- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rollers for conveyor belts

Results for

Rollers for conveyor belts - Import export

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

NOVELTY STEEL

Turkey

While various idlers have been developed to perform adequately in different installations, determining the most appropriate one remains a challenging task. The primary function of an idler roll is to provide load support with minimal resistance to movement, particularly addressing radial loading from the belt and materials across specific idler spacing. This role encompasses absorbing impact at the loading point and managing belt tension in curved sections, which can be challenging to quantify. Modern conveyor design methods have enhanced our comprehension and control, providing clearer insights into idler implications. Assemblies of idler rolls are strategically designed to influence the belt profile, often forming a trough or tube. It’s essential to acknowledge that the trough’s shape, consistency, and flexibility significantly impact idler roll behaviour.

Request for a quote

BIZERBA SE & CO. KG

Germany

For the formation of pre-defined package units downstream of a Bizerba labeling system The fully automatic TU 100 unit maker consists of an electrically driven, two-part package removal station with an electro-pneumatic diverter arm. It makes units according to predefined criteria, optimizing the packing process and the control of sum labels for the packages. Up to 100 packages per minute are possible. The TU 100 can be optionally fitted with a roller conveyor or a belt conveyor. (optional)

Request for a quote

FERPLAST SNC

Italy

WEIGHING BARS FPPMB SERIES - INDICATOR EXCLUDED Pair of weighing bars suitable for weighing boxes or pallets such as hoppers, conveyor belts, roller conveyors, tanks, crates, etc. They can be applied in packaging lines for weighing boxes and pallets pre-filled with material. CE-M verifiable standard version for sale to third parties. TECHNICAL FEATURES - Functioning with 4 shear-beam approved IP68 stainless steel load cells (PMBL) and with 2 approved off-center aluminum load cells (PMBS-PMBM-PMBX), according to OIML R60 standards with protection against dust and humidity according to IP65 standards (350 Ohm input resistance). The price indicated refers only to weighing bars. The photos are purely indicative and show the various applications of the bars (*) CE-M divisions obtainable only with the relative options, combined with our indicators.

Request for a quote

PSAPLAST - PLÁSTICOS SANTO ANTÓNIO, LDA.

Portugal

When empty they nest in each other to reduce the volume. Stacks by turning 180º Produced on request for a minimum order quantity of: 6x130 = 780 units. Includes a recessed area on each of the 4 walls to ensure barcode labels are not damaged when nesting or de-nesting the boxes. Optionally, barcode labels can be equipped with a chip for radio frequency identification. Designed with a base reinforced with ribs inside of the box, to ensure that when stacked with considerable weight (for example, with books) the base does not gain a deflection that could prevent the boxes from moving on inclined roller planes. The underside of the base is smooth to ensure noiseless sliding on roller planes, or movement on conveyor belts without wearing them out.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

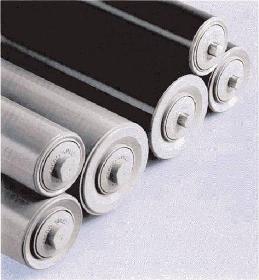

Due to the characteristics of the materials of which they are made, these rollers are used in conveyors operating in highly corrosive environmental conditions.With a state-of-the-art manufacture, they possess the requisites of the specifications for steel rollers on page 4. Operating temperature: 10 ÷ +50 [°C].

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Steel clamped or monobloc rollers mounted on pre-lubricated and protected radial ball bearings.The externally threaded shaft protrudes from only one end of the tube.In belt conveyors, they are vertically mounted in pairs at the edges of the rubber matting, with the function of restricting any lateral slipping. They are installed on self-centring stations with the same function.The technical characteristics of Series 6 rollers are those of the relative base rollers.Other finishes, see page 30.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

They consist of two steel clamped or monobloc rollers mounted on a single “V”-folded shaft. They have the upper bearing mounting heads with hermetic closure and the lower ones, with protruding shaft, with labyrinth dust protection. The shaft is locked in the housing of the central bracket.The latter, with a base plate fitted with mounting holes, is made of cold-formed steel sheet.They are used in concave belt conveyors that operate, even in bad environmental conditions, at medium-high speed, with medium loads and sizes.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

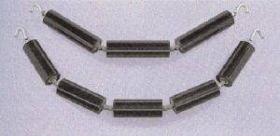

Garland roller sets are used in belt conveyors that have to handle blunt, bulky, heavy materials. The increased containment capacity of the roller basin facilitates higher speed of transport than those of traditional stations. For upper stations in current use installations, garland sets with 3 and 5 steel or rubberised impact rollers are mounted; for lower stations, garland sets with 2 steel rollers or with scraping rubber rings are mounted. The flexibility of garland sets enables their adaptation to the material to be transported, facilitates transportation, reduces impacts on the rollers, and limits any lateral slipping of the rubber matting. The diagrams and Table 90 show the shapes of mountings of garland sets envisaged in TECNORULLI’s production programme. Other shapes may be considered on request.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

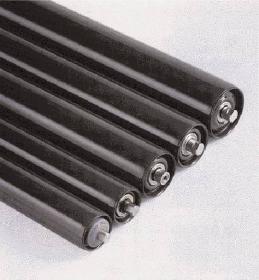

Steel rollers with jacket consisting of tube and bearing mounting head rigidly coupled by welding. They are mounted on pre-lubricated angular or radial ball bearings and protected with double labyrinth, triple labyrinth dust seals with additional watertight protection. Monobloc steel rollers are used in belt conveyors with medium, heavy or very heavy loads. The diagrams and tables on page 42 show the dimensional characteristics and maximum loads.Operating temperature:-10 ÷ +90 [°C].

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Steel rollers with jacket consisting of tube and bearing mounting head rigidly coupled by pressure. They are mounted on pre-lubricated angular or radial ball bearings protected with double-labyrinth dust seals. Clamped steel rollers are used in belt conveyors with limited or medium-heavy loads. The diagrams and tables on page 34 show the dimensional characteristics and maximum loads. Operating temperature:-10 ÷ +90 [°C].

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Garland roller sets are used in belt conveyors that have to handle blunt, bulky, heavy materials. The increased containment capacity of the roller basin facilitates higher speed of transport than those of traditional stations. For upper stations in current use installations, garland sets with 3 and 5 rubberised impact rollers are mounted; for lower stations, garland sets with 2 rollers with scraping rubber rings are mounted.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Due to the structural characteristics of the materials of which they are made, these rollers are used in belt conveyors in handling systems of bulk materials, including sharp and abrasive, mixed size, large and heavy materials, in normal, dusty and aggressive environments. As upper rollers, their field of application is specifically in the loading areas of conveyors to protect the rubber matting from the dynamic action of falling materials. They consist of monobloc base rollers with steel tube and special anti-abrasive rubber rings pressure-aligned on the jacket.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Due to the structural characteristics of the materials of which they are made, these rollers are used in belt conveyors in handling systems for bulk, humid or sticky materials, in normal, aggressive environments; operating temperature also low. As lower rollers (return) because they prevent the accumulation of material carried by the band, the field of application is specifically on the steel tubes; they thus favour linear and jolt-free running of the rubber matting. They consist of clamped or monobloc base rollers with steel tube and special anti-abrasive rubber rings pressure-aligned on the jacket.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

We consider your process as a whole and plan the conveyor technology for the entire facility together with you. In addition to all mechanical and electrical engineering, we provide complete mechanical and electrical manufacturing with assembly service. From chain conveyors, telescopic conveyors, roller conveyors to belt conveyors and fully customized conveying systems, we supply you with everything from a single source

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

High performance with the new DAMBACH conveyor modules for totes, cartons and trays. With decentralized conveying functions and standardized modules, a wide range of material flows can be mapped easily and quickly. All modules are perfectly matched and can be freely combined. Also thanks to the high level of standardization of individual assemblies. This not only increases flexibility, but also reduces spare parts inventories. The comprehensive container conveyor technology modular system consisting of roller cams, lift converters, infeed and discharge conveyors, accumulating roller conveyors, belt conveyors, lifters and leaves nothing to be desired. Our sales department supports you from the planning phase through layout design to implementation. The robust design with integrated cable ducts and sensors ensures maximum functional reliability. Motor rollers and side guides are easily accessible without time-consuming disassembly of the cover.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has enjoyed renown for belt conveyor hooded covers made of metal for many years. We have decisively extended our product range with the sale and distribution of plastic cover hoods. Due to statutory requirements, different sectors of industry require alternatives to the metal systems. In particular, the industries of food, sugar, chemicals, potash and salt are reliant on hooded covers made of Organit plastic. The corrosion resistant hoods reliably protect conveyor belt, roller bearings and the material conveyed against the weather. They can be easily removed at any location so that the conveyor belt can be inspected and then replaced. Organit conveyor belt hooded covers made of rigid PVC, transparent and natural, in sheeting pile 70/18 have the following features hardly inflammable DIN standard 4102 impact resistant DIN standard 7748 chemically stable DIN standard 16929 maintenance free low weight easy handling

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KESTASMAK MINING MACHINERY AND SPARE PARTS

Turkey

jaw crushers, primary impact crushers, secondary impact crushers, dewatering systems, screens, vertical shaft impact crushers, VSI, VSI spare parts, crusher wearing parts, feeders, bunkers, conveyor systems, conveyor belts, conveyor rollers, conveyor drums, belts, clamps, high carbon steel woven meshes, anti clogging, anti-clogging screen meshes, flex screens, perforated steel screens, bolts, polyurethane screens, polyurethane tensioned screen panels, polyurethane jig screens, polyurethane dewatering screens

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

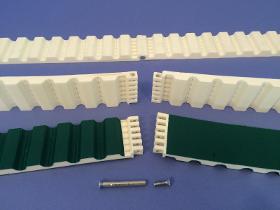

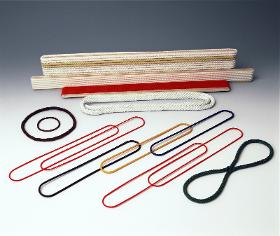

PU timing belts with easy joint as strong as a welded joint The easy joint timing belt fastener is the perfect solution, for a quick and easy mechanical endless connection of PU timing belts. Assemble without disassembling, without stopping your production line Replace your belts in few minutes without disassemble your hoods, pulleys, axis. Reduce your production downtimes. The method of mechanical assembly and fastening system easy joint offers unique solutions for easy and fast repairs of power transmission belts or conveyor belts. Pitches: H / T10 / AT10 / T20 / AT20 / 8M / 14M Standard: Polyurethane 90° Shore A grey Versions: Standard, PAZ, PAR Cords: reinforced with a Polymercord around the Pin in each tooth joint, arranged in parallel Width: from 10 to 150mm, (wide belts possible on request)

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Our endless turned round belts are wound either out of one homogeneous strand or one cord and spliced endlessly without thickening. For special applications, it is possible to vulcanize the inner splice or to make a special splice based on our in-house engineering methods. This increases the tensile strength by up to 60%. In elastic types, the core is welded. In view of their special structure, twisted round belts exhibit very quiet running properties, are extremely flexible and, thus, make possible very small minimum pulley diameters of 3x belt diameter. For several types, speed up to 70,000 rpm is possible; however, the speed of 60m/s should not be exceeded. Elastic types: PU, Vulkollan Semi-elastic types: PA.6, Set-Polyester, Nylon, HE Types with limited extensibility: Polyester, Nomex, Nomex-PTFE, Polyester-PTFE, Kevlar/Twaron, PA.6 anti-static, PBO

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Endless extruded round belts Our endless extruded round belts are ideal for low power requirements. They are elastic power transmission elements that do not need cost-intensive tensioning devices. In view of the special production process, they do not have any welding seams or terminal connections and run very smoothly. Moreover, they allow a minimum pulley diameter starting from 5.5 x belt diameter. Our types E80, V75, C70 and P82 are made of specially selected and dynamically tough materials. In addition, type E80 also is antistatic to a limited extent and has a resistance value of about 106 Ohm; thus, it is excellent for use in electronic devices and chip production. Available diameters: 1.8mm - 7mm Available lengths: 40mm – 1,610mm Temperature resistance: -20°C - +160°C Coefficient of friction: 0.35µ - 0.9µ* Maximum tension: >100N

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Round hook belts are the ideal solution for power transmission or conveying systems where several belts run on one shaft. Since they are easy to install, downtimes and maintenance costs can be reduced significantly. The hook belts only have to be inserted. Then the belt is joined to the hook and the second side of the hook is closed with pliers. Thus, there is no time-consuming and cost-intensive assembly work.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

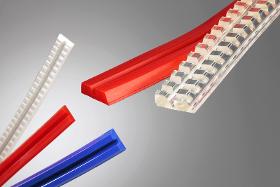

PU V-belts run individually or alongside one another and convey products on slightly ascending or descending conveying systems without allowing the products being transported, e.g. boxes, tiles, glass slabs, cardboard articles etc., to slip. In addition, PU V-belts are used for driving live roller conveyors. Standard stock program: 75° Sh.A red 80° Sh.A transparent, FDA 80° Sh.A sky-blue, FDA 85° Sh.A green 90° Sh.A white Profiles 6x4 / 8x5 / 10x6 / 13x8 / 17x11 / 22x14 Smooth or notched

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Hollow core belts for nipple connections when quick and easy installation is needed. Standard stock program: 75° Sh.A red, smooth 80° Sh.A sky-blue, smooth, FDA 85° Sh.A green, smooth Available diameters: 4.8mm - 15mm Available lengths: starting from 110mm Available hardness: 75° Sh.A – 85° Sh.D Temperature resistance: -30°C - +70°C Coefficient of friction: 0.3µ - 0.7µ

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

We have a complete range of polyurethane round belts for conveying and power transmission applications. PU round belts, extruded in open lengths, are homogeneous round profiles that can be welded for use as high-quality power transmission and conveying elements. Our stock mainly comprises solid profiles with a smooth or slightly roughened surface and hollow profiles for nipple connections. Several types have FDA/USDA approval and comply with EU Directive 2007/19/EC. Although we generally produce in open lengths, we can also produce all belts according to your specifications. Our round belts convey a wide range of products such as foodstuffs, glass, roof tiles, PC boards and many more. The standard range of round belts is rounded off with aramid, polyester or glass-fiber reinforcements. If an appropriate quantity is purchased, we also produce special types with PES or aramid reinforcements.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Polyester felt belt antistatic

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Polyester felt belt antistatic

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Polyester felt belt antistatic

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PVC conveyor belt 2-ply black with felt top

Request for a quoteResults for

Rollers for conveyor belts - Import exportNumber of results

155 ProductsCountries

Company type

Category

- Conveyor belts (145)

- Bearings - ball, needle and roller (9)

- Grids, gratings and wire mesh (8)

- Conveyor systems (7)

- Mining and quarrying - machinery and equipment (2)

- Turning - steels and metals (2)

- Biscuits (1)

- Boxes and trays, storage (1)

- Food industry - machinery and equipment (1)

- Rubber products (1)

- Steel, crude (1)

- Steels and metals - forming and cutting (1)

- Storage equipment and systems (1)

- Weighing and dosing equipment (1)

- Welding, electric - equipment and supplies (1)