- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum pumps

Results for

Vacuum pumps - Import export

ZEPTER INTERNATIONAL

Switzerland

The Vacuum Pump forms the heart of Zepter’s VacSy® System that draws out air and contaminants from the food containers. A user-friendly and versatile vacuum system, it can be combined with VacSy® containers, products from the Zepter Masterpiece Cookware line, as well as many commercial containers. Using smart wireless technology, the VacSy® pump brings you the advantages of mobile and easy handling – anytime, anywhere. 5x Longer Food Freshness: Like its predecessor, the Vacsy Pump Deluxe removes air from containers to preserve food’s flavour, freshness, and shelf life. Keep your raw goodies and ready meals at their best for up to 5 times longer than in traditional refrigerator conditions. Unmatched Versatility: Vacuum-pack fresh or prepared foods and drinks directly into VacSy® Containers, Bottles, Bag Rolls or Zepter Cookware. Experience the convenience of preserving your culinary creations in organized, mess-free and diverse way.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Pump Services Our services range from standard inspections and repairs to complete overhauls. A repair or overhaul of a pump generally consists of an Inspection, Repair/Modification and a final Report. Inspection The first step when repairing any pump is the inspection. Pump inspections include: Visual inspection Measuring axial positions and clearances Disassembly + visual inspection of parts Dimensional measurements Check of probes and sensors (if present) Oil sampling & check When the inspection is finished, an inspection report is drawn up with recommendations for repair. Execution of works After approval of the recommendations for repair, the execution of the repair / overhaul works begins. The scope of work may vary, but can include: Cleaning & steaming Sandblasting Preparation of technical drawings for machining by in-house engineering team Machining of parts (bearing housings, rotors, …) Balancing of rotating parts Coating of rotating parts

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Pump VP-TS Design Cap. (m³/h) Vacuum (mbar) Power (kW) oilless, silenced 16 ... 50 -850 ... -850 0,55 ... 1,25

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Safety Tank VFS Capacity (l) 15 ... 200

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Energy Unit VEE-T Contents (l) Cap. (m³/h) Vacuum (mbar) with oilless pump 15 ... 200 4 ... 40 -850 ... -900

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Energy Unit VEE-0 Design Contents (l) Cap. (m³/h) Vacuum (mbar) with oil-lubricated pump 15 ... 200 10 ... 160 -980

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Silencer Box SDB Reduction of noise level (dB(A) -5 ... -10

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum-controlled Motor Switch VMS Saving energy on vacuum pumps

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Motor Protection Switch MSS Overload protection of vacuum generators

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Blower SKE Design Cap. (m³/h) Vacuum (mbar) Power (kW) belt-driven 160 ... 290 -500 2,2 ... 4,0

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Blower SD Design Cap. (m³/h) Vacuum (mbar) Power (kW) w/ fly-wheel 170 ... 280 -180 ... -250 1,1 ... 2,3

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Blower SKV Design Cap. (m³/h) Vacuum (mbar) Power (kW) directly driven 40 ... 720 -150 ... -400 0,37 ... 9,0

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Pump VP-0 Design Cap. (m³/h) Vacuum (mbar) Power (kW) oil-lubricated 10 ... 250 -980 0,37 ... 7,5

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Pump VP-TF Design Cap. (m³/h) Vacuum (mbar) oilless, 24V 0,65 ... 8 -800 ... -850

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Pump VP-T Design Cap. (m³/h) Vacuum (mbar) Power (kW) oilless 4 ... 140 -850 ... -900 0,18 ... 5,5

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter VF Connect. G3/8 ... G21/2 Vacuum filter with sheet metal housing for vacuum pumps and smaller blowers

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Vacuum Filter VFT Connect. G1/8 ... G1/2 Vacuum filter made of plastic with clear glass lid for ejctors and small vacuum pumps

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

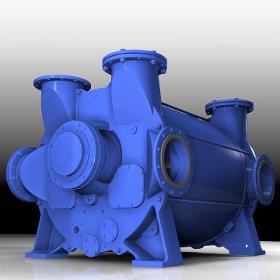

100 - 3600 CFM / 170 to 6,100 m³/h The NASH SC vacuum pump and compressor, which replaced the popular NASH CL pump in the 1980's, is still being manufactured at Gardner Denver Nash. The SC pump, more flexible and simpler to install and easy to maintain, made it a very reliable pump to be used in many applications. SC pumps are found in applications including: autoclaves, chucking, container filling, labeling and forming, cooking, deaerating, deodorizing food and fats, drying, evaporating, eviscerating, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, laboratory central vacuum systems, medical and dental vacuum draining, molding, pickup and conveying, priming, slot extraction, and solvent recovery. All SC models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing SC pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate SC pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 904 , which replaced the popular NASH CL pump in the 1980's, can still be found at Gardner Denver Nash. Capacities of the 904 pumps range upward from about 3,000 CFM at vacuum. These durable pumps can handle excess liquid carryover without any difficulty, even if it arrives as massive slugs. 904 pumps are found in many industries including Paper, Chemical, and Mining. All 904 models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing 904 pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate 904/905 pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

14000 - 22000 CFM / 24,000 to 38,000 m³/h Designed to operate in demanding environments such as paper, power, mining and chemical process industries, this pump combines durability and reliability with low operating costs. The P2620 has a polyisoprene-lined body for corrosion and erosion resistance. This is a standard feature. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. Bottom and side discharge connections offer flexibilty to address installation space constraints. The P2620 pump allows efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 10 in. Hg (340 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. Performance ranges from 14,000 to 22,000 CFM (24,000 to 38,000 m³/hr). For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

3000 - 16000 CFM / 5,100 to 27,200 m³/h The NASH 905 series has been designed to provide superior reliability and performance in harsh applications such as chemical processing or geothermal power generation. Constructed of 316L stainless steel, the 905 series offers excellent corrosion resistance and can be outfitted with a variety of mechanical seals. It also includes a patented gas scavenging feature. All 904 models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing 904 pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate 904/905 pump, Gardner Denver Nash is there for all of the above.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 pumps, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

170 - 14000 CFM / 240 to 23,700 m³/h The NASH CL Vacuum Pump and Compressor product line is perhaps the most popular ever built. There are 12 different models, from the CL-200 through the CL-14000, with capacities ranging from 150 CFM to over 14,000 CFM. They can be found in many applications including: autoclaves, carburetor testing, chucking, condenser exhausting, container filling, cooking, deaerating, drying, eviscerating, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, molding, pickup and conveying, priming, slot extraction, and solvent recovery. All CL models are still available from Gardner Denver Nash, the original designer and manufacturer. Whether you have an existing CL pump running in your plant that is in need of service, repair, or replacement with a new or remanufactured duplicate CL pump, Gardner Denver NASH is there for all of the above. Gardner Denver Nash continues to manufacture and offer the CL to our customers.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

1500 - 19000 CFM / 2,500 to 33,000 m³/hr Nash's 2BE3 & 2BE4 vacuum pump series offers capacities ranging from 1,500 to 19,000 CFM (2,500 to 33,000 m³/hr). Designed to operate in demanding environments like the paper, power, mining and chemical process industries, these pumps offer durability and reliability at a low cost of operation. Each model is equipped with an application-proven polyisoprene-lined body for added corrosion & erosion resistance. The unique inlet configuration allows for both top and side inlet arrangements to accommodate low headroom installations. In installations where space is limited, the top discharge capability of the 2BE4 allows the use of a top mounted discharge separator that saves floor space and eliminates the need for a trench. The pumps allow efficient operation over the entire vacuum range without the need to change the pump's internals. When equipped with a center shroud, split vacuum operation up to 12 in. Hg (400 millibar) differential can be achieved. Large inspection ports allow easy access to pump internals for inspection and maintenance. For more aggressive applications, stainless steel, stainless steel clad and epoxy coated components are available.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

15 - 140 CFM / 35 to 210 m³/h Designed from the ground up to meet the widespread needs of the process industry, the Vectra SX adds five models to Nash’s Vectra series in the 1 ½ to 10 HP range at 60 Hz (0.75 to 5.5 kW at 50 Hz), providing the right solution for small capacity vacuum pump requirements. Designed to use less energy and consume less operating liquid than competitive models, it is possible to save the user as much as 40% on power consumption and 50% on water usage.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

15 - 5300 CFM / 195 to 9,100 m³/h The NASH Vectra was designed around a modular platform using the most advanced computer aided design techniques, such as 3D solid modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions with numerous common parts. The Vectra GL model, available from 120 to 830 CFM (200 to 1,500 m³/hr), is ideal for general industrial applications. It comes standard with internal mechanical seals and many Nash patented innovations including gas scavenging. The Vectra XL model was designed to meet the stringent requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it features a 30 PSI (2 bar) differential capability. It is available in ductile iron or 316L stainless steel with a variety of shaft sealing options. Sizes range from 120 to 5,300 CFM (200 to 9,000 m³/hr). The NASH Vectra can be operated within a wide range of operating speeds, with numerous 50 and 60 HZ direct drive speeds. This increased turndown capability makes them ideal for varying load applications when driven by VFD's.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

125-2100 CFM / 210 to 3,560 m³/h The NASH TC/TCM liquid ring vacuum pumps are highly reliable and efficient. These pumps, with their integral two stage impeller, are able to condense process vapors and to recover or dispose of the vapors. Another benefit of these pumps is that they can attain vacuum levels down to 0.8" HgA (20mmHgA). This is approximately 40 percent lower absolute pressure than a single stage pump. The NASH TC and TCM models are designed to handle large amounts of liquid carryover without difficulty. This ensures reliability under the most demanding applications.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

Priming Valves for Liquid Ring Vacuum Pumps Gardner Denver Nash priming valves were designed specifically to be used in Nash vacuum pump priming systems. They are extremely simple, dependable and durable. It has been proven in successful service for nearly fifty years. A Nash vacuum system is often used to prime one or more centrifugal pumps located above the free liquid levels of their suction sources. Vacuum draws liquid up until it fills each pump's suction line and floods its volute. This condition can be established before the pump is started up, so that it is always primed and ready to begin pumping. A Nash vacuum system is often used to prime one or more centrifugal pumps located above the free liquid levels of their suction sources. Vacuum draws liquid up until it fills each pump's suction line and floods its volute. This condition can be established before the pump is started up, so that it is always primed and ready to begin pumping

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

10 - 75 CFM / 17 to 127 m³/h NASH has been providing vacuum pumps and packages in shipboard priming applications for over 50 years and continues to offer a wide range of classic products for this service. The single stage MD570, MD670, MHC, and MHF series are available in a variety of materials including bronze, copper nickel, and stainless steel. These pumps are provided close coupled to a marine duty motor have capacties ranging from 10 to 75 CFM. If deeper vacuum is required, the two stage AT34 & AT64 pumps are available with capacties ranging from 30 to 75 CFM.

Request for a quoteResults for

Vacuum pumps - Import exportNumber of results

46 ProductsCountries

Company type