- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- static mixers

Results for

Static mixers - Import export

FLOWLINK BV

Netherlands

Equipment for accurate additive injection and dosing

Request for a quote

FLOWLINK BV

Netherlands

Static Mixers for low viscosity / high Reynolds number flows

Request for a quote

FLOWLINK BV

Netherlands

Static Mixers for high viscosity / low Reynolds number flows

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Insufficient surface quality, long cooling times, uneven thickness tolerances or other quality problems often limit maximum production output. Promix melt blenders eliminate these limitations sustainably and lead to significant cost savings. Would you like to optimize your extrusion process? Improved melt homogeneity and a more uniform melt temperature create tighter thickness tolerances and better surface quality. And quite often, it can also increase production throughput. Promix offers you highly effective static mixers and melt blenders at low investment costs. They are supplied ready for installation, including heater bands and holes for pressure and temperature sensors. The melt blenders are usually installed downstream of the screen changer & gear pump, and upstream of the die. The very short installation length allows easy retrofitting in existing extrusion lines.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Mixing nozzles and static mixers from Promix ensure excellent melt homogeneity and efficiently prevent color streaks or flow lines. Quality problems in injection molding are often solved by modifying the process parameters. Masterbatch concentration and back pressure must be increased, which makes production costs more expensive. This does not have to be the case! Mixing Nozzles from Promix ensure excellent melt homogeneity. Color streaks or irregularly distributed additives in the component are a thing of the past. The ready-to-connect mixing nozzle is installed on the injection molding machine replacing the standard nozzle. Contact us for a mixing nozzle to test.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS SCR catalytic converters: - SCR housing with insulation - Optimised design of the catalytic converter honeycombs - Injection section with static mixers - Daily service tank - Dosing station for exact dosing of the reducing agent - Continuous measurement of nitrogen oxides (NOx) - Controlled urea injection at measured NOx values - High conversion rate and long service life

Request for a quote

KASAG SWISS AG

Switzerland

Heating system for jams and marmalade The KASAG heating system for jams is used at industrial baking lines for preparing jams and marmalade. Jams or marmalade are conveyed with a pump via heated pipes. Static mixers ensure excellent heat transmission and very short process times. Tempering unit for chocolate for chocolate The KASAG tempering unit is used for heating, cooling, maintaining the consistency of the chocolate and for optimising production processes with chocolate.

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • A single solution for everything: Building authority approval for cracked & uncracked concrete, perforated and solid masonry and additional reinforcement connections • LEED and emission tested: for ecological and healthy living • Usual threaded rods* can be used • Earthquake tested C1 • Processing even possible at extremely low temperatures (down to -10° C) • Can be used in wet and water-filled drill holes • Small axis and edge distances for anchoring without spreading pressure • Fixing of high loads weighing up to 13.3 tonnes • Can also be processed overhead • Reuse of the broken cartridge by changing the static mixer • Variable anchoring depth – saves time and material *according to Approval Description & Area of Application • Liquix Pro 1 is a styrene-free, vinylester injection mortar available in various cartridge types and cartridge sizes with static mixer Liquix Mix • For approval-relevant fixings in cracked and uncracked concrete and masonry

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Aluminum cartridges protect the sealing compound with a diaphragm and seamed lid to prevent leakage, ensuring a long shelf life and preventing the contents from drying out. The two-component integrated system is suitable for fast-curing fillings and easily used with existing guns on the market while offering a variety of static mixer nozzles. Cartridges can be printed with customized art in up to six colors and have lacquer applied to the inside surfaces. Products include cartridges and a two-component integrated system.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix specializes in demanding cooling and heat exchanger tasks such as cooling and heating of viscous or decomposition-sensitive media / plastic melts. The Promix P1 heat exchanger is the unique combination of a very efficient static mixer and a powerful cooler. The novel patented technology opens up completely new process engineering possibilities in the cooling and heating of plastic melts and other viscous fluids. The simultaneous mixing and cooling processes in the P1 allow for very efficient cooling and heating without the formation of deposits or the risk of product decomposition. Advantages Promix P1 heat exchanger Very efficient cooling of polymer melts close to the solidification point Precise temperature control and uniform temperature distribution at the outlet Very robust construction Extremely gentle cooling and heating of residence time critical fluids Unique self-cleaning behavior Reliably scalable from laboratory test to production scale Test options

Request for a quote

ROCHOLL GMBH

Germany

As a full-service provider of test specimens made of a wide range of materials, we are expanding our processing expertise in cooperation with our customers. We would like to use this expertise for your benefit. As we have grown our product range to include cartridges, you will benefit from our contacts to all leading suppliers and will be able to choose from a huge variety of cartridge guns and accessories to find the right products that meet your needs. Our competent partner service will be happy to assist you in case of problems: We maintain and repair your cartridge guns properly, provide spare parts, conversion kits and accessories from all well-known brands. State-of-the-art cartridge guns and an incredible variety of accessories enable you to work professionally. Cartridge guns for 1-and 2-component cartridges Manual guns Pneumatic guns Battery guns Accessories Nozzles Static mixer Dynamic mixer Empty cartridges Service New equipment

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Heavy-duty spacer installation for ETICS, clinker or on flat roofs • Aqua-Stop effectively protects against rotting of the facade due to moisture • Stainless steel prevents unsightly rust stains • Approved by the building authorities • Practically no energy loss • Simple and rapid installation • Smoothly adjustable insulating sleeve Iso Spacer • Suitable for insulation thicknesses and spacer installations up to 200/300 mm Description & Area of Application Thermo Proof is a heavy-duty spaced mounting system for thermally-insulated facades (ETICS) consisting of: • Iso Spacer with large contact surface and SW24 driver for better force transmission • Aqua-Stop special sealant for exterior use; incl. dosing tip; content 80ml; transparent colour • Steel parts made of stainless steel in A4 quality; M12 thread; length 300/400 mm • Static mixer extension for deep drill holes

Request for a quote

INOEX GMBH

Germany

SAVEOMAT Liquid is the multi-component dosing station for the recipe-precise dosing of solid and liquid components. The use of silane and peroxide is especially applied in PEXa and PEXb pipe extrusion and cable production. Precise mixing of the raw material is achieved by combining a static and a dynamic mixer. An injection tube is integrated in the dynamic mixer, whereby the peroxide or silane is introduced and ensures uniform wetting. Thanks to its safety features, SAVEOMAT Liquid meets the highest safety requirements while allowing a wide range of recipes. Other advantages/features: — Recipe-accurate dosing and conveying —Constant wetting of the raw material — Meets the highest safety standards — Dosing and mixing of materials under inert gas atmosphere — Reduction of the peroxide percentage by approx. 10 % through uniform and continuous metering

Request for a quote

MPT DOSING GMBH

Germany

/ Static Inline Mixers Dynamic Inline Mixers Dynamic inline mixers have, contrary to static mixers, a driving motor with variable agitator speed, providing for the required mixing energy. The main field of application for dynamic inline mixers is the intensive and adjustable mixture of polymer flocculation agents with the sludge to be dewatered on dewatering machines like (belt) filter presses. Using dynamic inline mixers the active ingredient contained in the polymer is dispersed evenly in the sludge to be dewatered, resulting in a noticeable improvement of the dewatering characteristics and a considerable reduction of the required flocculation agent. A suboptimal mixture of the flocculation agents is often compensated by a considerable increase of the dosed quantity. In many applications the flocculation agent is dosed in a stronger dilution to improve the miscibility. However, this means that water which actually should be detracted from the system is now added to the system. I

Request for a quote

SAMES KREMLIN

France

The Cyclomix™ Expert is an innovative, industrial solution that is configured to meet the needs of the customer. Description Capable of metering 1 component as well as mixing 2 and 3 component materials Flexible modular design - up to 24 programmable components PH version available for acid-catalyzed coatings Handles up to 50 receipes Constant flow technology Performance Production flush 5-step programmable sequence Weekend flush 6-step p rogrammable sequence Continuous ratio and pot life monitoring Multiple flowmeter options availbable to meet your requirements Productivity Consistent finish quality Reduce labor - on demand mixing In-line static mixer reduces flushing solvent and faster color changes Reduced fluid waste Less rework Reduced hazardous waste Sustainability All stainless-steel construction compatible with most materials PH (acid catalyst) version available Filter/regulators assemblies are standard equipment, constructed of stainless steel compatible with most material

Request for a quote

SAMES KREMLIN

France

The Cyclomix™ Expert is an innovative, industrial solution that is configured to meet the needs of the customer. Description Capable of metering 1 component as well as mixing 2 and 3 component materials Flexible modular design - up to 24 programmable components PH version available for acid-catalyzed coatings Handles up to 50 recipes Constant flow technology Performance Production flush 5-step programmable sequence Weekend flush 6-step p rogrammable sequence Continuous ratio and pot life monitoring Multiple flow meter options available to meet your requirements Productivity Consistent finish quality Reduced labor - on demand mixing In-line static mixer reduces flushing solvent and faster color changes Reduced fluid waste Less rework Reduced hazardous waste Sustainability All stainless-steel construction compatible with most materials PH (acid catalyst) version available Filter/regulators assemblies are standard equipment, constructed of stainless steel compatible with most...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STAMIXCO AG

Switzerland

DN 35mm O.D. = 34,7mm x 110mm long, made of PP.

Request for a quote

STAMIXCO AG

Switzerland

Installation of static IMV mixing elements in a pipe DN 1400 mm for dispersing of a 10% w/w ozone/oxygen-gas stream into fine bubbles. This results in a large interfacial gas/liquid contact area and thus a high ozone absorption rate of the ozone in the water stream to be treated is achieved. The ozone/oxygen-gas stream is added through the side-nozzle DN 200 mm. Mixer is made of stainless steel AISI 316L (= 1.4404), pickled and passivated. This static mixer IMV DN 1400 mm is installed in a water treatment plant in France, for pre-ozonation of 1500-8000 m3/h water with 1g/m3 ozone. Pre-ozonation Static Mixer D1400mm forTreatment of 1500-8000 m3/h Water.Outlet-side of the Ozonation Mixer IMV DN.

Request for a quote

STAMIXCO AG

Switzerland

Static mixer GXM für admixing of a low viscous additive to a viscous liquid/melt.

Request for a quote

STAMIXCO AG

Switzerland

Mixer Pipe (O.D. = 30mm, Wall = 3mm, Lenght = 450mm) Mixer and Pipe made of PP.

Request for a quote

STAMIXCO AG

Switzerland

dia. and length 7.9 mm each, made of stainless steel 1.4542 (= 17-4 PH or A630) are now available from Stamixco’s stock. These static mixing elements are often installed into spinning plates of man-made fibre plants. Also a frequent application is in paint finishing systems for in-line mixing reactive paint components in the paint feed-hose just upstream the spray nozzle.

Request for a quote

STAMIXCO AG

Switzerland

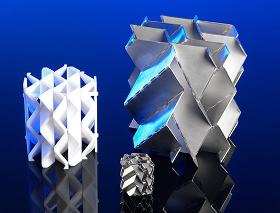

StaMixCo manufactures a wide variety of plastic disposable static mixers for 2-component (2K) meter-mix-dispense applications. The available product range is under constant development. So please do not hesitate to contact us directly for specific requests. X-Grid Plastic Disposable Static Mixers (High Performance) For difficult mixing applications where materials to be mixed have large differences in viscosity and volumetric ratio or when a very high degree of mixing is required, the X-Grid static mixer designs are best. The X-Grid family of static mixers has the characteristic feature of an X-Grid crossing bar structure. They are best suited for difficult mixing applications where the components to be mixed have large differences in viscosity or volumetric ratio and where a very high degree of mixing is required. These demanding applications are often found in the processing of adhesives, varnishes, urethanes, sealants, liquid silicone rubber (LSR), polyols, etc. The GXF plastic disposable static mixer is available in a 10 mm diameter size with 6, 9 and 12 mixing elements. It is used for processing small flow rates in difficult meter-mix-dispense applications such as adhesives, varnishes, urethanes, sealants, liquid silicone rubber (LSR), etc. The GXP plastic disposable static mixer is available in a 9.4 mm diameter in 50% glass filled Nylon and polypropylene construction. It is used for processing small flow rates in difficult meter-mix-dispense applications such as adhesives, varnishes, urethanes, sealants, liquid silicone rubber (LSR), etc. The GXR-P plastic static mixer is available in a 30.1 mm size in 50% glass filled Nylon and polypropylene construction. It is used for processing large flow rates in difficult meter-mix-dispense applications such as adhesives, varnishes, urethanes, sealants, liquid silicone rubber (LSR), etc. The industry standard helical plastic disposable 2K static mixer is available in a very wide range of diameters, number of mixing elements, configurations and materials. It is most suitable for easy to moderate difficulty meter-mix-dispense applications. Static Helical MixerDN 35mm O.D. = 34,7mm x 110mm long, made of PP Static Helical Mixer with 4 helical elements and a total length of 110 mm for bores/pipes with I.D. of 18 to 34.7 mm, made of PP. Available in standard diameters of 18, 20, 25, 30, 34.7 mm or on request in special diameter in the range of 18–34.7 mm. Applications: Disposable static mixer for 2-components (2K) metermix-dispense, for pH-adjustment with acid or caustic (neutralisation) in watertreatment or for general mixing duties with fluids not corroding PP. Helical static mixer with fins O.D. = 24mm Mixer Pipe (O.D. = 30mm, Wall = 3mm, Lenght = 450mm) Mixer and Pipe made of PP.

Request for a quote

STAMIXCO AG

Switzerland

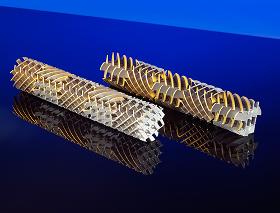

StaMixCo manufacturers all three commercially proven static mixer designs used for high viscous melt flow mixing of polymers in extrusion service. As with most process equipment, each static mixer design has specific advantages and disadvantages that make it more or less suitable for a specific application and installation. Each type of motionless mixer is discussed below: Process Improvements: Temperature gradients are virtually eliminated. Viscosity gradients are virtually eliminated. Composition gradients of colorant, chemical additives, fillers and regrind are virtually eliminated. Stagnant polymer wall-creep material is incorporated into the bulk polymer stream. Extrusion Applications Static Mixers are used in most extrusion applications including the following: Sheet Blown Film Foam sheet Profile extrusion Co-extrusion Pipe Extrusion Blow Molding Rod & Tubing Wire & Cable Coatings Fiber extrusion & monofilaments Benefits Reduction of color additives with comparable extrudate color density. Even thickness across the entire extrudate width. Streak-free product. Improved quality when using regrind material. Foam cell size and cell distribution uniformity. Improved surface quality Improved mechanical characteristics. Rapid color change-over SMB-R Static Mixer SMB-GXS Static Mixer Mixing of blue and white epoxy resin with the SMB-GXS Static Melt Blender. It improves the melt homogeneity by factor 5-6. SMB-R Static Mixer The SMB-R static mixer for extrusion service (licensee of Bayer AG, Leverkusen, Germany) contains eight (8) very efficient motionless mixing elements that homogenize the polymer melt as it enters the extruder die. The SMB-R mixing elements are considered as high performance design where they create a very high degree of mixing in a short length. The SMB-R mixing elements are virtually indestructible due to their monolithic cast construction where the mixing bars are jointed to each other and to the ring wall via a single molten metal pour. Mixing of blue and white epoxy resins. Empty tube (top)provides no mixing. Eight (8) mixing elements (bottom) provide an excellent mix quality in a short length. SMB-GX Static Mixer Melt Blender The SMB-GX motionless mixer is a design that has been used in melt flow mixing extrusion service for over 25 years. The SMB-GX mixing elements are considered as high performance design where they create homogeneous mix in a short length. It has the same fundamental X-Grid crossing-bar structure as the StaMixCo SMB-R static mixer (Figure #8), but without the support ring around the mixing blade structure which gives the SMB-R its remarkable strength. Since the SMB-GX is manufactured from metal plates that are welded together, virtually any custom static mixer plate thickness, material and diameter can be fabricated to meet process and installation requirements. SMB-H Static Mixer Melt Blender The SMB-H Helical static mixer design pioneered the static mixing industry and has been used as a viscous static mixer on extruders for over 37 years. The Helical design is considered a low mixing performance-long length-low pressure drop motionless mixer as compared to the later developments of high performance static mixers such as the SMB-R and SMB-GX which have become the technology standards in the industry. StaMixCo manufactures SMB-H static mixers by advanced proprietary manufacturing technique where the entire unit is machined from a solid rod of bar stock material without welding. This machining process allows for custom static mixer fabrication in virtually any L/D twist, in very small sizes, with very high strength, straight and true dimensioning and with a RMS 12 mirror polish surface finish which is a much improved surface finish as compared to the traditional 32 RMS finish for the twisted and welded design.

Request for a quote

STAMIXCO AG

Switzerland

The GX static mixer has been used successfully for the laminar flow mixing and/or dispersion of viscous fluids for over 35 years. It is a high performance static mixer capable of mixing materials with equal or very large differences in viscosity and volumetric ratio. Mixing is accomplished in a short length with a very high degree of mixing. Mixing Capabilities Mix fluids with similar viscosity Mix fluids with high and low viscosity (1 million : 1) Mix fluids with large differences in volumetric ratio (1,000 : 1) Disperse and mix polymers with blowing agents Thermal homogenization Viscosity homogenization Applications Polymer manufacture and processing. Two (2) component viscous materials such as Liquid Silicone Rubber (LSR), adhesives, polysulfide, sealants, epoxy resins, polyurethanes, etc. Plastics Extrusion Materials of Construction, Housings and End-Connections The GX static mixer can be supplied in most materials of construction, pipe/tube housings with virtually any end connection (Figure #13). GX-P mixing elements in 9.3 - 9.4mm outside diameter size are also available in plastic construction. History of GX Static Mixing Structure The GX static mixer was invented by Bayer AG of Leverkusen, Germany in the mid 1970’s. Bayer used the GX static mixer extensively in their polymer plants and subsequently licensed the design to Sulzer Chemtech of Winterthur, Switzerland who trademarked the design as the SMX* static mixer. Sulzer did a tremendous amount of fundamental high quality R&D work on the SMX structure and commercialized the SMX static mixer in tens-of-thousands of successful installations. The founders of StaMixCo held key technical and management positions in the Koch Engineering (the later Koch-Glitsch)-Sulzer Chemtech team that commercialized the SMX static mixer. Bayer licensed their 2nd generation of the SMX static mixer to StaMixCo which is branded as the GXR structure with integral support ring around the X-Grid mixing bars as described in a previous section of this web site. * StaMixCo is not a distributor of or affiliated with Sulzer Chemtech. SMX is a brand and trademark of Sulzer Chemtech.

Request for a quote

STAMIXCO AG

Switzerland

The GXR Static Mixer (Licensee of Bayer, AG) is used for mixing, dispersing and homogenization of viscous materials. It is a high performance motionless mixer design that creates a very high degree of mixing in a short length. It is capable of mixing materials with very large differences in viscosity and volumetric ratios. Mixing Capabilities Mix fluids with similar viscosity Mix high and low viscosity fluids (1 million : 1) Mix fluids with large differences in volumetric ratio (1,000 : 1) Disperse and mix polymers with blowing agents Thermal homogenization Viscosity homogenization Applications Two (2) component viscous materials such as Liquid Silicone Rubber (LSR), adhesives, polysulfide, sealants, epoxy resins, polyurethanes, etc. Plastics Injection Molding Plastics Extrusion Polymer manufacture and processing The mixing elements may be safely pressed out of the housing by pushing on the support ring which avoids any damage to the mixing grid The GXR mixing elements are presently also available in inexpensive plastic construction (50% glass-filled Nylon and polypropylene) Helical Static Mixer The HT helical static mixer pioneered the inline motionless mixing industry over 40 years. It is a cost effective static mixer design with moderate mixing performance capabilities. It is most suitable for use in small diameter turbulent flow and laminar flow applications where the mixing task is simple and where it’s characteristic features of low pressure drop and open geometric structure are best for the specific application. For difficult applications, the high performance GX static mixer is recommended for laminar flow applications. The Helical static mixer is available in metal and plastic construction in a wide variety of configurations and sizes.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

We will develop the mixing process that is best for the mix of glue that the customer is working with and deploy static mixers, dynamic mixers or tank-mixer systems.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The APG-process by HÜBERS permits short cycle times thanks to rapid gelation and demoulding with automatic opening and closing of the mould. During the gelling process, fresh material is supplied continuously to the mould under pressure in order to prevent cracks and voids and to compensate for the shrinkage of the material. The mould is held together by the clamping machine. The degassed material is injected into the APG mould directly from the static mixer. Shrinkage compensation is carried out by the HÜBERS metering pumps. One central mixing and metering system can serve several clamping machines. In this case each clamping machine has its own static mixer positioned directly in front of the mould and also has its own shrinkage compensation unit to maintain the pressure. The system is supplied via a ring line which requires no maintenance and is free of sedimentation. In principle the length of this line is insignificant.

Request for a quoteResults for

Static mixers - Import exportNumber of results

29 ProductsCategory

- Pneumatic system components (3)

- Fastening devices (2)

- Caps, metal (1)

- Diesel engines (1)

- Dosing - machines and equipment (1)

- Electric and electronic components - machines for manufacturing (1)

- Fruit preserves and jams (1)

- Gunpowder (1)

- Mechanical engineering - custom work (1)

- Weighing and dosing equipment (1)

- Wood veneer - machinery and equipment (1)