- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel shot

Results for

Steel shot - Import export

WIWOX GMBH SURFACE SYSTEMS

Germany

Due to the different thermal tempering, steel shot blasting abrasives type WIWOX® SK obtain different hardness classes from 40 – 43 HRC, 54 – 60 HRC up to greater than 61 HRC. Because of the different degrees of hardness, the steel shot in the operating mixture keeps its angular shape or becomes round during the application process.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Due to its extreme hardness, WIWOX® SG high-carbon cast steel abrasive reaches an extremely high blasting intensity right from the start. It is produced in a melting process and gets its round shape through the subsequent atomising process. The metallic structure of this low-carbon cast steel abrasive is decisive for its long service life.

Request for a quote

ROKVELAS, UAB

Lithuania

At given need our experts can invoke extensive subcontracting.

Request for a quote

FERPLAST SNC

Italy

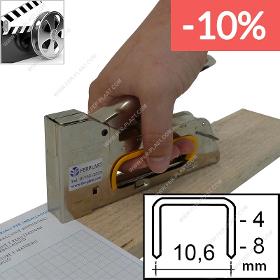

Stapler built entirely of chromed steel, shot without backlash, suitable for fixing of textiles, paper, plastic and other lightweight materials on the hardwood. Charging from below. This model is compatible with staples series 13 with lenght of 4-6-8 mm, total width of 10,65 mm, section 0,50x0,75 mm.

Request for a quote

MECASEM

France

Shot blasting is used for the production of metal parts subject to repetitive and cyclical stresses (landing gear, suspension parts, welding, engines, etc.). Faced with major safety constraints and problems of lightening the parts used, the interest of this technique is to be able to increase performance, slow down corrosion and increase the durability of the parts without increasing their weight. Our specialists can assist you in the development of your materials and products and in the control of industrial risks. At Mecasem, we have the latest shot blasting technologies at our disposal in order to best meet our customers' requirements. Our suspended load shot-blasting machine allows us to obtain a more varied range of impacts and opens up new perspectives for use.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MR CO. LTD.

Ukraine

The process is performed in closed chambers, where a jet of millions of glass microbeads, moving in a stream of compressed air, is directed on the product surface using a specialized gun. The abrasive removes all contaminants from the surface without changing the part geometry or damaging the product. It allows even fragile materials to be handled gently with this method. Controlled plastic deformation of the metal surface forms a light work-hardening that improves the service performance of the product. Due to the matting effect, this method is often used for finishing aluminum parts.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Continuous blasting – Excellent, highly automated processing The selected blasting medium is directed towards your workpieces at high speed using blast wheels. This ensures high blasting performance and optimum use of energy. Using this technology in a continuous process offers several advantages over batch processing: — Continuous workpiece feeding — Easy to integrate into production processes — Simplified parts flow That is why our continuous belt blasting units are frequently used to replace conventional batch systems. With their easy workpiece handling and excellent blasting results, they are even used as replacements for suspended-line systems.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Blasting is a structure-generating process for matt or satin-gloss surface structures. Small surface imperfections in the material can be concealed by the abrasive effect of stainless steel balls, which hit the material with the help of air pressure. Hand blast cabinet MHG Maximum measurements 2000 x 1000 x 1000 mm Blast cabinet Maximum measurements 400 x 400 x 200 mm

Request for a quote

SUBSIDIARY ENTERPRISE “DNIPRODZERZHYNSK STEEL WORKS"

Ukraine

Steel Shot S200 ISO 11124 Number of steel shot Sieve hole size for sieving, mm Sieve hole size for sieving, mm The permissible content of the residue on the screen, % < > S200 1,7-2,36 1,400 97 – 1,700 85 – 2,360 –

Request for a quote

SUBSIDIARY ENTERPRISE “DNIPRODZERZHYNSK STEEL WORKS"

Ukraine

This Steel Shot S660 is effectively used for blast cleaning shot peening, shot blasting and pre-treatment of the surface, steel board, steel structure and such other purposes.

Request for a quote

BV SRL SHOT BLASTING AND WASHING MACHINES

Italy

The main feature of the BV shot blasting equipment is the long resistance and duration in time of the machines that are constructed with special steel abrasive to the great thickness Manganese (fundamental characteristic for a shot blasting plant), equipped with single-disc turbines technologically advanced (built with materials wear-resistant cast iron Ni-Hard), and mechanical and electrical components Heads first level.

VITERI LIMITED

Cyprus

Abrasives: Shot(grit) blasting material(range of S-type, GH-types) according SAE&ISO Standards. Types: S230, S280, S780, S390, S550(Low-carbon), S780, S390, S550(Low carbon), S330 (Low carbon), S550, S170(Low carbon), S460 (Low carbon), GH25, GH40, GH50. High quality from Ukraine manufacturer

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

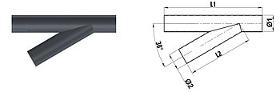

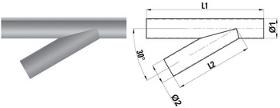

30° (stainless steel hardened) - stainless steel (hardened) - shot-blasted (steel balls) Ø1 (mm) Ø2 (mm) L1 (mm) L2 (mm) FS.30.040.15.040.15.CR.H 40 40 300 200 FS.30.050.15.050.15.CR.H 50 50 300 200 FS.30.060.15.060.15.CR.H 60.3 60.3 300 200 45° (stainless steel hardened) - stainless steel (hardened) - shot-blasted (steel balls) Ø1 (mm) Ø2 (mm) L1 (mm) L2 (mm) FS.45.040.15.040.15.CR.H 40 40 250 160 FS.45.050.15.050.15.CR.H 50 50 250 160 FS.45.060.15.060.15.CR.H 60.3 60.3 250 160

Request for a quote

ACHBERG SILOANLAGEN GMBH & CO. KG

Germany

30° - stainless steel - shot-blasted (steel balls) Ø1 (mm) Ø2 (mm) L1 (mm) L2 (mm) FS.30.038.15.038.15.CR 38 38 300 200 FS.30.040.15.040.15.CR 40 40 300 200 FS.30.045.15.045.15.CR 44.5 44.5 300 200 FS.30.050.15.050.15.CR 50 50 300 200 FS.30.060.15.045.15.CR 60.3 44.5 300 200 FS.30.060.15.050.15.CR 60.3 50 300 200 FS.30.060.15.060.15.CR 60.3 60.3 300 200 FS.30.065.15.065.15.CR 65 65 400 300 FS.30.070.20.050.20.CR 70 50 400 300 FS.30.070.20.070.20.CR 70 70 400 300 FS.30.076.20.076.20.CR 76.1 76.1 400 300 FS.30.080.20.080.20.CR 80 80 400 300 FS.30.084.20.084.20.CR 84 84 400 300 FS.30.089.20.089.20.CR 88.9 88.9 450 350 FS.30.100.15.100.15.CR 100 100 450 350 FS.30.102.20.102.20.CR 101.6 101.6 450 350 FS.30.104.20.104.20.CR 104 104 450 350 FS.30.108.20.108.20.CR 108 108 450 350 FS.30.114.20.114.20.CR 114.3 114.3 450 350 FS.30.129.20.129.20.CR 129 129 450 350 FS.30.154.20.154.20.CR 154 154 640 490 45° - stainless steel - shot-blasted (steel balls) Ø1 (mm) Ø2 (mm) L1 (mm) L2...

Request for a quoteResults for

Steel shot - Import exportNumber of results

15 ProductsCompany type