- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bending

Results for

Bending - Import export

ATOM KARINCA LASER

Turkey

With our four-roll cylinder bending machines, we can perform cylinder bending for parts that are 3 meters in length, 150mm to 600 mm in diameter. And maximum thickness is 15 mm.

Request for a quote

DOGRAR METAL

Turkey

Our machine selection may bend 240 and 300 IPE and NPI. and pipes from 21 to 76. Moreover, we can process from 15x15 rolling mills to 60x60 rolling mills also, from 20^5 sheet bar to 80x20 sheet bar.

Request for a quote

BASAK LAZER

Turkey

Please contact us for detailed information and offer.

Request for a quote

ILK IHRACAT AS.

Turkey

Our CNC bending service covers the following areas: Metal Part Bending: Bending metal sheets to the desired measurements and shapes. Design Compatibility: We offer customized bending services that match your technical drawings. Shaping and bending materials in industrial projects is a crucial step that defines the final design of a product. Through our CNC bending service, we guarantee the success of your projects by precisely and accurately bending metal sheets. Shape Your Projects Now! Bring your metal parts to the desired form with our CNC bending service. Complete your projects in the best way possible with our precision and accurate bending technology. Get a Quote and experience the difference! Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

cnc press brake

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

tube bending with contract manufacturing

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

welded production

Request for a quote

SEPA ALUMINYUM VE METAL SAN. TIC. AS.

Turkey

Tandem system brakes line twist service we provide different types of metal up to 8 m in length.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Abkant bench is a kind of press machine used in bending or folding metals. Today many computerized Abkant machines are available. It has improved production by making it faster, saving time, and with respect to shapes. Cylindrical, conical, elliptic and oval materials may be produced by Abkant bending process. In selecting Abkant press, length, thickness and type of the material to be folded (stainless steel, aluminum, conventional sheet, ST, etc.) are important. The machines have separate molds and radii specific to them for various folding processes. A calculating metal sheet angle in Abkant folding is a job requiring expertness. Otherwise, folding lengths may not be produced at the required size. We, as Ramazan Aycan Sheet and Steel Processing Center, we provide you with guaranteed services with our expert staff

Request for a quote

FHM METAL ISLEME

Turkey

We are extremely meticulous and self-sacrificing in the pipe bending production we have made. Crack in twist, pot etc. We pay attention to manufacturing faults, and we produce our products in an extremely clean and high quality. Our current production machine supports up to Ø25. We aim to expand our machinery field very soon. We can produce molds on demand, taking into account the number of production, and we can prepare the order you want in the dimensions.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

İt is one of the fundemental machines uesd for works like compression, bending, attachment, bearing removal, stretching etc. Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

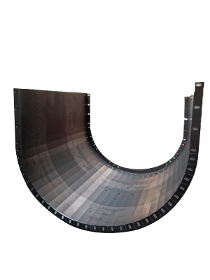

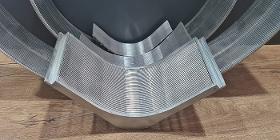

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNIC MACHINES

Turkey

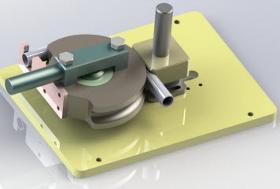

We designed our Semi-Automatic Pipe Bending Machines to have complex pipe bending results easily with servo rotation function during pipe bending process. We can say that our Semi Automatic Tube Bending Machine is economical option of 3 Axes CNC Pipe Bending Machines with lower investment than CNC Tube Bending Machine. General Details - Servo Rotation - NC Control - Direct Gear Transmission - Touch Screen - Hydraulic Clamp-Die/Pressure-Die - Automatic Mandrel Extraction - Adjustable Flip Stops - Quick Changeable Tooling - Automatic / Manual Mode - Warning Messages - Energy Saving Mode Technical Details Tube Bending Diameter Range from 6 mm to 130 mm Ø Pipe Bending Machine Center Line Radius According to Demand Max. Tube Bending Angle 190°

Request for a quote

AHP PLASTIK MAKINA

Turkey

The test chamber is used for performing leak tests on mechanical fittings and pressure pipes under hydrostatic internal pressure while subjected to bending. We can also provide with a pipe tester for building up the test pressure according to ISO 3458. According to ISO 3503 , pneumatic force application , bending templates for different sizes

Request for a quote

BULUT CNC MACHINING

Turkey

Experience unparalleled precision with BULUT CNC MAKINA's bespoke CNC projects, meticulously crafted in Turkey. Committed to excellence, we specialize in tailoring components to match your unique requirements. From intricate machinery parts to bespoke project elements, our team employs cutting-edge CNC milling, turning, and machining techniques for optimal solutions..We redefine excellence in the realm of brass machined parts manufacturing. With a relentless commitment to quality, innovation, and customer satisfaction, we stand as the premier destination for businesses seeking top-tier brass components for their diverse applications.

Request for a quote

ATOM KARINCA LASER

Turkey

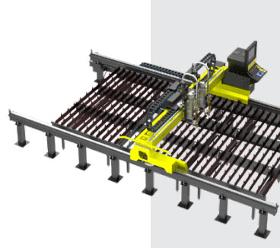

Efficient material utilization in production. Fast cutting for cost-effectiveness in production. Cost reduction through minimal waste rates. Economical production from sheet materials compared to machining. High precision due to the machine’s stable construction and modern control and measurement technology (accuracy in all dimensions 0.01 mm). Drilling hole diameter is up to 0.4 mm of sheet thickness Marking can be done on the work pieces. No burrs or heat deformations on cutting surfaces. More flexible design possibilities.

Request for a quote

ATOM KARINCA LASER

Turkey

ATOM KARINCA can do even the most complex sheet bending operations with the high-tech CNC bending machines and experienced team. We can perform bends with a precision of 0.20 degrees on 3 meters long pieces. Thanks to the station bending capability of our AMADA bending machines, we can produce high-quality parts with repeatable precision.

Request for a quote

ATOM KARINCA LASER

Turkey

It can quickly weld stainless steel and mild steel materials even for high-volume orders. In addition to robotic welding, we professionally perform TIG welding for stainless steel and aluminum by our certified welding team. We provide different welding procedures, i.e. MIG, TIG and spot welding.

Request for a quote

ATOM KARINCA LASER

Turkey

CUTTING CAPACITY 300 mm Mild Steel 50 mm Stainless Steel 50 mm Aluminum plasma cutting We provide high-quality results in cutting various thicknesses of mild steel, stainless steel, and aluminum materials. We also provide beveling up to 45 degrees and marking.

Request for a quoteResults for

Bending - Import exportNumber of results

84 ProductsCountries

Category

- Bending - steels and metals (40)

- Bending machine tools (10)

- Laser - cutting and welding machines (5)

- Steels and metals - machining (5)

- Industrial sheet metal work (4)

- Sheet Metal & Tubes (3)

- Testing equipment (3)

- Forming - steels and metals (2)

- Cutting - steels and metals (2)

- Steels and metals - forming and cutting (2)

- Steels and metals - welding and brazing (2)

- Stainless steels (1)

- Metal industrial presses (1)

- Pipes and tubes, copper (1)

- Welding work - steels and metal (1)

- Cutting - machine tools (1)

- Machine tools - metal machining (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Agricultural systems and equipment (1)

- Components and parts for large household appliances (1)