- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical operations

Results for

Mechanical operations - Import export

CIC - KLAUS CZERWONKA

Germany

Mechanically operated valves with button and roller lever with full aluminum. The sturdy aluminum construction ensures strength and durability. Available in 1/8″ sizes and features 3/2 and 5/2. Other sizes on request.

Request for a quote

NORELEM FRANCE

France

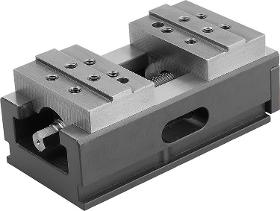

Body and jaw holder hardened and ground. Note for ordering: Supplied with hexagon crank handle. Order jaw plates separately. Note: Mechanically operated centric vice. Suitable for automation: prepared with gripper slot for handling systems. Flexible mounting: suitable for zero-point systems, mounting on machine tables or on custom systems via a baseplate. Centring precision: +/- 0.02 mm. The use of a torque wrench is recommended to achieve a controlled clamping force. Features: Clamping slide and spindle nut in one piece Slots and fastening threads for mounting attachment jaws Reversible jaws (accessories) with lateral thread for workpiece stop enables a wider clamping range Good swarf and coolant removal

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

De Smet Engineers & Contractors has been involved in all steps of the production of vegetable oils from oilseeds crushing for the construction of Edible Oils Plants; in this article you will find a more detailed understanding about the process of vegetable oil extraction: First step: Preparation of the oil containing material prior to solvent extraction Cleaning and Drying The plant feedstock must be cleaned so that foreign matters are removed. This applies particularly to sand/silicate and iron which may damage the preparation plant equipment. For some seeds or for some processes the incoming material moisture must be controlled and adjusted for better efficiency of subsequent operations. Mechanical preparation Most of raw materials needs to broken to reduce the particle size to ensure proper cooking and flaking. They are then heated in cooking / conditioning equipment and their moisture further controlled in addition to be softened before the next mechanical operations. After cooking, heated grits are flaked so that the oil cells are broken and the oil more readily available for further solvent extraction or mechanical pressing. Pressing Oilseeds containing above 20 to 25% (rapeseed, sunflower seeds, cottonseeds...) are generally pressed mechanically in order to extract most or part of the oil available in the feedstock. This operation is done through full pressing for maximum oil recovery leaving up to 5 to 10% in the final cake which is marketed as such or through a low pressure pre-pressing operation producing a cake with higher residual oil content which is then recovered in the solvent extraction plant. Dehulling Oil extraction plants produce a solid finished product in addition to the extracted oil; this product (cake or meal) is normally used as an important component for animal feed recipes. Depending on the meal destination, its protein content often needs to be increased and its fibre content minimized. Such characteristics are generally achieved through decortication or dehulling operations that separate the outer part of the feedstock before extracting the oil. Second step: Solvent extraction of the material suitably prepared Extraction In the solvent extractor, solids (Flakes from the flaking machines or cakes from the pre-presses) are conveyed through the equipment while a mixture of hexane and oil (miscella) is sprayed counter-current. The extractor produces therefore deoiled solids containing solvent and miscella. Desolventization Deoiled solids coming out of the extractor are conveyed to a dedicated equipment that completely removes the remaining solvent while preserving the meal quality: the desolventizer. This apparatus is usually combined with additional sections for drying and cooling the meal to the required storage and market parameters. Miscella distillation Solvent contained in the miscella is completely removed under vacuum and optimum temperature for preserving oil quality. The solvent from the distillation as well as the one removed at meal desolventization stage are then recycled to the extractor. Solvent recovery Since the air entering the process together with material fed to the extractor is laden with solvent when it is removed from the plant it first pass through a specially designed absorption column to limit emission to an acceptable level. Meal treatment The extracted meal is often subject for further treatment, including grinding to obtain the required granulometry or pelletizing to reduce its volume during transport.

Request for a quote

CARONI S.P.A.

Italy

Patent pending n. 01830710.8. Double productivity One machine does it all! Mow & Carry® is the mower that cuts, sucks up, gathers and dumps grass directly in the trailer of a vehicle. Compact and light, fast and safe with any tractor, Mow & Carry® doubles productivity while halving time and costs. CUT AND GATHER IN A SINGLE PASS While it mows, Mow & Carry® sucks up and gathers the grass in a container fitted on top of the mower: all with a single machine and in a single pass! A suction turbine system on the side outlet of the machine – which is driven by the shaft of one of the blades – coveys the cut grass into the collecting container, which then dumps the grass in the trailer of a vehicle. HANDY DUMPING SYSTEM When the container is full, simply operate the hydraulic distributor of the tractor to dump the grass directly in the trailer of a vehicle or on the disposal site. The container is lifted, moved and tipped thanks to a lever-system mechanism operated by three synchronized hydraulic cylinders. The container is dumped 140/180 cm from ground level. HALVED TIME AND COSTS By combining cutting and gathering operations, Mow & Carry® doubles cutting speed, effectively halving labour costs and saving on the purchase of machinery. In addition, fuel consumption is lowered because there is a step less and because of the contained weight of the mower. Naturally, lower fuel consumption also means lower polluting emissions. WHEN SAFETY AND LIGHTNESS GO HAND IN HAND The TR150-600L and TR180-750L mowers only weigh 941 and 1032 lbs, respectively. The light plastic grass container maximizes manoeuvrability and visibility from the tractor. Particular attention was paid to the setup during dumping to guarantee the perfect stability of the tractor. REVOLUTIONIZING TRADITIONAL STRENGTHS With its revolutionary design, Mow & Carry® also offers all the advantages of Caroni’s traditional quality. Particularly suitable for large and medium surfaces – sports fields, parks, golf courses, etc. – it can be fitted onto any tractor with a simple fastening operation. A clean cut is assured by the 150 or 180 cm long mower, which is equipped with three blades with a vertical shaft and side dumping. Eight swivel wheels make progress on a grassy area easy and light. Eight swivel wheels make progress on a grassy area easy and light. To adjust the cutting height, simply move the spacers mounted on the fork shaft; the third “floating” point and the lower tractor fastening points, which were designed to allow an oscillation of 45°at most, enable the machine to follow the contour of the ground perfectly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mechanical operations - Import exportNumber of results

4 ProductsCountries

Company type