened again.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The MRS extruder processes undried PET bottle flake without any pre-treatment directly into pellets. The polymer melt is intensively and rapidly exchanged in the multiple screw section of the extruder. The huge surface area is exchanged at an unparalleled rate so that even with a moderate vacuum level of 25 to 40 mbar in the degassing section, contaminants are efficiently evaporated out of the melt. A letter of Non Objection (LNO) from the FDA underlines the decontamination efficiency. If, in order to boost the intrinsic viscosity (IV) a downstream solid state polymerisation system (SSP) is used, this can be specified far shorter than otherwise necessary as the extruder has already carried out the decontamination of the bottle flakes. The end product is of especially high quality with regard to transparency and yellowness.

Request for a quoteResults for

Recycling screening machines - Import exportNumber of results

10 ProductsCompany type