- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining centres

Results for

Machining centres - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Box Jaws are suitable for heavy duty workholding on large sized lathes, large face plates fitted on Vertical Machining Centres, boring lathes and jig installations and provide a secure method of holding the workpiece.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

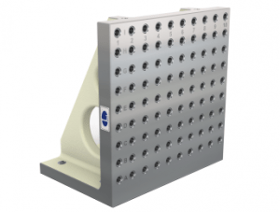

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

A Chick Workholding Foundation Plate is tailored to fit the machine’s specifications. A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups. Length and width tailored to the machine’s work envelope. Precision ground cast iron to 35mm thick. 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs. An alpha-numeric labelling system. Minimises set up time from workholding system to system. Machine interface mounting holes, customised for each machining centre.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

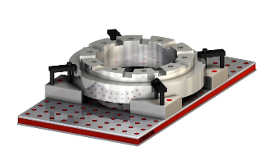

High clamping torque, high accuracy and high rigidity, Kitagawa NC Rotary Tables feature proven technology. The use of rotary tables allows the benefits of one-hit machining to be exploited to the full. Through this process, most - if not all - metal cutting requirements are undertaken by a single machining centre, irrespective of component complexity. The advantages of such a technique are clear. They include: only one machine set-up; one fixturing set-up; cost and time savings associated with reduced parts handling; and the elimination of tolerance errors accumulated as workpieces are moved from machine to machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce your set-up times by more than 90%. Self-clamping mechanism, constant air not required Made from aluminium or stainless steel Thermal compensation included DESCRIPTION Created for use on CNC machining centres, the V-Tech Zero Point system’s unique design guarantees the secure and precise clamping of workpieces, even under tough conditions. The pneumatic, quick change and ZERO POINT clamp features compact dimensions, extraordinarily high clamping force and is made from top quality materials. These stainless steel pull studs can be fitted to fixtures, workholding and even directly to workpieces for easy mounting to the V-Tech zero point baseplates. Pull studs are available as a fixed position type for precise location as well as types with either one or two axes of thermal compensation. Plastic pull studs are available for use as blanking plugs for receivers when not in use.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Reduce your set-up times by more than 90%. Self-clamping mechanism, constant air not required Made from heat treated refined steel Positioning slots allow for indexing by 90° Created for use on CNC machining centres, the V-Tech Zero Point system’s unique design guarantees the secure and precise clamping of workpieces, even under tough conditions. The pneumatic, quick change and ZERO POINT clamp features compact dimensions, extraordinarily high clamping force and is made from top quality materials. V-Tech clamping and location elements can be purchased individually to easily adapt workholding and fixtures for lightning fast changeovers. V-Tech receivers are also available as a . Each V-Tech receiver provides 24KN of clamping force and has positioning slots to allow for indexing by 90 degrees. The self-clamping mechanism means the force is still applied after the air has been disconnected.

Request for a quoteResults for

Machining centres - Import exportNumber of results

8 ProductsCountries

Company type