- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel wedges

Results for

Steel wedges - Import export

NORELEM FRANCE

France

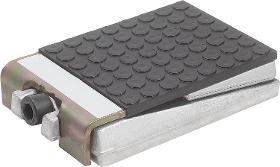

Steel, nitrile rubber. Note: The low non-slip levelling wedge is suitable for loads of up to 2 tonnes. The levelling wedge provides a large support surface with a nubbed structure made of nitrile with a hardness of Shore 80. Using the flat angle of the wedges, the height of the levelling wedge can be adjusted by 0.15 mm per turn of the screw. The vulcanized non-slip layer provides durable insulation from vibrations, noise, and corrosive media.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating Circular motion screens divide into several bulk grain size ranges, seven small amounts of over-or undersize or separate from impurities and foreign matter from the screenings. Vibrating screens are working with directed vibrations/amplitudes, which are selected on special product to screen, depending on the installation conditions. The screens can separate different fractions simultaneously. The choice of the screen size and dimension depend on the task. Advantages & benefits low operating costs, high operational safety, long service life good value for money compact design dust-proof design possible low wear different possible screening performance, depending on size and design different possible meshes and screen shapes possible different possible screen materials (PU, spring steel, stainless steel, wedge-wire screens, perforated plates, etc.) Construction The main components are: strainer with drive traverse strainers / cassette or tensioned version mechanism

Request for a quote

MIHLA INSAAT MALZEMELERI SAN VE TIC LTD STI

Turkey

Superior performance wedge dowel (carbon steel) for high static and seismic loads in cracked concrete Material, corrosion: Carbon steel, zinc plated Head configuration: External thread Approvals / test reports: ETA, FM (Factory Mutual), Seismic, Fire Features More economical, optimized dowel designs – wider embedment depth range, flexible edge and spacing allow more economical designs to be created using smaller base plates and façade brackets Faster and easier correct installation – no hole cleaning required (M8-M20) and ready for automatic pre-tensioning with Hilti Adaptive Torque tool (M8-M16) Design support available – use the PROFIS Engineering Software Suite to simplify steel-concrete connection design or contact your local Hilti Engineering Team for advice on more complex projects Easier inspections – head marking showing dowel type and length simplifies quality control after insertion

Request for a quote

SARTEX S.R.L.

Italy

Forged and hardened steel splitting wedge. Epoxy powder coating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

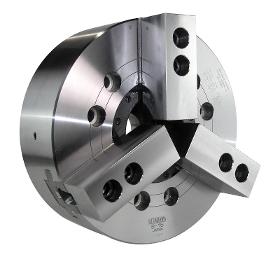

Compatible with large, readily available, range of jaws Allows for holding of larger components Upto 20% more speed and grip force than conventional chuck Standard Accessories AvailableKitagawa chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. These larger style chucks provide the higher grip forces required for doing large work. B series chucks are supplied with a blank drawnut as standard with a set of T-nuts.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compatible with large, readily available, range of jaws Allows for holding of larger components Upto 20% more speed and grip force than conventional chuck Standard Accessories AvailableKitagawa chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. These larger style chucks provide the higher grip forces required for doing large work. B-A series chucks are supplied with a blank drawnut as standard with a set of T-nuts and adaptor plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

The Worlds Most Popular Chuck Compatible with large, readily available, range of jaws Upto 20% more speed and grip force than conventional chuck Standard Accessories AvailableKitagawa's chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. These chucks are supplied with a spindle nose adaptor plate. B200A series chucks are supplied with a blank drawnut as standard with a set of T-nuts and an adaptor plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Larger Bore to Accept Larger Components down the Spindle Compatible with large, readily available, range of jaws Upto 20% more speed and grip force than conventional chuck Industry Standard Large Bore 3 Jaw Chuck Kitagawa's chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. The BB series has a big bore to accept larger components down the Spindle. BB200 series chucks are supplied with a blank drawnut as standard with a set of T-nuts.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Larger Bore to Accept Larger Components down the Spindle Compatible with large, readily available, range of jaws Upto 20% more speed and grip force than conventional chuck Industry Standard Large Bore 3 Jaw Chuck Kitagawa's chucks are manufactured from high grade alloy steel. Three jaw wedge style power chucks deliver up to 20% more speed, gripping force and bore size when compared to conventional chucks. The BB series has a big bore to accept larger components down the Spindle. BB200A series chucks are supplied with a blank drawnut as standard with a set of T-nuts and an adaptor plate.

Request for a quote

INTEGRA CABLE

Belarus

It is used for hanging flat optical cable on the supports of communication lines, power lines, light poles, between buildings and structures. It consists of an open housing with a ribbed contact surface, a wedge with an attached wire loop, and a «grater» — a perforated insert that is inserted between the cable and the wedge. The design of the clamp provides a firm hold on the cable. Product materials body, wedge, stainless steel insert, chrome steel hinge. It is recommended to be used for all sections of the cable route at practically any angles of its turn.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data Design Gate valve, with internal spindle, acc. to DIN 3352/4A, soft sealing, maintenance free. For the use of process water and wastewater. Features • The inside and outside surfaces of the valve are FBE-coated. • In case of leakage of the stem seals, the seals can be replaced under media pressure. • Low dead space and the flat valve seat guarantee a great flow characteristic and prevent product deposition. • Bidirectional pressure discharge. • Permission and marking acc. to directive 97/23/EG (Pressure Equipment Directive) Face to face EN 558-1 Row 14 (former DIN 3202 F4) Connection Flange DN40 … DN150, PN16 drilled, Flange DN200 … DN400, PN10 drilled. Flanges DN65 – PN16 will be delivered in 4-hole execution! Mounting position vertical preferred Pressure Range PN10 … PN16, see table Temperature Range 0°C … +80°C Material Body: GGG-50, FBE-coated Stem: Stainless steel Wedge: GGG-40/Brass/EPDM (NBR on request) Stem seals: EPDM (NBR) The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

The Neoarm series includes structural bearings of reinforced elastomer, consisting of an elastomeric block in which steel laminates hot vulcanized to the rubber are inserted on multiple laminates, with the main purpose of minimizing the swelling and slipping of the rubber under load. Neoarm structural bearings in general are used if the span of the beam does not exceed 20 m, if rotations are not extreme, if displacements are small and horizontal thrusts are limited. Nevertheless, they are sometimes made in large dimensions. By vulcanizing a wedge-shaped steel plate to the upper surface of the rubber, it is possible to install this type of bearing under beams of considerable slope. Notes: Even if elastomeric bearings are designed to consider shear movements, they should not be used to oppose permanent resistance against an external shear force applied on a constant basis. This means, for example, that they should be placed horizontally on the plane even if the deck is sloping. Please

Request for a quoteResults for

Steel wedges - Import exportNumber of results

14 ProductsCompany type