- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire and tube bending

Results for

Wire and tube bending - Import export

SCHMALE MASCHINENBAU GMBH

Germany

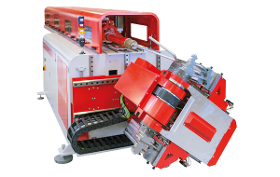

Finger bender technology on our X2000NC This is new and revolutionary! Do you know our X2000NC? Then you know the advantages of our variable, modular machine concept. In this new model, we have consistently transferred the finger bending technology of the SPEEDMAX to the X2000NC. This model now combines all the advantages of two bending worlds. By integrating the NC bending technology in combination with our rotary positioning pliers and the servo transfer, the X2000NC is now pushing material speeds to a whole new level. E.g.: Up to 40 parts per minute, each one with up to 6 bendings and 1 press operation is possible

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T, - Rod bending up to 16 mm, - Tube bending up to 30 mm; - sheet bending.

Request for a quote

ROKVELAS, UAB

Lithuania

- CNC bending up to 3000 mm 100T; - bending of threaded rods up to D12.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg Provide Tube Bending,Welding, Fabricating Services, Custom Stainless Steel,Copper, Aluminum Tube Bending Fittings. Our pipe bending & fabricating service is a cold machining technics for making pipe products, such as trolly handles & frames,chair brackets & backrest, Bathroom pipe faucet, Safe handrails in sports places, Horticultural accessories. That means all material should be in structure of pipe, then machining by pressing machines (pipe bender) to different flexual figures,and most pipe products need drill holes,pipe necking & expending, oblique cutting,etc. Generally pipes still need to be polished and surface treatment after machined, such as painting, powder coating, chrome plating,chemical polishing,anodizing. We specialize in pipe(tube) bent & fabricated products many years, can produce curved pipes from aluminum pipe, stainless steel pipe, carbon steel. if you want custom tube bending fittings from China, welcome send inquiry to us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube bending fittings from different, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

All of our products are customized by customer's drawing. Please feel free to send us your inquiry.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Mandrel bends kit,Mandrel bends

Request for a quote

MAHERAS LTD.

Bulgaria

We have 2 tube bending machines. One for small radii and one for large radii.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PI-METÁL

Hungary

We provide high quality CNC operated bending service We are able to bend on wide variety of angles tubes, pipes up to 81 mm diameter We can also bend square shaped profiles Processing pace is highly adjustable, that gives us ultimate control over the angle. Our ABM 76 CNC 1 Tube Machine bends tubes hidraulically up to 76 mm diameter with high quality This powerful machine provides convenience, prevents waste of time and increases efficiency, carrying out bending process consecutively and automatically with its advanced CNC feature

Request for a quoteResults for

Wire and tube bending - Import exportNumber of results

19 ProductsCompany type