- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- t profiles

Results for

T profiles - Import export

RHIMEX.COM

Netherlands

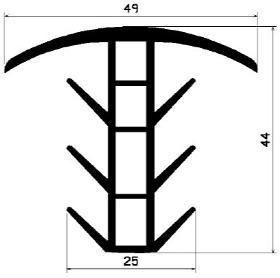

Tprofiles are specially made to seal gaps or crevices, of doors, hatches, windows or with sheet material. High elasticity protects against tearing EPDM and TPE UV and ozone resistant Widely used in ship and bodywork construction

Request for a quote

IGUS® GMBH

Germany

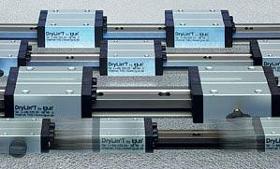

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

NORELEM FRANCE

France

Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt flexibility. Permits smallest pulley diameters. The toothed belts are intended for drives where precision is a requirement, safety is important and the effects of chemicals are a concern. maintenancefree highpower transmission minimal belt extension accurate positioning and angles very good chemical resistance, especially to oils, greases and fuels extremely high abrasion resistance transmits power up to 30 kW reliable speed up to 10,000 rpm

Request for a quote

NORELEM FRANCE

France

Aluminium. Rim flanges, steel. Version Aluminium bright. Steel electro zincplated. Note Standard T profile acc. to DIN 7721 T2 with metric pitch (trapezoidal toothing). At least one belt pulley must have a rim flange. The toothed belt pulleys have a centre bore or a pilot hole (this can vary due to manufacturing methods). For this reason, the dimension D2 max. given in the table is the maximum diameter of the bore with which the toothed belt pulleys are supplied. This pilot/centre bore can be amended by the customer to produce a reamed bore, reamed bore with keyway or a tapped hole. Alternatively, customers can also use bushes to reduce the bore diameter.

Request for a quote

ALUSELL

Turkey

Aluminium Tubes, Aluminium Boxes, L Profiles, H Profiles, T Profiles

Do you sell or make similar products?

Sign up to europages and have your products listed

FIP ARTICOLI TECNICI S.R.L.

Italy

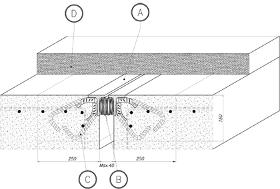

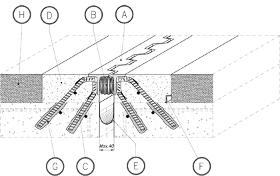

Joint 90/65 AS (levelled wings) was specifically designed for highway use within structures creating longitudinal movements of ± 15 (mm), vertical movements up to 10mm. It consists of an extruded rubber bellows, vulcanized to two 65x80x9 mm T-profiles and anchored to the slab by clamps of suitable diameter, placed at centre distance of 240 mm. The extruded rubber, together with the steel profiles it is vulcanized to, makes up a water-tight system and seamlessly covers the entire width of the road bed. Water-tight capacity around the areas close to the joint is ensured by appropriate water-proof materials. POS. DESCRIPTION MATERIAL A 80x80x9 "T" profile S235JR EN 10025 B Vulcanized rubber profile CR 65 Sh/A CNR 10018 C A.M. clampØ16X15 ÷200 FeB 44K D Pavement

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

Expansion joint specifically designed for highway use within structures creating longitudinal movements of ± 15 (mm), vertical movements up to 10mm. It consists of an extruded rubber bellows, vulcanized to two 80x80x9 mm T-profiles and anchored to the slab by clamps of suitable diameter, placed at a centre distance of 240 mm. The extruded rubber, together with the steel profiles it is vulcanized to, makes up a water-tight system and seamlessly covers the entire width of the road bed. Water-tight capacity around the areas close to the joint is ensured by appropriate water-proof materials. POS. DESCRIPTION MATERIAL A 65x80x9 finger "T" profile S235JR EN 10025 B Vulcanized rubber profile CR 65 sh/a cnr 10018 C A.M. clamp Ø 16x150÷200 FeB 44K D Construction joint Fibre-reinforced cement mortar E Gutter Hypalon F "L" shaped drainage profile X5 CrNi 1810-UNI 8317 G Epoxy-resin mortar H Road surface

Request for a quoteResults for

T profiles - Import exportNumber of results

8 ProductsCountries

Company type