- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolls

Results for

Rolls - Import export

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

In respect of rolling the serration type working pieces as the transmission shafts of autobobile/motor-vehicles, spline shaft, and manual tools. The grinding type serration spline rolling dies can be ensured for the precision, delicate and smooth surface, extending the life of the rollers.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Most Asian countries have their own flavor of spring rolls. Spring rolls from each country look alike, but are different in their ingredients or appearance. Spring roll is a traditional snack in China. They are made of a thin dough filled with fillings and fried. Fillings and sizes vary from place to place, but they are basically flat tubes. In China, for example, most people use vegetables and meat as fillings, while in some northern areas they use red bean paste instead. In Malaysia and Singapore, spring rolls are called popiah. Inside the Popiah there is sauce, vegetables and garnish. The crust is first coated in sweet or hot sauce, then the ingredients are added. Spring rolls are also a popular dish in Vietnam. The difference between Vietnamese spring rolls and Chinese spring rolls is that the skin of the spring roll is not made with wheat flour but with rice flour. They can be eaten in two ways: fried or unfried, wrapped with lettuce leaves and dipped in sauce.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

Product ID: UM-50H

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-35H thread rolling machine is a special designed for serration type working pieces. UM-35H thread rolling machine is setting up with horizontal movable center-seat to roll the serration type working pieces . To ensure steady teeth shape, concentricity of work-piece and vertical degree. UM-35H thread rolling machine manufactured as required by customers, majored with thread rolling machines and minored with the supporting tools Take the inquiry from customers with offering the thread rolling machines, such as the character thread rolling, the roundness thread rolling, grooving thread rolling. A straight knurling, and diamond pattern knurling etc.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

For the mass production of fastener screws, it may also another good choice for the flat type thread rolling which may reduce production cost, applied to big-valume production. With the same named tool steel SKD11 (JIS) and SKH9, together with advanced heat treatment technology, and thread grinding CNC machien to offer the customer for another choice.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The knurling die: The knurling pattern with non-skid and attracting in appearance on manual tools (straight knurling pattern or diamond knurling pattern) by the knurling dies. The knurling pattern is formed by gear hobbing machine before the heat treatment process, the precision is less good as the grinding type, but, the straightness, and concertricity can be assured.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

In respect of rolling the serration type working pieces as the transmission shafts of autobobile/motor-vehicles, spline shaft, and manual tools. The grinding type serration spline rolling dies can be ensured for the precision, delicate and smooth surface, extending the life of the rollers.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

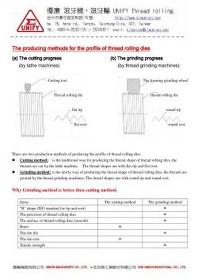

Specification: There are 2 producion methods of producing the proflie of thread rolling dies: Cutting method: is the traditional way for producing the thread shape of thread rolling dies, the threads are cut by the lathe machine. The thread shapes are with flat tip and flat root. Grinding method: is the newly way of producing the thread shape of thread rolling dies, the threads are ground by the thread grinding machines, teh trhead shapes are with round tip and round root. Why we choose the grinding method for UNIFY thread rolling dies, please check the above for the reason. Currently, we have more then 10 units of REISHAUER thread grinding machines (Swiss made) in our factory. The thread rolling dies offered by UNIFY are always the grinding type. The higher level quality can be ensured!

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

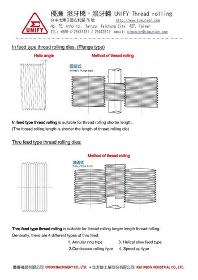

In feed (Plunge) thread rolling dies: There are multiple starts (helix angle) at the edge of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling of shorter length. the thread rolling progress as: Place a work piece in between of thread rolling dies, the screws are formed by strongly pressing progress, when the right thread rollign die returns, take out the work piece. (the work piece stays at the same rollng point). Thru feed thread rolling dies: The threads are as the rings on the surface of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling longer length of screws. (longer then the length of thread rolling dies) The threading progress as: Set the helix angle with the roller shafts of thread rolling machines first, and insert the thread rolling dies. 1. Place a work piece in between of thread rolling dies, make sure the work piece is clamped by thread rolling dies. 2. The work piece is moving

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-3D set with the vibration feeding bowl which is suitable for thread rolling set screws, wooden thread screws, and any less short screws are suitable. It is a very good method for saving labor cost.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-16 hydralich thru feed thread rolling machine set with the long bar feeding syste, this say up-grade the capacity, and save the labor cost.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The robotic arms are setting in the between of UM-50A thread rolling machine.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

Specially designed for tubular processing. Equilateral triangle supports running to assure the roundness. Equilateral triangle supports rolling for improving roundness, concentricity and vertical degree. Driving by hydraulic unit: Featuring in easy operation and powerful pressure. The transmission gear with grinding shape: Featuring in noise-free, durable and precise transmission. Particularly applied to the tubular thread processing, such as oil connectors, bicycle, automobile and motor vehicle parts, radiating pipe etc.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-3DX 3-die thread rolling machine is specially designed for tubular processing. Equilateral triangle supports running to assure the roundness. with 3- die thread rolling machine is with equilateral triangle supports the thread rolling for improving roundness, concentricity and vertical degree. UM-3DX thread rolling machine is driving by hydraulic unit: Featuring in easy operation and powerful pressure. UM-3DX is set with 4 speeds transmission gear with grinding shape teeth: Featuring in noise-free, durable and precise transmission. Particularly applied to the tubular thread processing, such as oil connectors, bicycle, automobile and motor vehicle parts, radiating pipe etc.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-3DL 3-die thread rolling machine is specially designed for tubular processing. Equilateral triangle supports running to assure the roundness. 3-die thread rolling machine is with equilateral triangle supports the thread rolling for improving roundness, concentricity and vertical degree. UM-3DL thread rolling machine is driving by hydraulic unit: Featuring in easy operation and powerful pressure. UM-3DL is set with 4 speed transmission gear with grinding shape teeth: Featuring in noise-free, durable and precise transmission. Particularly applied to the tubular thread rolling processing, such as oil connectors, bicycle, automobile and motor vehicle parts, radiating pipe etc.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

Designed for the thread rolling of standard screws, bicycle parts, automobile parts, small household electric appliances and various and various machinery parts. The precise worm shaft and worm gear: Keep steady transmission, and the accuracy of thread profile. Precise transmission grinding type gear shape: Noise-free, durable, transmission operates precisely, and no extra space when transmission. dove tail-type slide: assuring that jumping, vibration, and wear will not happen during rolling process. UM-3 adopts eccentricity feeding: Featuring easy operation and smart design, suitable for small screws and knurling patterns.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIFY THREAD ROLLING

Taiwan R.O.C.

Feature: UM-35 thread rolling machine is suitable to roll standard screws, bicycle pats, automobile arts,.....and various machinery parts. UM-35 thread rolling machine is equipped with the precise work shaft and work gear which keep the steady transmission, and the accuracy of thread profile. UM-35 thread rolling machine is with the precise transmission grinding type gear shape, therefore, noise-free, durable, precisely, and no extra space when transmission are able to be ensured. UM-35 thread rolling of the dove tail-type slide for assuring that jumping, vibration, and wear will not happen during rolling progress.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The features of UM-16 thread rolling machine: Thru feed and in-feed (plunge feed) both available: The rolling time and the rolling length can be adjusted by the sensors. Powerful rolling pressure : The slide way feeding is driven by hydraulic unit, precision in positioning, owerful without any distortion. Solid structure: heat treatment of high tension cast iron FC-25 frame is durable Steady feed motion: Ground square slide way can avoid the jumping , vibration and wear away. Perfect transmission: The ground-thread worms with heat treatment progress can be matched completely and smoothly with phosphoric brone worm gears. Specially suitable for: Long length screws, ACME screws, Ball Screws, machine parts, tool and automobile / motorcycle parts.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The features of UM-30 thread rolling machine: Thru feed and in-feed (plunge feed) both available: The rolling time and the rolling length can be adjusted by the sensors. Powerful rolling pressure : The slide way feeding is driven by hydraulic unit, precision in positioning, owerful without any distortion. Solid structure: heat treatment of high tension cast iron FC-25 frame is durable Steady feed motion: Ground square slide way can avoid the jumping , vibration and wear away. Perfect transmission: The ground-thread worms with heat treatment progress can be matched completely and smoothly with phosphoric brone worm gears. Specially suitable for: Long length screws, ACME screws, Ball Screws, machine parts, tool and automobile / motorcycle parts.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-75 hydraulic thru feed type thread rolling machine is the biggest model in our factory currently. The controlling of UM-75 is with PLC program and HMI systems. It is easier for the step adjustments as required. The features of UM-75 thread rolling machine: Thru feed and in-feed (plunge feed) both available: The rolling time and the rolling length can be adjusted by the sensors. Powerful rolling pressure : The slide way feeding is driven by hydraulic unit, precision in positioning, owerful without any distortion. Solid structure: heat treatment of high tension cast iron FC-25 frame is durable Steady feed motion: Ground square slide way can avoid the jumping , vibration and wear away. Perfect transmission: The ground-thread worms with heat treatment progress can be matched completely and smoothly with phosphoric brone worm gears. Specially suitable for: Long length screws, ACME screws, Ball Screws, machine parts, tool and automobile / motorcycle parts.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The superior tool steel is a very important element of thread rolling dies. SKD11 (JIS) and 1.2379 (DIN) are the named raw material which we have chosen for the past years. The blank of thread rollingd ies are heat treated by Japanese TECHNO vaccum & oil quenching furnace by heat treating dep. (TOYOGEN INDUSTRIAL CO.,) It will render the higher rigidity and higher wear-resistance of thread rolling dies. After the heat tratment progress, the thread rolling dies are ground by Swiss REISHAUER thread grinding machines. And another progress of tempering to reduce the grinding stress is necessary for thread rolling dies. The thread rolling dies are ready for sale after the quality exam. The good quality of thread rolling dies is able to offer higher precision, longer working life, and reduced the cost to customers. We also produce the thread rollingd ies for other brands thread rolling machines. Your special specifications and requirements are very welcomed.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The features of UM-50 / 50A thread rolling machine: Thru feed and in-feed (plunge feed) both available: The rolling time and the rolling length can be adjusted by the sensors. Powerful rolling pressure : The slide way feeding is driven by hydraulic unit, precision in positioning, owerful without any distortion. Solid structure: heat treatment of high tension cast iron FC-25 frame is durable Steady feed motion: Ground square slide way can avoid the jumping , vibration and wear away. Perfect transmission: The ground-thread worms with heat treatment progress can be matched completely and smoothly with phosphoric brone worm gears. Specially suitable for: Long length screws, ACME screws, Ball Screws, machine parts, tool and automobile / motorcycle parts.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The features of UM-40 thread rolling machine: Thru feed and in-feed (plunge feed) both available: The rolling time and the rolling length can be adjusted by the sensors. Powerful rolling pressure : The slide way feeding is driven by hydraulic unit, precision in positioning, owerful without any distortion. Solid structure: heat treatment of high tension cast iron FC-25 frame is durable Steady feed motion: Ground square slide way can avoid the jumping , vibration and wear away. Perfect transmission: The ground-thread worms with heat treatment progress can be matched completely and smoothly with phosphoric brone worm gears. Specially suitable for: Long length screws, ACME screws, Ball Screws, machine parts, tool and automobile / motorcycle parts.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-16 Thread rolling machine is setting with the vibration bowel. The working pieces are feeding to the between of the two thread rolling dies, after the thread rolling process, the working pieces are automatically loading off from the UM-16 thread rolling machine.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

"Work piece diameter(mm) Ø6 ~ Ø50 Pitch(mm) 0.8P ~ 6.0P, M:0.3 ~ M:1.5 Length of thread rolling(mm) 98MAX Spindle speed 15, 20, 30, 45, 60, 70 r.p.m Thread rolling die(mm) Diameter Ø200MAX Bore Ø70 Length 35,70,100 Keyway 14 X 7 Distance of the rolling spindles(mm) 155 ~ 255 Output (pieces/min) 4 ~ 15 Main power motor 10 HP 6P (7.5 kw) Hydraulic motor 5 HP (3.7 kw) Max rolling pressure 40 TONS Net weight 4050 kgs Gross weight 4450 kgs Overall dimension 1900 x 2300 x 2300 mm Shipping measurement 1800 x 2300 x 2250 mm"

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm) Ø18 ~ Ø60 Axial pitch for ISO threads(mm) 1.0P ~ 6.0P Length of thread rolling(mm) Plunge rolling(In feed):48 Thru feed rolling:no limited Spindle speed 220、350、580、720r.p.m Thread rolling die(mm) Diameter Ø120 Bore Ø40 Length 25,50 Keyway 8 X 4 Distance of the rolling spindles(mm) 105 ~ 190 Output (pieces/min) 4 ~ 25 Swivel of roll-axis ± 3° Main power motor 5HP 6P(3.7kw) Hydraulic motor 3 HP (2.2 kw) Max rolling pressure 12 TONS Net weight (Approx.) 1300 kgs Gross weight (Approx.) 1450 kgs Overall dimension (L x W x H) 1600 mm x 1500 mm x 1600 mm Shipping measurement (L x W x H) 1450 mm x 1400 mm x 1700 mm

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Thread rolling machines are used to produce screws, bolts, and tools. The blank is pressed by thread rolling dies which are attached to the thread rolling machine . The Cam type thread rolling machine is adopted the mechanical cam feed to complete the thread rolling motion, and the precise feed positioning can be ensured. Feature: UM-35 thread rolling machine is suitable to roll standard screws, bicycle pats, automobile arts,.....and various machinery parts. UM-35 thread rolling machine is equipped with the precise work shaft and work gear which keep the steady transmission, and the accuracy of thread profile. UM-35 thread rolling machine is with the precise transmission grinding type gear shape, therefore, noise-free, durable, precisely, and no extra space when transmission are able to be ensured. UM-35 thread rolling of the dove tail-type slide for assuring that jumping, vibration, and wear will not happen during rolling progress.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm)Ø10 ~ Ø75 Axial pitch for ISO threads(mm) 1.0P ~ 10.0P Length of thread rolling(mm) Plunge rolling(In feed):148(75A:200) Thru feed rolling:no limited Spindle speed 20 ~ 50 r.p.m variable speed Thread rolling die(mm) Diameter Ø200(75A=Ø250)MAX Bore Ø70(75A= Ø85) Length 35,70,100,150(75A=70.100.150.200) Keyway 14X7(75A=18X9) Distance of the rolling spindles(mm) 275 ~ 195(75A:300~220) Output (pieces/min) 4 ~ 20 Swivel of roll-axis ± 6° Main power motor 25 HP (18.75 kw)(75A=30HP) Hydraulic motor 7 1/2 HP (5.5 kw)(75A=10HP) Max rolling pressure 60 TONS Net weight (Approx.) 4,700 kgs Gross weight (Approx.) 5,200 kgs Overall dimension (L x W x H) 2,600 mm x 2,400 mm x 2,400 mm Shipping measurement (L x W x H) 2,520 mm x 2,240 mm x 2,230 mm

Request for a quoteResults for

Rolls - Import exportNumber of results

30 ProductsCountries

Company type