- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sealed cups

Results for

Sealed cups - Import export

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

SYNERLINK

France

Our DN250 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed of 18,700 to 43,200 cups per hour. Our machine can handle various materials (PS, PET, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SYNERLINK

France

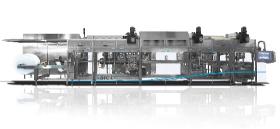

Our AR700 cup thermoforming machine is known for its user friendliness, great reliability, simple design and layout. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Its high adaptability to changing market needs and easy operation and maintenance are ideal for high speed production lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 57,600 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical, straight and open mold cups with or without label.

Request for a quote

SYNERLINK

France

Our DP300 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. This machine versatility and technical efficiency are ideal for medium lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 28,800 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

KULLEN-KOTI GMBH

Germany

We offer you the following selection criterias: - All fill materials possible, e.g. natural bristles and hair, plant fibres and synthetic filaments. - As backing material we use galvanised steel and stainless steel (1.4301, 1.4571) tapes. - The same possibilities are available for the production of strip brushes in arch form however not only in semi circles but also in other pitch forms. The larger the dimensions the better multiple brush segments can be mounted around the perimeter. Besides the cup form the strip brush can be bent in any other form.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The MANOY® U‑Cup is a pressureactivated sealing system. This means that the total sealing force is only ever as high as required to seal the prevailing pressure. This friction optimization saves energy.The MANOY® U‑Cup seals gases and liquids and also highviscosity fluids and pastes in a nonstandard version

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The MANOY® U‑Cup is a pressureactivated sealing system. This means that the total sealing force is only ever as high as required to seal the prevailing pressure. This friction optimization saves energy. The MANOY® U‑Cup seals gases and liquids and also highviscosity fluids and pastes in a nonstandard version

Request for a quote

KUZEY GLOBAL

Turkey

Rounds moulds have a wide variety of applications in food and beverages industry. Parties, restaurants, take-away service stations, hospitals, canteens, offices, outdoor events etc. Usta-Form provides moulds for all kinds of round cups , food containers for food and beverages industry. From our European material used moulds, you can easily produce lightweight, durable cups from PP, PS, PET and these can be used for storing liquids and food, where the products are mostly food-grade and leak-proof. Round yogurt cups Tea and coffee cups Water cups, filled and sealed or with no sealing Dairy cups Ice-cream cups Yogurt bowls Hummus bowls Soup bowls Salat containers Rectangular Moulds We manufacture accurate and strong moulds for rectangular containers, trays, lunch boxes, take-away containers that are used in catering, supermarkets, restaurants, canteens, hospitals and many more other fields that require disposable plastic cups and containers from PP, PS, PET.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Abrasion resistance/Zirconia ceramic ring for sealed ink cup/pad printing/innovacera 1. Introduction: Round Zirconia ceramic ring is used for a Ever Bright pad printing ink cup machine, electronic control, lighting and electrical temperature control and other industries.Zirconia ceramic scraper ring is also used for thermostat,technical ceramic,temperature control. The temperature controllers,manufactured with Zirconia,have revolutionary breakthrough if compared with traditional plastic parts.They are highly improved in strength,insulation performance,heat resistant performance,especially sensitivity to temperature Innovacera is offered Yttria Tetragonal Zirconia Polycrystal(Y-TZP), there are many applications of Zirconia ceramics in the chemical and petrochemical industries. They provide economic payback in the way of reduced maintenance and down time. Zirconia ceramics is also becoming the material of choice for components in healthcare applications.

Request for a quote

FOOD PARTNERS CO

Belgium

BUBBLE TEA is an original and refreshing drink made of green tea or black tea, fruity syrup and small pearls (called bobas) with various flavors and colors that burst in the mouth! To be enjoyed cold, in a hermetically sealed 450 ml cup and with a large diameter straw to absorb all the bobas! Bubble Tea is declaned in severa flavours and the product shelf life of 14 days after production allowing for distribution throughout Europe, whilst ensuring a shelf life in store of at least 10days. Contact us for a quote or to discuss about your project

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The desiccant pouch packing machine automatically measure the desiccant via the cup or weigher according to your setting parameter in touch screen, packing machine will form the roll nonwoven fabric to be a sachet according to your design, normally it’s pillow pouch,side sealing pouch, stick bag . Then cup or weigher will filling the measured desiccant into the formed sachet and sealing with ultrasonic cold sealing model which is suitable for nonwoven fabric .You can add feeder instead of manually add self hot powder into weigher , add ink printer so print the lot number or LOGO on the sachet , add end weigher checker so it will detect the sachet which weight is beyoud your accept tolerance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The activated carbon and fertilizer granule pouch packing machine automatically measure the activated carbon and fertilizer via the cup or weigher according to your setting parameter in touch screen, packing machine will form the roll nonwoven fabric to be a sachet according to your design, normally it’s pillow pouch,side sealing pouch, stick bag . Then cup or weigher will filling the measured activated carbon and fertilizer into the formed sachet and sealing with ultrasonic cold sealing model which is suitable for nonwoven fabric .You can add feeder instead of manually add activated carbon and fertilizer granule into weigher , add ink printer so print the lot number or LOGO on the sachet , add end weigher checker so it will detect the sachet which weight is beyoud your accept tolerance. Machine is able to sealing with 2 layer nonwoven fabric for some special products.

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

A single-acting rod seal, Zurcon® L-Cup® is an alternative to the U-Cup. It is a highly effective sealing system offering optimized sealing performance and extended service life. With exceptionally low friction properties, it has high wear resistance, back pumping ability along with high static and dynamic tightness.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

TAMPOPRINT GMBH

Germany

With the SEALED INK CUP series you will receive a modern and technologically high-quality electropneumatic pad printing machine. The ideal starter model for stand-alone use. The SEALED INK CUP can be connected to transfer systems or components of your automated system. Thanks to a 37-pole automation interface (standard equipment), it is now prepared for the design enhancement with optional features. Its control is easy to operate. The SEALED INK CUP series shows an internationally convincing price-performance ratio ”Made in Germany”.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NHM LIMITED

Ukraine

TECHNICAL SPECIFICATIONS: Product to be packed: Yogurt, Lala, Sour Cream, Mayonnaise, Mustard Paste, Honey Dosing volume: 150-500 ml Speed, max.: 55-60 cups/min Cup material: Plastic cups Lid material: Aluminum Voltage: 220 V, 50 Hz Power: 2 kW Compressed air, max.: 900 litres/min. at 6 bar Dimensions: 2400 x 1200 x 1900 mm Programmable Logic Controller: Unitronics (Israel) BASIC SCOPE OF SUPPLY: Entire frame & guards of the machine is made of stainless steel SS304 with protective acrylic covers and door handles Parts which are in contact with product made of stainless steel SS316 Drive unit for cup & lid-holder disc (there are pins around the cavity on rotary turret to hold the lids. The cups magazine has a step to hold the cups during discharge) Piston filler for viscous products Cup feeder to turret with vacuum cup Magazine for top aluminum lid loading & lidding unit (precut lids) Lid sealing device “NO cup – NO filling” system Inkjet printer for date coding

Request for a quote

TAMPOPRINT GMBH

Germany

The ergonomic guiding idea for the MODULE ONE series was to develop a machine that is easy to operate and whose processes are immediately visually apparent. In addition, it should be simple, safe, and user-friendly. The MODULE ONE series consists of 4 different models: MODULE ONE M and MODULE ONE S are semi-automated machines. MODULE ONE XS and MODULE ONE XXS are manual workstation solutions. Pad printing machines of the HERMETIC, SEALED INK CUP and V-DUO series are available for placement of the MODULE ONE series. With the MODULE ONE series, up to 1200 parts/h can be printed with up to two or three colors in high precision. With a print image in up to three colors, the series is suitable for decorating and labeling a wide variety of printed goods such as toys, figures, model vehicles, etc., but also for marking technical devices and components.

Request for a quote

FALCONTEC LTD

United Kingdom

Choice of 0.457mm or 10.00mm thick cliché plates. Suitable for use on both open and sealed cup pad-printing machines. Advantages of using 0.457mm thin pad printing plates * Less dependent on a clean air environment, considerably more durable and less easily damaged than softer photopolymer plates. * Have accurately controlled etch depths adjusted to suit all requirements * Hard wearing and more resistant to scratching than photopolymer plates * Can be effectively screened * Can be punched with holes to accommodate pin registration requirements ** Click to know more **

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Properties: Filling with gross weighing system Capacity of up to 250 containers/min. Fills metal cans Low space requirement, integration solution for monoblock with a sealing machine Filling process with cup dosing machine Maximum accuracy thanks to precisely manufactured fill heads Rotating carrier segments Vibration over the entire transport area beneath the funnels Mean value controller Max./Min. jam detection Recognition of container top/bottom Gas Flushing “No jar no fill” system Options: Installation of an Optima extraction system for product extraction <1%

Results for

Sealed cups - Import exportNumber of results

22 ProductsCompany type

Category

- Food Industry - Machines & Equipment (4)

- Packing and packaging - machinery and equipment (4)

- Food industry - machinery and equipment (3)

- Pad printing (3)

- Automation - systems and equipment (2)

- Sealing rings (2)

- Beverages - import-export (1)

- Ceramics, industrial (1)

- Food industry packaging machinery (1)

- Metal engraving - machine tools (1)

- Seals (1)