- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thickness measurement equipment

Results for

Thickness measurement equipment - Import export

CYGNUS INSTRUMENTS LTD

United Kingdom

As the top of the surface thickness measurement instruments range, the Cygnus 6+ digital thickness gauge has a bright colour LCD display AND an endmounted rotatable LCD display, and is Cygnus’ most advanced material thickness gauge. This unit offers a range of key features for the professional user, such as Ascan and Bscan displays to help verify readings while MSI™ indicates stable readings; comprehensive data logging with three available formats; enabling hasslefree reporting and analysis; manual and automatic gain control; Bluetooth connectivity; plus much more. As well as the multipleecho measuring mode for accurate and reliable measurements through coatings up to 20 mm thick, this unit also uses singleecho and echoecho modes for extreme corrosion and back wall pitting. s 6+ PRO is an excellent choice when looking for a NDT thickness gauge.

Request for a quote

CYGNUS INSTRUMENTS LTD

United Kingdom

The Cygnus 4 General Purpose ultrasonic thickness gauge is ideal for most industrial, shipping and structural inspection applications. The unit is extremely userfriendly thanks to its simple to use keypad, intuitive menus and a colour LCD display which can be viewed in all lighting conditions. Using the trusted Cygnus multipleecho technique, the Cygnus 4 ultrasonic thickness gage is used for measuring metal thickness through paint (up to 20 mm thick) providing an ultrasonic thickness measurement that is accurate and reliable. Certified to US MIL STD 810G standard, this throughcoating ultrasonic thickness gauge offers maximum strength and environmental protection (IP67).

Request for a quote

CYGNUS INSTRUMENTS LTD

United Kingdom

The Cygnus 2+ metal thickness gauge has an endmounted rotatable display designed for rope access work, providing a safer environment when working at height. As with all Cygnus thickness measurement instruments, the Cygnus 2+ uses the multipleecho mode for measuring through thick coatings (up to 20 mm thick in Deep Coat mode). As well as this, the Cygnus 2+ thickness gauge also incorporates the singleecho mode for measurements on uncoated surfaces with heavy front face and/or backwall corrosion, and the echoecho mode for measurements on painted metals with heavy back wall corrosion and pitting using a variety of portable UTM probes. Offering maximum strength and environmental protection, the Cygnus 2+ metal thickness tester is certified to stringent US MIL STD 810G standard and IP67.

Request for a quote

CYGNUS INSTRUMENTS LTD

United Kingdom

Specifically designed for divers undertaking ultrasonic thickness measurement (UTM) of underwater structures. The Cygnus Underwater diver-held ultrasonic thickness gauge has been built to withstand harsh subsea environments while providing quick and accurate metal thickness measurements through coatings or heavy corrosion. This diver-held thickness gauge is simple to operate using 3 function keys, an intuitive menu and a large LCD display – highly visible, even in low-visibility waters.

Request for a quote

CYGNUS INSTRUMENTS LTD

United Kingdom

Within the thickness measurement instruments range is the Cygnus Mini ROV Mountable ut thickness gauge. This gauge is pressure tested to 500m and designed to be mounted onto small observation ROVs with or without a manipulator facility, allowing the operator to carry out thickness measurements in areas that have previously been unfeasible using large ROVs or divers. Supplied with CygLink software to display and log thickness measurements from the ROV metal thickness tester to a computer at the surface which can then be saved to a file and printed out. CygLink has two data logging facilities Quick Log for simple recording of thickness measurements and Structured mode with four templates available. The Cygnus Top Side Repeater (TSR) is available as an option and has the facility to display the thickness measurements remotely and overlay them on to a video signal. This allows the measurements to be superimposed on the ROV camera’s monitor screen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The high-performance optoNCDT ILR2250 laser distance sensor is used whenever large measuring ranges and high accuracy are required. The optoNCDT ILR2250 can be installed at distances up to 100 m, and even up to 150 m with a reflector film. This sensor impresses when measuring dark, structured and poorly reflecting surfaces, while providing stable measurement results to millimeter accuracy. The optoNCDT ILR2250 laser distance sensor is used in transportation, logistics and conveyance technologies as well as automation and the metals industry. This is where the sensor enables reliable measurement results even when it is, e.g., installed at a safe distance from heat emitting measuring objects. In addition, difficult-to-access places via mirrors or through glass sheets can be detected.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Thickness measurement on plastic film samples requires automatic transport of the film strips through the measuring device, allowing for the flexibility of the material being measured. The desktop version of the VDM measuring station can be equipped not only with the pure measuring device, but also with PC-aided evaluation and graphic representation of the measurement results.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

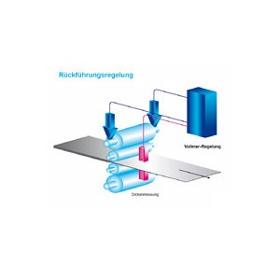

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

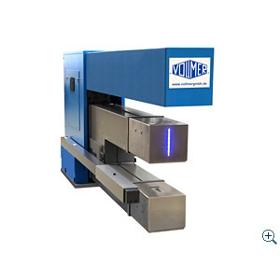

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quote

EUROMET METROLOGY

Turkey

-Static Pressure Test Equipment -LOSS OF PRESSURE TEST EQUIPMENT -WATER METER ENDURANCE (ABRASION) TESTING EQUIPMENT -HEAT METER DURABILITY TEST EQUIPMENT -DOMESTIC WATER METER TEST AND CALIBRATION EQUIPMENT -WOLTMAN WATER METER TESTING EQUIPMENT -HEAT METER TEST AND CALIBRATION EQUIPMENT -MOBİLE TEST UNIT

Request for a quoteResults for

Thickness measurement equipment - Import exportNumber of results

16 ProductsCountries

Company type