- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel%20&%20metals

Results for

Steel%20&%20metals - Import export

STALEVAR COMPANY LLC

United Kingdom

Basement inputs and transitions are permanent joints of polyethylene and steel pipes "polyethylene steel", intended for installation in the places where the underground pipeline exits from the ground. The permanent connection is made in a steel case to protect the basement entry from mechanical damage and prevent pipe cooling. Basement inputs are subdivided into L shaped bushings made of insulated steel pipe; bushings made by free bending of a polyethylene pipe with a polyethylene steel transition device; bushings with straight sections of insulated steel and polyethylene pipes; L shaped bushings, combined with the transition "polyethylene steel", insulated with fiberglass. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

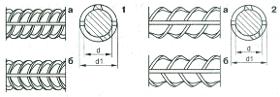

A armature is a product or a blank (an intermediate link in the production of any part, equipment) made of strong steel grades, the use of which is widespread in many industries, the automotive industry, and agriculture. A feature of such a blank is its similarity in shape and size with the future product. Strength, flexibility, wear resistance made them indispensable components in the production of various parts. Raw materials for the production of such products are carefully selected taking into account their future field of operation. They reveal what loads the part will be subjected to in the future, in what environment it will be used. After processing the information received, the most suitable steel grades for specific operating conditions are selected. Common steel grades for the manufacture of forgings are 20, 20X, 35, 35 40, 45, 40X, 08X18H10T, 09G2S, 12X13, 12XN3A. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

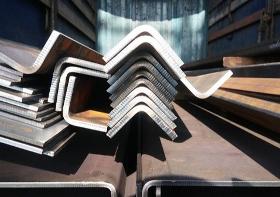

Products from a bent profile are made from hot rolled (hc) and cold rolled (hc) sheets (rolls) with a thickness of 1.5 to 5 mm on special industrial bending machines and guillotines with consistent dimensional data, in accordance with GOST (TU). The range of metal products obtained from a flat billet bent channel GOST 8278; bent corner GOST 19771. The bent channel is designed to significantly lighten and reduce the cost of the final cost of metal structures and other demanded products. Despite the fact that it is less durable in comparison with the hot rolled analogue , its use is in demand in mechanical engineering, furniture factories and manufacturing companies. The length of the billet of the channel is 6 meters, the width of the flange is from 30 to 200 mm, it is possible to manufacture a bent channel by special order . You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Steel square GOST 2591 88 is produced hot rolled and cold rolled high (B) and normal (C) strength. The products are in demand in the engineering and manufacturing industries, and are also widely used in construction and in everyday life. The following types of metal products are made from it tools, fences, gratings and mechanical engineering parts. Dimensional grid of steel square billets 10 200 mm, steel grades St.3 St.45, St.40X, etc. It is used in the manufacture of products obtained mechanically on milling and turning machines. The calibrated steel square is produced by the cold rolled method with increased strength and accuracy of edges and sides, which means that it does not require additional machining of the sides, which subsequently reduces the time and resources for the production of the final product. The length of the workpiece to be produced is usually from 2 to 6.3 m. The maximum deviation of the flatness of a metal product along its long part is no more than 1%.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

The hot rolled steel circle is produced at Ukrainian factories, it is an excellent material for the manufacture of a wide range of products produced by the mechanical method on lathes and cutting machines, metal structures , supports, and other products. The steel circle is in demand in mechanical engineering, manufacturing, construction. It is used for making bushings, cylinders, locks, guides, rods, grids, dumbbells, swings, horizontal bars, lattices, washers, linings, pins and other cylindrical products, seamless pipe . Hot rolled steel circle GOST 2590 88, its standard dimensions length from 4 to 6.3 m, thickness from 10 mm to 330 mm. One of the varieties of round products is a calibrated circle produced by the method of cold drawing, grinding, polishing the surface of the product, and the compliance of surface dimensions to microns, which does not require further mechanical processing. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STALEVAR COMPANY LLC

United Kingdom

Rail transport is one of the few opportunities for moving large volumes of cargo by land. Thanks to these exceptional capabilities, his services are in maximum demand in all industries, both now and in the future. A rail is an element of a railway track, which directly takes the entire load of the rolling stock. Constructed from carbon steel and fixed to timber or concrete sleepers We offer domestic made railway rails and other rail products widely used in Ukraine of various types and modifications for wholesale and retail purchases, as well as components for them. The range of rails we offer makes it possible to repair a wide range of types of rail fasteners, from access roads of industrial enterprises leading to main roads, to industrial rail sections located inside buildings, turnouts, underground mine tracks, as well as their construction. The length of a railroad train is from 12.5 to 100 meters. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Hot rolled steel strip is produced from a part of a metal sheet (coil) on a guillotine installation by shearing or hot rolling necessary for the manufacture and production of various flat fastening structures, tools, components and assemblies, while substantially alleviating our labor costs, energy costs and time for the preparatory process, and cutting the sheet. Overall dimensions of a flat workpiece length up to 6 meters, thickness 3 20 mm LLC "Company STALEVAR" can produce hot rolled strip , according to the specified conditions and overall dimensions of the buyer. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

Steel reinforcement is used and necessary for the construction of buildings, concrete structures, formwork, structures, which makes it possible to manufacture a reinforced concrete structure that is stronger and more durable, it is produced at factories in Ukraine with a set length of 12 meters. Depending on the strength requirements for the future building structure, its diameter is selected. For example, for the foundation of a fence, the diameter of the reinforcement can be 8 mm, but for building a house, a thickness of 10 12 mm is required, for bridge cranes 36 40 mm. The surface of the construction reinforcement is made in the form of notches specially for better fixation in concrete. The growth rates of construction in our country and in the world as a whole are constantly increasing. Every day, new materials and advanced technologies appear that significantly improve this process. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

PROSAW LIMITED

United Kingdom

ASM model is made of cast iron construction. ASM machines are combining the user friendly features, quality and best prices as an economical model. ASM - 3 Rolls Asymetical Plate Roll Machine Standard Details Body is made of cast iron construction Central rollers powered with electric motor, gearbox and gear drive Cone bending device Self brake main motor Upper roll is opanable by side Lower roll and back roll are with hand wheels up & down adjustable. Separate eletric control panel with foot pedal Suitable for CE, ISO 9001-2008, TSEK and TURQUM certificates ASM - 3 Rolls Asymetical Plate Roll Machine Optional Features Induction hardened rolls. Back roll with motor. Digital display.

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

To complement our additional services, we offer a complete in-house polishing service. Our purpose built multi-head polishing machine allows us to provide the complete range of finishes, from a dull 180 grit to a super mirror 600 grit. This lets you choose the exact finish you desire every time without the worry of stock availability. The polishing service can accommodate any length of tube or round bar up to 6 metres in length.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We provide our customers with the opportunity to get their materials processed before they even leave the warehouse – providing a leaner and more cost-effective manufacturing process. With large quantities of material stored on site, you’ll benefit from shorter lead times and better material availability compared to third party subcontractors. Thanks to recent investments, our manipulation service operates across two sites, equipped with several single and multi-stack benders and end-forming machines. Through these sites, we provide CNC and Press tube bending, end-forming and cruxiforming - providing the Group the capability to process and deliver orders faster than ever before. Our manipulation services are currently being employed within the automotive, domestic appliance and filtration industries.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Our specialist-built cutting shop is fully equipped to suit your needs. In addition to our laser cutting facilities, we have a bank of fully automatic and semi-automatic cutting machines ready to process materials up to 3,000mm in length. With the capability to hold tight tolerances (+/- 0.20mm) on diameters ranging from 6mm - 153mm, our cutting services are the cost-effective option for high volume repetitive cut orders. Whether you choose the built-in deburring and washing options or the stand alone alternatives available alongside the cutting service, your components will be completed to a high standard of finish.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Our state-of-the-art fibre laser provides you an unprecedented level of freedom in design. Capable of processing tube and box material in varying aluminium, stainless steel and titanium grades and thicknesses. Our laser service provides you with a wealth of new options to consider. As an All-In-One Solution, our laser can do more than just cut material. The laser can implement multiple functions in a single operation, including: cutting, drilling, notching and etching. What once would have taken hours and multiple operations and personnel, now only takes seconds with the help of our friendly Laser Operators, Adrian and Martin. Opposed to traditional cutting methods, laser machines do not require contact upon cutting, -minimising contamination and unwanted marking to the material. When paired with the internal suction probe (more commonly known as “the spoon”), we can produce a final product to a higher standard of finish both in terms of cleanliness and aesthetically.

Request for a quoteResults for

Steel%20&%20metals - Import exportNumber of results

16 ProductsCompany type

Category