- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- synchronous belt

Results for

Synchronous belt - Import export

ERO JOINT .TANALS

France

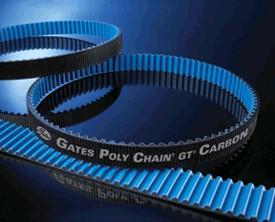

In addition to providing a high quality and technology in drive solutions, Gates also provides you expertise on synchronous drive systems. The Poly Chain® GT Carbon™ is the new polyurethane synchronous belt by Gates, manufactured with patented carbon tensile cord and providing a high torque and low speed drives. Engineers from the materials development department of Gates are the pioneer in high fatigue-resisting carbon fibre tensile cord incorporated into a new polyurethane compound belt. Then the Poly Chain® GT Carbon™ is the most potent synchronous belt in the transmission world, and provide a maintenance-free, energy saving and eco-friendly operation. It is a brilliant substitute to roller chain and gear drives.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The wall-mounted system feeds the machine and retracts, facilitating the feeding of machine tools where obstructions to protective doors must be avoided. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The compactness of the closed system makes it ideal for environments without much space between the machine and the ceiling. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing pulleys can be made of such different materials as aluminum, steel, stainless steel, gray cast iron or plastics. The fact that they can be produced with all pitches and designed according to your specifications and drawings ensures an optimal solution for any application. Our synchronizing pulleys work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifications. Special surface coatings, such as hard coating, anodizing, zinc coating, bronzing, improve the corrosion and wear resistance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

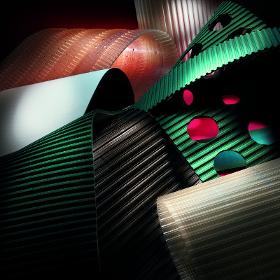

Keiper PU wide timing belts are made of abrasion-resistant polyurethane and high-strength aramid cords in widths up to 600mm. These timing belts are specially designed for synchronous transport applications. In view of the production width as well as outstanding mechanical and chemical properties, they can be used for many applications. Moreover, it is possible to use special materials such as, for example, polyurethane that is suitable for contact with foodstuffs, or a nylon coating on the tooth facing and back side. Properties and special features: High-strength aramid tension cords Parallel arrangement of tension cords for even distribution of tension Form-fit, synchronous running Low-noise, high abrasion resistance and flexibility Applications: As a substitute for transport belts for synchronous positioning Applications in the foodstuffs industry Sausage, meat and cheese processing Conveying of bulk goods

Request for a quote

STATEC BINDER GMBH

Austria

The high-performance high-level palletizer PRINCIPAL-H is capable of palletizing up to 2400 bags or cartons per hour. The fast high-level palletizer is equipped with an empty pallet magazine and an outfeed system. A bag flattener at the beginning ensures that the bags are “in shape” for stacking. Flexible layer patterns are made possible by a servomotor-driven overhead rotating device that rotates the bags to the required position. For example, the bags can be positioned so that the bag seams point inwards or barcodes can be read from the outside. A well-structured layer pattern is guaranteed by the synchronous belt drive of the layer pusher, which enables the exact positioning of the bags or boxes, and the motor-driven front and side shifters, which ensure a stable and right-angled layer.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Synchronized transmission and drive by gear with one belt. The change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours, its maintenance is easy and maintain is simple, so it doesn’t influence production. 2.Cutter head unit: The new style cutting knife droved by servo motor, with high speed, more stable and precise, shrinks perfectively.Synchronous locating device enables the tolerable error to ±1mm.Unit cutter head plane design in China which applies to the container of D30mm—D130mm.You never need to change or debug it. Cutter head original transducer is inside the cutter head and when you take down cutter head, you do not need to correct the synchronous belt. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products. 3. Label feeding unit: Single material shelf with

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Flat surface plane labeling machine can work for all kinds of objects with plane, flat surface, side surface or large curvature surface such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc.Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries. It has optional date coding device, realize date coding on stickers. Features You Can Not Ignor: 1. It can label for any products with flat surface. More flexible arrangement for manufacturing schedule. 2. The labeling head convenient to adjust, the labeling speed is automatically synchronous with the conveyor belt speed to ensure precise labeling. 3. The speed of conveyor line, the speed of pressure belt and the speed of label output can be set and changed by the PLC human interface. 4. Use famous brand PLC, stepping or servo motor, driver, sensor, etc, good quality components’ configuration.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp has developed the energy-ecient drive system EcoDrive for the ContiRoll® main drives. This system meets tomorrow’s legal and standard demands on the energy eciency of drive systems already today. It comprises frequency converters, motor and gearbox - all well-tuned to one another. In addition to the energy eciency our R&D-work focussed on an improved precision and controllability of the entire drive system. The focus is on high belt speeds, precise r.p.m. for a synchronous operation of the steel belts, torques adjusted to the characteristic load line in connection with the hydraulic pressure/position control, good performance, good uptimes and ease of maintenance. This corresponds to the demand on a very high product quality and an on-demand energy consumption even in partial load operation. This new drive system is able to save more than 10 % of the electrical drive energy compared to traditional Solutions.

Request for a quote

DAVALL GEARS LTD.

United Kingdom

Davall supply all forms of timing [synchronous] belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized distributor divides the stream of products batch-by-batch and gently into two lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. The compact design permits simple incorporation into existing lines. Technical data Distribution: 2 lanes Distribution process during continuous flow of materials Product gap: from 5 mm Conveyor speed: more than 60 m/min. Lane distance: 110 mm, 130 mm Complete machine cover made of Makrolon with maintenance doors Independent electrical control system with congestion monitoring Installation length: 1200 mm Optional equipment Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized switch divides the stream of products batch-by-batch and gently into several lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. Because the number and width of the lanes to be approached can be freely selected, the machine is suitable as product feed for palletizing machines or similar devices. Technical data: —Distribution: Number of lanes depends on the recipe —Distribution process during continuous flow of materials —Product gap: from 15 mm —Conveyor speed: more than 60 m/min. —Lane distance: depends on recipe —Complete machine cover made of Makrolon with maintenance doors —Independent electrical control system with congestion monitoring Optional equipment: —Loading and unloading belts —Infinitely variable width adjustment

Request for a quoteResults for

Synchronous belt - Import exportNumber of results

14 ProductsCompany type