- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feed

Results for

Feed - Import export

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

SACFORM/AGMLINE

Turkey

Zigzag Servo Feeding System, Which Moves in Two Axes (X And Y), Is Specifically Preferred for Minimum Waste at Perimeter/Flake Cutting Processes. Its Body Structure Design Enables to Easily Adapt to All Kinds of Press Machines.

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACS Series compact system press feeding machines consist of 600 and 1600 coil width, 2 and 10 mm of sheet metal thickness, between 6.000 and 15.000 kilograms of coil weight capacity feeder, straightener and decoiler. 11-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

ROBINSON CO.

Turkey

Molasses Mixer designed for homogeneous mixing of liquid sweetener to product additives in feed mill plants. U type body in Carbon Steel ST37 metarial up to requirement. Liquid with 1-11 % is mixed homogeneously. Maximum mixing is provided by heating molasses 40 - 42 degress. Applications Fields Food Business Industries Flour Mills Semolina Mills Seed Cleaning Facilities Malt Factories Feed Mills Corn Mills Grain Storage Silos

Request for a quote

ROBINSON CO.

Turkey

The mixer is designed to homogenize the mixing of different raw materials milled to the mill with poor free flow during the process. Both types of mixing are possible with or without the addition of liquid. it provides a mixture of raw materials crushed with a precision of 1/100000. The loading time is reduced by pneumatic traps in a large area; and the unloading time is reduced by double unloading hatches that can be opened from end to end.The position/time increases with the time gained during the finishing process.There are 100% safe unloading housings that do not load Rotating equipment should never be opened unless the cycle is completed. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

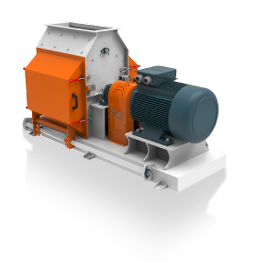

This hammer mill grinds easily raw materials which are dry and lle dampens fine. For this reason it is used in food industry.The body is of steel and weld construction. The hammers are on the rotor which turn a mill. The rotormill turns in the strong ball thrust. The hammers are made of hardened steel.It is designed turn free.The sieve is on the hammer mill and it is changed easily without stopping the rotor. Motor is connected directly to the coupling. The body of hammer mill is mounted on the same chassis. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Counterflow cooler is utilized for cooling the feed that comes out from pellet mill in pellet form which is hot, to ambient temperature. It works according to steady air form principle. Air in the external environment contacts the feed in the cooler; while the temperature of the feed drops, warm air is removed from the environment through air aspiration system.Discharge system which is on the cooler, removes cooled feed. Drainage system can be chosen with grid or hydraulic valve depending on the preferred product. Drainage system is adjustable and works according to the capacity. Applications Fields ◾ Feed Plants

Request for a quote

ROBINSON CO.

Turkey

Vibro Sieve; sticky filter flour and fine products from bran brushes, etc. It is used in the process of sieving the substances. Vibro Bran Brush; It separates the flour in the bran by 95% -98%. Application Fields Flour Mills Semolina Mills Corn Mills Feed Mills At food Processing Industry

Request for a quote

ROBINSON CO.

Turkey

It is designed to feed the control sifter properly. The flour distributor is mounted on control sifters. It enables to feed the control sifters regularly and in equal quantities. Flour enters the distributor through the middle center and is distributed evenly from all outlets of the distributor with the help of a rotating chamber driven by a reducer motor. Various capacities and models are available according to the requirement of the sieve. Application Fields ◾ At food processing industry ◾ Flour and semolina mills ◾ Macaroni factories ◾ Feed mills ◾ At other similar industrial plants

Request for a quote

ROBINSON CO.

Turkey

It is used to transport the products pneumatically to different points over a single line. It allows to change direction during transportation. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

The wing formation inside the machine feeds the product at a stable rate to the transport line. The accurate tolerance between the body and the wings prevents the pressurized air to reach the product inlet. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Pellet mill’s working principle is, mash feed is forced outward through holes in a ring die by the action of two or three rollers, which is then cut to a predetermined size. Before mechanical process, steam can be injected into the conditioner at temperature 85 degrees celsius. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

The pellet crusher is a crusher specially designed to break 03-5mm granules into small pieces. With this design, the quality of pellet feed and pellet feed is improved. It is mainly used for poultry and fattening pellets and aquaculture pellets. The pellet crusher has two rollers, the working distance of which can be adjusted (manually or by motor). Thanks to the specially designed abilene rollers, all kinds of grains are processed with high capacity and quality. These rollers can always be used correctly to ensure high efficiency. The roller mechanism is fed regularly by the power supply unit. The pellet is evenly distributed over the entire surface of the roller. Thanks to a regular feeding with this mechanism, a homogeneous structured feeding with a low power and a lower dust content is obtained without overloading the machine. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

Dosing screw conveyors of different sizes are used to provide weighing accuracy. Micronutrients are weighed and dosed into the scale. The weighing accuracy is not affected thanks to the flexibility of the connection between the scale and lower tank. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EAE ELECTRIC

Turkey

Flexibility in Rack Cabinet Power Feeding (160A-1000A)Our new DATA RACK BUSBAR addresses configurability concerns for reliable and flexible Moves- Adds-Changes(the routine work performed on computer equipment) in your data centre white space power infrastructures.

Request for a quote

DAMS MACHINE

Turkey

Roll, Sandwich Hamburger and similar sized products and Francala Bread are individually wrapped. Our machine has a servo motor system. Thanks to the touch screen and PLC on the machine, product package length, photocell adjustment and machine speed can be adjusted as desired. There is a sensor control system that prevents jamming of the product. If the product location is not correct, it stops the machine. All surfaces and covers that are in contact with the product in the machine are made of 304 quality chrome-nickel metal. Rotating jaw system. It packs 115 products per minute (roll, sandwich hamburger and similar products), and 83 products per minute in Francala Bread. It easy to use. Optionally, it is produced so that a coding device can be mounted on the machine. Cellophane bobbin is easy to disassemble and install, the place where it is mounted is an air system and PLC controlled shaft.

Request for a quote

TECHNIC MACHINES

Turkey

Our compact coil feeder and straightener machine is for custom solutions on press feeding equipment’s results with minimum necessary space solution. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our compact coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system and as single machine body for coil decoiler, straightener and feeder. Also straightener feeder has single body design on our compact coil feeder machine system. We provide compact coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used for homogeneous mixing of powdered and granular products

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used in rough cleaning of the raw materials for removing foreign materials from wheat and all other cereals before processing

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is designed to get small size particles from granular products at flour and feed mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed regularly the granular or powdery product into a conveying line or a machine at a suitable rate especially at flour mills

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to feed the product regularly into pneumatic conveying pipes at the pneumatic conveying systems

Request for a quote

TECHNIC MACHINES

Turkey

Our coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system but separated or as single machine body for coil decoiler, straightener and feeder. We provide coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quoteResults for

Feed - Import exportNumber of results

90 ProductsCountries

Company type

Category

- Feeds for animal farming (19)

- Flour milling - machinery and equipment (13)

- Cattle, dairy (9)

- Bird cages and aviaries (7)

- Troughs and feeders (5)

- Animals & Livestock (4)

- Axles, vehicle (4)

- Livestock and poultry - feed (3)

- Animal feeding equipment (3)

- Feed for fish farming (3)

- Metal straightening machines (2)

- Cutting - machine tools (2)

- Mining and quarrying - machinery and equipment (2)

- Oils, cooking - machinery and equipment (2)

- Poultry farming - machinery and equipment (1)

- Food for livestock and poultry (1)

- Farm machines (1)

- Baby-care products (1)

- Feed distribution systems (1)

- Foods, health (1)