- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water jet cutters

Results for

Water jet cutters - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ceramic Plunger Waterjet Cutter Innovacera develops many kinds of Zirconia ceramic parts for all kinds of pumps & valves . Such as waterjet zirconia ceramic plunger for severe service and high pressure systems . Waterjet intensifier ceramic plunger for water jet is used on 60k ultra high pressure intensifier waterjet pump 50HP, 60HP,100HP, 40KPSI, 60KPSI. The max pressure it undertake can be 60 kpsi , voltage 220v/380v. Innovacera Waterjet Ziconia Ceramic Plunger Features: > Mirror polished > High pressure resistant > Wear and corrosion resistant > Long Service Life & improve seal life > Good toughness and fracture strength > 10 years expertise in manufacturing zirconia pump components for OEMs Waterjet Ziconia Ceramic Plunger Size Specifications: - 22.22*207mm - 22.22*318mm - 22.22*236mm

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Cora®Jet is a water jet bonded polyester fleece. It is characterized by a very uniform fibre structure. The large material thickness also supports the deposition of the particles in the depth of the filter medium.

Request for a quote

BLASQEM, LDA.

Portugal

Range of products manufactured mainly in the USA. Decades of experience in the development and manufacture of components and waterjet cutting systems, allow us to present our customers with high performance solutions at reduced costs.

Request for a quote

MARXAM PROJECT

Poland

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of even 1mm). The use of aqua cutting with high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or time-consuming and expensive using other methods. Using this method, we can process, materials such as: - Ceramic materials - Glass - Plastics - Titanium and its alloys - Materials sensitive to high processing temperatures - Structural, alloy and tool steels (of any degree of hardening) - Cast iron, steel - Copper, brasses, bronzes - Molybdenum and its alloys - Wood and wood-based materials Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

Request for a quote

FINEPART SWEDEN AB

Sweden

Finecut 4-Axis Waterjet Machine, a Micro Abrasive Waterjet, Beyond Cutting Edge. Precision with rotating work piece 4 axis working synchronously Cutting width down to 0.2 mm Live fixturing for cutting part from different sides Rotates workpiece synchronously with cutting High inclination angles Utilizes 5-axis control with tool center point function Cutting With 4 Axis Rotary Table The A-axis can be fitted with a work table plate on which any work piece can be placed. With this mechanism the part can be reoriented to provide access for cutting from different sides of the part. This motion system setup allows the waterjet nozzle to cut along a contour, following the part’s 3D curvature, moving all four axis in synchronous motion. Easy CAD/CAM Programming The machine has a 5-axis waterjet controller with capability for tool center point programming. All these operations are easily programmed using the CAD/CAM software provided with all Finecut waterjet machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FINEPART SWEDEN AB

Sweden

High Speed Complex Precision 5 Axis Waterjet Cutting Technology, Ideal For Prototyping Ideal for prototyping or one-off parts and cutting highly complex shapes, with cutting width down to 0.2 mm. 5-axis cutting with tool center point control and corner optimization by waterjet motion strategy. Cutting width down to 0.2 mm 3 dimensional cutting 5-axis cutting with tool center point control High inclination angles and complex shapes Perfect for prototyping FINECUT MICRO ABRASIVE WATERJET TECHNOLOGY Advantages and Capabilities Increase Your Productivity, Cutting Speed, Precision, While Doing Complex Cutting. Ideal for prototyping Ideal for applications that require complex cutting 3D abrasive cutting capabilities Cutting 2X as fast, compared to 3 axis cutting Ultimate taper control and taper elimination Able to cut materials of almost any kind, both soft and hard materials

Request for a quote

FINEPART SWEDEN AB

Sweden

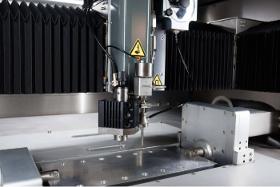

Finecut 3-Axis Waterjet Machine, a Premium Micro Abrasive Waterjet, Beyond Cutting Edge. Cutting width down to 0.2 mm Designed for ultimate precision cutting Highly dynamic and fully encapsulated motion system Flexible fixtures for different applications Intuitive HMI Easy set-up. Easy to operate. Easy to service. Ultra-High Precision Water Jet Cutting Machine – with Finecut™ WMC 500 II Waterjet Machining Center … BEYOND CUTTING EDGE Micro Abrasive Waterjet technology is the proprietary cutting system of Finepart. It was developed to accompany the Finecut Waterjet Machining Center and together they bring the waterjet technology to a whole new level of precision cutting. The micro abrasive waterjet process is a particle erosion based, non-thermal cutting process. This process can cut virtually all materials and produce an excellent surface finish that does not change the material properties.

Request for a quoteResults for

Water jet cutters - Import exportNumber of results

8 ProductsCountries

Company type