- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical operations

Results for

Mechanical operations - Import export

ROBINSON CO.

Turkey

It is designed to give water into the wheat during the tempering of the wheat. The semi-mechanically operating system is mounted on forced annealing machines or internal leak screw screw. The water to be supplied to the system is first filtered and cleaned, and the sensor detecting the flow of wheat delivers the amount of water whose flow rate is adjusted beforehand to the system by opening the solenoid valve, the sensor closes the solenoid valve when the flowing wheat is cut. There are various types of flowmeters, and special types are manufactured according to the application place and flow. Application Fields ◾ At food processing industry ◾ Flour and semolina mills ◾ Macaroni factories ◾ Feed mills ◾ At other similar industrial plants

Request for a quote

EAE ELECTRIC

Turkey

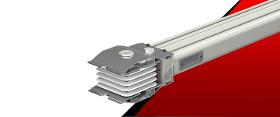

IP68 Aluminium Housing Cast Resin Busbar (600A...6300A)Aluminium housing covers the “DUROCOMP” composite material that is manufactured from specially selected pure silicium minerals and epoxy resin and has superior temperature and mechanical operation features and insulates the E-Line CCR Busbar from external elements.

Request for a quote

ANKARA BRONZ

Turkey

Much lower coefficient of friction than Kestamid High resistance to wear High resistance to impact High crystal structure Higher stability Much lower water absorption than Kestamid Excellent performance in abrasive sludge and sea water Ideal for environments where it is difficult or impossible to lubricate Very low heat build-up on the surfaces Corrosion resistant Excellent resistance to many chemicals Easy mechanic malleability Quiet and impactless operability Bone color in places where is in contact with good and medicine Product Description Kestoil is an ideal engineering plastics for self-lubricating, robust, abrasion-resistant, low coefficient of friction, non-lubricated bearings and cradles that have many features that do not coexist in other materials. Kestoil is a Kestamid which includes various lubricants, impacts and abrasion resistant additives to its structure during its production. The lubricant additives

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

FG CALCIUM SULFONATE is a high-performance grease specifically designed for applications in the food processing industry, addressing the demands of high-load and humid environments. Formulated with a calcium sulfonate thickener, this grease exhibits a strong affinity for metal, maintains exceptional stability during mechanical operations, and offers excellent lubrication and anti-oxidation properties. Its semi-synthetic base oil not only extends its working temperature range beyond that of typical greases but also ensures performance remains intact between -30°C and 170°C. Carefully balanced additives contribute to outstanding anti-corrosive, anti-oxidant, anti-wear, and extreme pressure-resistant properties, all essential for reliable performance in the most challenging applications.

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment.As Per International Standard

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment. Using a steel sling to load

Request for a quote

KEDY

Turkey

The K2950 Automatic Beam Tong from KEDY is the ultimate tool for lifting and moving heavy beams and other objects with ease and precision. Its innovative locking mechanism eliminates the need for operator intervention, ensuring a safe and efficient lifting operation. The tongs lift loads evenly, ensuring the safety of your materials. The polyamide pads protect your materials from damage while lifting. The handles provide a convenient way for operators to guide the tongs, making it easy to maneuver and position the load. Additionally, the K2950 Automatic Beam Tong is built to last, constructed with durable materials and designed to withstand the rigors of heavy-duty use. Whether you're working in construction, industrial, or manufacturing settings, this tong is the perfect solution for all your heavy-lifting needs. With its advanced features and ease of use, the K2950 Automatic Beam Tong from KEDY is the best choice for professionals who demand the highest quality and performance.

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

In comparison to conventional water treatment processes, the advantage of "ultrafiltration" as a filter technology is its superior ability to remove germs and microorganisms from water. At around 20 nm, the pores of the membrane are small enough to prevent even viruses from passing through them. "Ultrafiltration" systems are designed for fully automatic operation. A control mechanism is used to control the various operating modes of the ultrafiltration process: filtration, cleaning and backwashing. enki’s industrial ultrafiltration units are available from 25 to 500 m3/h and more . Our ultrafiltration systems are available in either Outside-In or Inside-Out configurations. Outside-In configuration UF Systems; DOW H-PVDF Hollow Fiber UF Membranes Inside-Out configuration UF Systems; Inge PESM Hollow Fiber UF Membranes

YILMAZ MACHINE

Turkey

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor Remote connection via internet and providing technical support

Request for a quote

YILMAZ MACHINE

Turkey

VK 420 is designed for the precise V cutting and 90° end notching operations with minimal off cut size on aluminum and PVC profiles. Machine is constructed to minimize the off cut size Hydro-pneumatic V sawing head infinitely adjustable according to the profile Manual adjustable of back fence working in T slot mechanism Double hand safety operation External adjustment of hydro-pneumatic saw blade feeding 90 degree of notching operation (optional) STANDARD ACCESSORIES • 2 x T.C.T saw blades, Ø 420 mm • 2 x Horizontal pneumatic clamps • Service spanner • Air gun • Spray saw blade lubrication system

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

NOKSI METAL

Turkey

Bins Material: 304/430 Stainless Steel Quality Finish: Polished Capacity: 3/5/8/12/16/20/30/40 LT Foot oerated,hands free operation Smooth,positive action Hygienic plastic inner bin No slip,non marking base Durable heavy duty opering mechanism Convenient carry handle

Request for a quote

MIR ARENA

Turkey

Manufactured from PE and PP According to EN ISO 4892-2 standard anti UV additive Corrosion resistant in compliance with EN ISO 9227 Standard In compliance with EN ISO 11925-2 and 13501-/E class fire-resistance In compliance with EN ISO 13200-4 Standard highly resistant to hooliganism Tip-up mechanism of the product operating with the center of gravity system The metal parts of the seats are designed and produced by laser cutting without seamless of monolithic 6 mm sheet and bending in press molds Seats are firmly attached to the barriers with the rail system mounted on the steps Fewer dowels are used on the steps with this system. This system allows the seats to be shifted from right to left, and allows them to be easily replaced with new seats in future times Plastic weight of the seat is 3,250 gr and total weight of the seat is 9,540 gr The armrest of the seat is made of PP Advertisement area is in the back surface of the seat

Request for a quote

MIR ARENA

Turkey

Manufactured from PE and PP According to EN ISO 4892-2 standard anti UV additive Corrosion resistant in compliance with EN ISO 9227 Standard In compliance with EN ISO 11925-2 and 13501-/E class fire-resistance In compliance with EN ISO 13200-4 Standard highly resistant to hooliganism Tip-up mechanism of the product operating with the center of gravity system The metal parts of the seats are designed and produced by laser cutting without seamless of monolithic 6 millimeter sheet and bending in press molds Plastic weight of the seat is 3,250 gr and total weight of the seat is 9,540 gr The back and the seating part of the product is manufactured from leather upholstered polyurethane foam

Request for a quote

MIR ARENA

Turkey

Seating and back units of the product is metal frame embedded in polyurethane foam where density is 50± %10 In compliance with EN FMV SS 302 fire-resistance standard Corrosion resistant in compliance with EN ISO 9227 Standard In compliance with EN ISO 12727 Standard highly resistant to hooliganism Artificial leathers used in upholstery are produced with additives that provide high resistance to salt, UV rays, fire and chlorine The artificial leathers used in the upholstery are covered with 4 millimeter lamination which has non-flammable properties Antipanic folding tablet placed inside the armrest Tip-up mechanism of the product operating with the center of gravity system The metal parts of the seats are designed and produced by laser cutting without seamless of monolithic 6 millimeter sheet and bending in press molds Armrests of the seats are made of MDF over metal frame and covered with laminated leather Provides space in the tribunes with the ergonomic and slim structure

Request for a quote

ROYAL GLASS TECHNICAL GLAZING SYSTEMS

Turkey

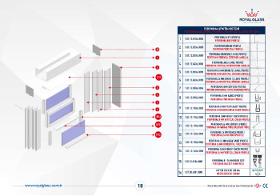

All edges; are framed by special designed aluminium. 8mm tempered glasses or laminated glasses. Number of panels; 1 + 1, 1 +2;1 +3 ,tor 26 mm thickness 1+ 1, 1+2 ; panels tempered or laminated, secured engine drive , and thanks to the gear chain , it has been transported jambs without imposing any burden to the glazing units, within wide angled coupling corded staple characteristic , it provides insulation and wind resistance and operating vertical. Mechanism is stabilized by double- row gear and double- row chain ; the safe bearing capacity tor load ; the maximum panel weight is; (170 kg)x 20 times (Min) BECKER Motors Ltd. (Made in Germany) 153,9 mm X 140 mm (Width X Lenght), inbuilt multipurpose insulated and lock concealed screw. Switch controlled or remote control . Eager tor bonding and fast curing, not including extra solvent; lmplemented on neat surface. Sound lsolation: along horizontal scale, to the interior and exterior side of upper box; 20 mm thickness, 150 DNS

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TEKNOMASYON

Turkey

-Pneumatic cylinders -Solenoid, Pilot, manual and mechanical operated directional control valves -Flow control valves -ISO and Micro valves -Pneumatic hoses -Air treatment units -Piston operated valves and pulse solenoid valves -One touch plastic - metal - stainless steel fittings -Pneumatic accessories

Request for a quote

DENMAK MAKINA LTD STI

Turkey

BPM-700 concrete spraying machines and systems designed by DENMAK MAKINA are a must-have in your equipment pool due to their low price and low processing cost and ease of use. Due to its rotor structure, it is possible to use any commonly shotcrete material. By its advanced rotor geometry, hardened steel plates and special composite rubber plates it has less air and electricity consumption on operation than its competitors. Its specific oiling system lengthens the life of rubber discs by reducing mechanical wears and optimizes the operating costs. Double sealed water and dust resistant electrical panel provides safety to the operator, which is very crucial at worksite environments. Due to the ease of spare part replacement,it doesn’t require any qualified personnel or doesn’t need any calibration or adjustment to be done afterwards. It can be used in low ceilinged and narrow spaces because of compact design.

Request for a quote

DENMAK MAKINA LTD STI

Turkey

BPM-750 concrete spraying machines and systems designed by DENMAK MAKINA are a must-have in your equipment pool due to their low price and low processing cost and ease of use. Due to its rotor structure, it is possible to use any commonly shotcrete material. By its advanced rotor geometry, hardened steel plates and special composite rubber plates it has less air and electricity consumption on operation than its competitors. Its specific oiling system lengthens the life of rubber discs by reducing mechanical wears and optimizes the operating costs. Double sealed water and dust resistant electrical panel provides safety to the operator, which is very crucial at worksite environments. Due to the ease of spare part replacement,it doesn’t require any qualified personnel or doesn’t need any calibration or adjustment to be done afterwards. It can be used in low ceilinged and narrow spaces because of its compact design.

Request for a quoteResults for

Mechanical operations - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Auditorium seats (3)

- Buckets and grabs, crane (2)

- Cylinders, pneumatic (1)

- Dustbins, waste bins (1)

- Water treatment, industrial - systems and equipment (1)

- Aluminium and aluminium alloys (1)

- Concrete constructions (1)

- Construction machinery (1)

- Cranes and gantries (1)

- Cutting - machine tools (1)

- Doors and gates, automatic and access control (1)

- Electrical systems and equipment (1)

- Flour milling - machinery and equipment (1)

- Lifting equipment (1)

- Lubricants for cars (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)