- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- straightening - steels and metals

Results for

Straightening - steels and metals - Import export

DOGA MAKINA

Turkey

We are able of producing a wide range of stainless steel flanges, including raised face socket weld, raised face threaded, raised face slip-on, stainless steel blind plate, stainless raised face blind, stainless lap joint, and stainless steel slide on plate. Stainless steel flanges with dimensions ranging from Ø 30 mm to Ø 740 mm are manufactured in accordance with your technical drawing requirements.

Request for a quote

ESTIMET SP Z O.O.

Poland

Takket være sitt erfarne team og moderne maskiner, kan ESTIMET realisere praktisk talt enhver jobb relatert til rulling av ark. Kanter av materialet som skal rulles foldes av oss tilsvarende. Dette reduserer mengden avfall. Vi kan innse rullingen av ark med atypiske former ved å bruke mikrosømmer på de kritiske punktene i materialet. Etter ferdigstillelse av rullingsprosessen fjernes mikrosømmene.

Request for a quote

ESTIMET SP Z O.O.

Poland

Laserskjæring av konstruksjons-, rustfrie, aluminium- og forzinket plater. Maksimal platestørrelse: 4000mm x 2000mm, tykkelse opptil 25mm.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Straightening press CDN400 with 3100x3000mm table and 1000mm stroke helps us finish our work with great precision.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our work starts with precise and efficient material cutting using modern machines. Our Laser and plasma cutters are available for sheet metal processing of all grades. Laser Trumpf 4kW with interchangeable table 4000x2000mm cuts mild steel of max. 18mm with both oxygen or nitrogen. Plasma Omnicut/Hypertherm where portal is also fitted with an acetylene burner; table size 6500 x 2000mm, usually cuts max. thickness 100mm

Request for a quote

GSW SCHWABE AG

Germany

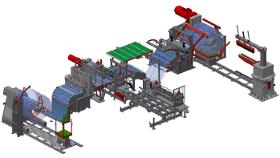

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

FÖHRENBACH GMBH

Germany

The straightening machine RM-1000 was developed for straightening deep-hole drills, as 4- and 6-axis version. The radial run-out of a drill is straightened using the 4-axis version. The 6-axis machine additionally corrects the camber of the shank and the head run-out of the soldered carbide drill bits. The maximum length of the drills is 1,000mm, the accuracy of the straightening process is 0.08 mm (depending on the work piece). An exportable straightening protocol is created for each straightening process. A robot cell is available as an option. Using this robot cell, the insertion and removal of the drills is performed. The robot cell is mobile and can be disconnected at any time in order to allow manual straightening processes.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

GSW SCHWABE AG

Germany

High quality, extremely simple operation, unreached price/performance ratio For decades, the GSW Straighteners are valued all over the world. The Straightener with clamshell head (the GSW “AlligatorHead”) came out in 1968 – the RMA series – and today is being built in up to 2000mm width. This machine levels coil set and equals out tension with up to 12mm thick materials. It has given GSW a pioneer’s position in the industry. The RMZ series Straighteners convince where high straightening and pull forces are needed. Its frametype head design provides a high stiffness and elevates this technology to work with high demands in straightening quality – even with highertensile materials.

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning aluminum part

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ESTIMET SP Z O.O.

Poland

Bøying av plater på numerisk styrte kantpresser, opptil knekkelinjens lengde (bøyingslenge) 5000mm

Request for a quote

ESTIMET SP Z O.O.

Poland

Böjning upp till 5000 mm x 225 ton Våra tryckbromsar har förmåga att böja upp till 5000 mm långa tryck med ett tryck på 225 ton med ett mycket rikt lager av böjverktyg som gör att du kan böja även mycket komplicerade element. Vi använder programvara för att beräkna utvecklingen från 3D-modeller. Våra maskiner är kompatibla med de flesta CAD-format. Pressbromsen är den viktigaste komponenten som krävs för att utföra plåtböjning. Det har vissa möjligheter och begränsningar. Böjverktyget (matris, slag) bestämmer också huruvida en given böjning kan göras. ESTIMET-företaget har ett mycket stort utbud av alla typer av böjverktyg. Tack vare detta kan vi inse även den mest ovanliga och krävande böjningen.

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Conventional cutting Cut using an industrial cutting machine and table, for cuts up to 6000mm x 3000mm (plasma for thicknesses up to 35mm and oxyfuel for thicknesses up to 200mm).

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

ILK IHRACAT AS.

Turkey

Our CNC bending service covers the following areas: Metal Part Bending: Bending metal sheets to the desired measurements and shapes. Design Compatibility: We offer customized bending services that match your technical drawings. Shaping and bending materials in industrial projects is a crucial step that defines the final design of a product. Through our CNC bending service, we guarantee the success of your projects by precisely and accurately bending metal sheets. Shape Your Projects Now! Bring your metal parts to the desired form with our CNC bending service. Complete your projects in the best way possible with our precision and accurate bending technology. Get a Quote and experience the difference! Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Multihole Steel Parts By CNC Turning, Milling, Boring, Tapping. Ming Xiao Mfg as a professional steel parts supplier from China Ningbo,we produce stainless steel parts,carbon steel parts,brass parts,aluminum parts & plastic parts for various indstries,especially pneumatic hydraulic parts, mechanical parts, furniture hardware parts, electrical & home appliance parts, construction use parts, vehicles parts, solar energy installation parts, lighting parts, etc. Such as tube coupling, hose coupling, shaft,Axis,pipe joint parts,hose connectors & transition connectors,copper machined tube, flange,bushing, Sleeve,knighthead,pedestal,Piston Rod,insert long pin, Dowel Pin,Drive Pin & Rod,ball head bolt,long rod machined parts,long thread tube parts,nonstandard thread bolt & nut,Extension Rod, etc. We custom Multihole Steel Parts Machining, CNC turned & holes bored parts,welcome contact us to discuss about your projects.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener feeder machine with compact single body and for working precision feeding and without damage on sheet metal surface. Our coil straightener feeder machines provide to have working possibility with high speed and precision sheet metal feeding and straightening results during press feeding. We have as alternative for coil straightener feeder machine standard models. And we design and provide for different request specific coil feeder straightener machines. We supply our coil feeder straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener feeder machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener machine for having perfect straightening results and without damage on sheet metal surface. Our coil straightener machines provide to have working possibility with high speed and precision sheet metal straightening results during press feeding. We have as alternative for coil straightener machine standard models. And we design and provide for different request specific coil straightener machines. We supply our coil straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener machine solution.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining. Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces. More info https://eurobalt.

Request for a quoteResults for

Straightening - steels and metals - Import exportNumber of results

54 ProductsCountries

Category

- Bending - steels and metals (19)

- Steels and metals - machining (17)

- Metal straightening machines (14)

- Turning - steels and metals (11)

- Cutting - steels and metals (8)

- Milling - steels and metals (8)

- Straightening - steels and metals (5)

- Steel & Metals (4)

- Grinding - steels and metals (3)

- Sintering - steels and metals (3)

- Forming - steels and metals (2)

- Pipes and tubes, stainless steel (2)

- Boring - steels and metals (1)

- Finished Metal Products (1)

- Folding - steels and metals (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)

- Perforation of steels and metals (1)

- Shaping - steels and metals (1)

- Shearing - steels and metals (1)