- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punching machines

Results for

Punching machines - Import export

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

MECANIC SYSTEMS SA

Belgium

With the acquisition in June 2011 of the Fiber Laser we have the possibility to work in combined mode as if we had a combination machine: punching takes place on the 5000R and laser cutting on the Fiber Laser after a very accurate optical calibration. This technology allows to get the best of both worlds: simple shapes are cut at optimal speed on the punching machine whereas more complex shapes are cut with the Fibre laser after optical calibration. It is also possible to perform thread forming and dimpling (form countersinking). The accuracy of these machine is 0.1 mm for metal sheets up to 3000x1500mm. They are equipped with an automatic loader and unloader.

Request for a quote

FRIMO GROUP GMBH

Germany

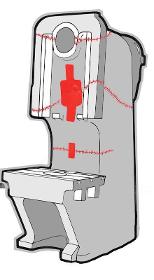

A compact and ergonomic punching machine for high volume production The FRIMO ErgoCut is an extremely compact and ergonomically designed punching machine very well suited for trimming complex and large components in high volume. This includes instrument panels, door panels, center consoles and armrests. The ErgoCut is just under 2.5m tall, which makes it ideal for confined spaces. The components are positioned on the product intake of the lower table, which swings up when the cycle starts. Once locked in place, the punching units located in the fixed upper component begin trimming.

Request for a quote

FRIMO GROUP GMBH

Germany

Economic and high performance punching machine for high volume production FRIMO's EcoCut punching machine is ideally suited for trimming very complex and large plastic components such as instrument panels, door panels and armrests. Its high capacity makes it the optimal choice for large-scale production. The EcoCut has been specifically developed for trimming towards the ram and in many additional punching directions. The product fixture is integrated directly into the lower table. The vertically driven upper tool replaces the press ram.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins FRIMO's scoring process technology was developed for producing hidden airbags in instrument panels. In contrast to composite component weakening in which the substrate, foam and skin are all weakened in one step, FRIMO prefers material specific single steps. The foil or skin is weakened by blade before foaming. The substrate and foam are separately weakened at the end, which can easily be integrated into the necessary component cutting process. Depending on the customer-specific requirements, this is where FRIMO punching machines or milling machines come into play. Compared to weakening entire composite components (for example, with a laser), a lower investment is required. For the weakening of leather parts for hidden airbags, FRIMO offers a patented process in which the skin is weakened by a rotating circular knife. This process guarantees high precision and odorless results with the shortest possible cycle times.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METALOCK INTERNATIONAL ASSOCIATION LTD

United Kingdom

For the repair of cracked or fractured castings in all types of press equipment. The repair is carried out in-situ, with little or no dismantling. The repair is completed in hours, eliminating the need for an expensive replacement. Repairing presses since 1949

Request for a quoteResults for

Punching machines - Import exportNumber of results

7 ProductsCountries

Company type