- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet shearing

Results for

Sheet shearing - Import export

GSW SCHWABE AG

Germany

Cut-To-Length Lines are core competence at GSW. They belong to the family of Cutting Lines and are designed to process diverse materials out of steel, non-ferrous metals or aluminum and precisely cut a coil into sections of equal length (which is where the name comes from). Starting with narrow slit strip and finishing somewhere beyond 2000mm width – our Cut-To-Length Lines always know how to shine in this process.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

This how each cut is made Sheet metal is available in a very wide range of materials and alloys. The criterion for machining is a given toughness and strength to make the metal sheets deformable. A part of sheet metal machining is separation by shearing, in which the sheets are divided by two shearing knives. For over 40 years, we have supplied shearing knives in lengths up to 4,190 mm in qualities and hardnesses specially matched to the purpose for the corresponding machines. By using peripheral grinding machines, we can comply with the tightest form and position tolerances, which is why so many machine manufacturers rely on the quality of our shearing knives.

Request for a quote

ROCHOLL GMBH

Germany

We produce blanks from plastic in line with your specifications. Upon your request, we also process pellets specified and also provided by you in our injection molding department. We keep a wide range of common plastic grades in stock, which we process into test specimens of various sizes according to your specifications. On request we also procure special materials and process these in line with your specific requirements. We process every available type of pellets to form DIN A5 format sheets or smaller sheets lap shear test specimens 100 x 25 x 3 mm dumbbell test specimens We deliver various surface finishes structured high-gloss automotive graining used by a wide range of car manufacturers We deliver every SMC quality depending on the availability of prepregs with class-A finish also in automotive quality Types of plastics ABS, PC, PE, PMMA, POM, PP, PS, PVC, PET, PTFE, PA6, PA6.6, PU, Polymer-based glass fiber-reinforced plastics

Request for a quote

ALUMERO SYSTEMATIC SOLUTIONS GMBH

Austria

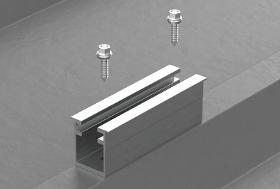

Simple mounting on aluminium and steel trapezoidal sheet roofing Non-shearing attachment via special drilling screws Pre-installed EPDM rubber provides additional sealing between roofing and trapezoidal bridge Module can be mounted vertically or horizontally Designed for roof gradients of 5° to 35°

Request for a quote

ALUMERO SYSTEMATIC SOLUTIONS GMBH

Austria

Simple mounting on aluminium and steel trapezoidal sheet roofing Non-shearing attachment via special drilling screws Pre-installed EPDM rubber provides additional sealing between roofing and short rail Module mounted horizontally Clamping on the long side of the module Designed for roof gradients of 5° to 25°

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

COSTRUZIONI METALMECCANICHE VALENTE

Italy

At our Nole plant we have an architectural and structural metalwork department where multiple operations are performed. Our ability to work different materials (common and alloy steel, stainless steel, aluminum etc) and the machinery we use combine to make our company a leader in the industry. In particular, we deal with: Sheet metal processing: shearing, press-bending, calandering, drilling and notching; Welding and joining of different materials in TIG, arc, and continuous wire modes; Construction and installation of several different types of metal structures, using tubular materials, profiles, beams and semi-finished parts;

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The CIDAN RAPIDO is a heavy duty built mechanical sheet metal guillotine shear. It will cut material with thicknesses from minimum to maximum without any settings at all. This shear again proves our philosophy regarding the environment as it uses very little energy and has a very low noise level. The shear is well equipped as standard and also has a wide range of options such as different back gauges systems including sheet handling systems.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The CIDAN EVO is the strongest mechanical sheet metal guillotine shear in the Cidan program. The EVO is supplied with blade gap adjustment as a standard feature. The blade gap adjustment makes it possible to achieve the best cutting result in all kinds of sheet thicknesses. The blade gap is set quickly and correctly via handles and scales.

Request for a quote

SELMACH MACHINERY LTD

United Kingdom

The RVD LFTS Sheet Metal Treadle Guillotine is manufactured with a strong cast iron frame and equipped with front and rear gauges and rear guard. Ideal for fast shearing of thin sheets. The treadle design allows for hands free operation for accurate positioning of material. An ideal machine for general use with thin sheets, we also have a range of more heavy-duty guillotines too.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

ECKOLD servo motor-driven shear clinching system for automated production. Shear clinching allows for the joining of sheet metal of high strength and soft materials (e.g. aluminium and steel). The rivet-free joining technique is a cost-effective alternative to self-piercing riveting systems. • No prehole necessary • No thermal stress at joining point • No poisonous gases or vapours • Suitable for joining metal sheets of equal and different materials and sheet thickness • Joining of sheet metal elements of varying thickness This offer includes: Servo motor-driven shear clinching system • Clinching frame incl. scrap extractor, horiz. throat of approx. 300 mm • Control cabinet incl. software ECKOLD VISU Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

The MCSB/2B-900 is a 900mm wide belt and brush/roll dry working Grindingmaster that is equipped with powerful motors allowing it to process the toughest and heaviest jobs around. R.P.M.1500 Hp/Kw15 + 7.5 kW Typical process applications covered by this machine: Stock removal of multiple individual parts and sheet materials Grain and scratch brush finishing of any material. Sizing and finishing of parts and sheet materials Deburring punched, nibbled, sheared or laser-cut sheet metal parts. Calibrating or keying carbon, rubber, wood or other soft materials.

Request for a quoteResults for

Sheet shearing - Import exportNumber of results

12 ProductsCompany type

Category

- Shearing - steels and metals (3)

- Roofing, solar protection (2)

- Blades and knives, industrial (1)

- Industrial sheet metal work (1)

- Metal straightening machines (1)

- Planing lathes, automatic (1)

- Plastic material processing (1)

- Rolling mills - machinery and installations (1)

- Steels and metals - forming and cutting (1)