- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- supply vessels

Results for

Supply vessels - Import export

METZEN INDUSTRIES GMBH

Germany

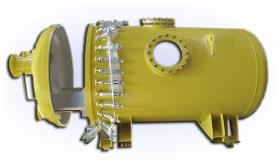

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Busbar and circuit breaker vessel and containers in various designs Welding Full dimension check Mechanical engineering Pressure testing Leak testing with SF6 gas Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

We support you throughout your design process and consider all the necessary technical requirements for welding. We can also produce components and assemblies from scratch. METZEN supports you with everything from purchasing materials to welding, mechanics, required checks and authorisations, surface treatment and, finally, documentation. Our product range includes normal steel vessel construction, stainless steel vessel construction/stainless steel pressurised vessel construction and aluminium vessel construction.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELVION HOLDING GMBH

Germany

A Box Cooler is a vessel water cooling system. It comprises a U-tube bundle that is fitted in the sea chest on the side of a vessel, saving space in the engine room. The sea chest is equipped with inlet and outlet grids. Cooling sea water enters through the inlet grid and flows along the U-tube bundle to the outlet grid, thus cooling the water inside the tubes. The cooling effect is achieved by the forced circulation of sea water when the vessel is moving or by natural convection when it is stationary. Box coolers can be used for a wide variety of temperature-reducing duties on a vessel, from cooling the main engines, auxiliary engines and bow thrusters to air conditioning and hydraulic systems. Kelvion Box Coolers are ideal for small and medium sized vessels, including for example: tugboats, barges, fishing boats, carriers, dredgers, supply vessels, ferries, ice breakers, cargo freighters, tankers and reefers.

Request for a quote

EUROPEM

Belgium

Europem can supply complete flare systems which include knock-out vessels, water seals, molecular seals, conical purge gas seals, pilots and ignition systems. Additionally, Europem has developed a unique ATEX zone O vapour extraction system for use in conjunction with VRU’s, combustors, flares and thermal oxidisers. Vessels Europem supplies the upstream equipment to remove droplets from gases or provide a seal between the flare burner and the waste gas piping in order to prevent air from infiltrating the flare riser and thus prevent flash back. Purge gas is employed to prevent flash back by stopping air ingress to the flare gas header. Molecular seals and also Conical seals are both devices that reduce purge gas flow rates. Conical seals will require a slightly higher purge gas flow rate than a Molecular seal, but have the advantage of a simpler more economic design. This design cannot be blocked by debris, sludge or ice formation and does not put additional load on the flare structure, being integral to the flare riser. Although purge systems are the perfect solution for flash back prevention, the flow of purge gas can always be lost. A water seal can be installed to provide the ultimate barrier to flame propagation upstream in the waste gas piping. Vessels can be supplied either as an integral part of a flare system or as stand alone items. Both vertical, typically integrated with the Flare riser, or horizontal configurations are available. Features Water Seal Vessels equipped with an overflow weir to maintain a minimum water level, anti-pulsation baffles and a dip-pipe with distribution cone forcing the waste gas to flow through the water bath. Molecular Seals are equipped with a riser pipe and cap to either form a layer of purge gas on the top, when the purge gas is lighter than the air, or on the bottom when the purge gas is heavier than the air of the vessel Conical Seals are in fact an inverted conical restriction made as a section of the riser. This restriction will locally induce a higher waste gas velocity which in turn entrains any penetrating air and carries it up to the flare burner. Knock Out Drums contain packing to separate droplets from the waste gas. A liquid level control with automatic purging prevents the vessel from overfilling. Models EP-WS Water Seal Vessel EP-MPRS Molecular Purge Reduction Seal EP-CPRS Conical Purge Reduction Seal EP-KOD Knock-Out Drum

Request for a quote

LASEST (LASMEDTECH LLC)

Russia

The Nd YAG Arthro LASEST laser module is designed to affect deep localized joint pathologies. Photothermal and photomechanical processes that occur in tissues when exposed to Nd YAG Arthro radiation provide the synthesis of extracellular matrix molecules, the regeneration of connective tissue cells, and the organization of the endothelium. The high effectiveness of Nd YAG Arthro LASEST exposure is due to a number of therapeutic effects that occur under the influence of laser radiation – Antiinflammatory effects due to the expansion of the supply vessels and accelerate the flow of oxygen and other substances to damaged tissues. – Analgesic effects due to a deep effect on pain receptors and stimulation of the formation of extracellular matrix.

Request for a quote

FLEXIND B.V.

Netherlands

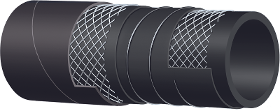

Reinforcement High tensile strength textile cords and embedded steel spiral wire antistatic wire. Outer wall Black conductive CR abrasion, ozone, hydrocarbon and fire resistant. Application Transfer of fuel, oil and sludge from supply vessels to offshore platforms. Also suitable for pumping seawater and barite transfer. Also available in self floating version. Reserve buoyancy calculated according to GMPHOM 2009 standard. End load tensile resistance ID 2" 2,000 kg ID 3" 4,000 kg ID 4" 7,000 kg ID ≥ 5" 10,000 kg ABS Type Approved Hose Assemblies. Electrically continuous.

Request for a quote

GASTRO - HAAL, S.R.O.

Slovakia

This electric pan is designed for preparing different meals and dishes. Food is thermally processed – by frying in oil or stewing with water. The pan may be used in large-scale kitchens, factory canteens or buffets. The unit is made of food safe stainless steel. The upper part of the appliance contains a cooking vessel whose cover is attached to the support frame and placed on slide bearings. The cooking vessel may be manually tilted using a turning wheel on the right side of the appliance. The pan is fitted with a working thermostat under the front cover in the electric box fastened to the support frame. On the back of the support frame is a proximity switch which disconnects the control circuit when the vessel is tilted. The electric pan is fitted with heater body located on the pressure plate under the cooking vessel, with electrical water supply into boiling vessel and with adjustable feet to accommodate uneven floors.

Request for a quoteResults for

Supply vessels - Import exportNumber of results

11 ProductsCompany type