PKO-SURA COMPANY - Manufacturer of industrial confectionery equipment

Russia

Manufacturer/ Producer

PKO-SURA COMPANY

Russia

Highly automated machines is designed for dosing of dough of various shapes and sizes without or with filling from different confectionery products on a baking pan by extrusion: -shortbread dough (hard or soft); -gingerbread dough; -dough for oatmeal cookies; -biscuit dough; -protein mass (souffle sweetmeat, pastille, marshmallow) The two-hopper mechanism of Сура СД and Сура СДУ depositors ensures the dosing of dough for double-color products or single-color filled products. All Сура С, Сура СД, Сура СДУ machines in standard version are equipped with mechanisms for rotation of draw plates and movement of the conveyor in the vertical plane. Сура СДУ universal depositor can be equipped with a diaphragm cutting unit where the diaphragms can be arranged both in single row and in staggered rows. Possibility to equip any Сура С, Сура СД, Сура СДУ machines additionally with a string cutting unit given that the frame of all machine s are equipped with the connection elements.

Request for a quote

PKO-SURA COMPANY

Russia

Depositors (extruders) are custom-manufactured depending on the needs of the Customer and the parameters of the oven. All projects are coordinated with the Customer and the oven manufacturers. The machine frame is manufactured in the following types: •U-shaped frame; •frame of intermediate section; •frame mounted in the oven tension station. Mechanisms and units of machines are specially designed considering the increased operating temperature and continuous equipment operation throughout the day. (for making various types of cookies, gingerbread, etc.)

Request for a quote

PKO-SURA COMPANY

Russia

It is designed for high-quality and uniform coating of various confectionery products with various types of glaze: chocolate fat sugar syrup, etc Due to the tank heating jacket and a mixing device, the glaze is heated to the operating temperature. The glaze is pumped into the glazing tank, and then the tank slide gates are opened and adjusted to obtain a straight, steady stream. The products to be glazed are placed on the feed conveyor and the conveyor is powered up. The products are transported on the large conveyor to the glazing area and then to the blowing area to remove excess glaze from the top. The bottom of the product is smoothed with the special rollers and then the products are transported to the cooling area. The glazing machine can be equipped with a decorator. Products can be glazed separately from the top, bottom or all sides. The machines for glazing with sugar syrup are manufactured considering some modifications necessary to operate the fast-hardening products.

Request for a quote

PKO-SURA COMPANY

Russia

Cooling of confectionery and bakery products before packaging is one of the most long-run (up to 5 hours or more) processes in production. The conveyor belt with the length of more than 300 m is necessary to transport the products during this time. Сура СKБ spiral conveyor is the best option for a conveyor system for cooling products for a long time. Due to the spiral geometry of the belt arrangement in space, it is possible to provide a large length of the belt in a minimum volume that essentially saves production space. In addition, the product is transported on a spiral conveyor belt as softly as possible, without rolling from one lay to another like in multilayered systems.

Request for a quote

PKO-SURA COMPANY

Russia

The СУРА-СП forming machine is designed for molding sugar cookies onto a belt with a further transportation to a wire-mesh plate of tunnel oven. The forming drum is one of the main units of the forming machine. It is a part of this machine and used for forming one type of cookies that have defined shape and pattern. At the request of the Customer, we can manufacture any number of drums with any pattern and shape of cookies. The patterns and shapes are chosen according to the catalogue.

Request for a quote

PKO-SURA COMPANY

Russia

The machine is intended to knead various types of high viscosity dough at confectionery and bakery enterprises: •gingerbread dough; •dough for doughnut products; •dough for sugar cookies; •dumpling dough, etc. The dough dish overturns through 120 degrees to unload the dough. All dangerous points of the machine are guarded. When the cover is open, the vane drive motor is automatically shut off. The feature of the dough-mixer is its powerful Z-shaped blades of stainless steel that enable to knead the tight dough gently. A variable frequency drive is used for smooth change of the blade rotation speed that makes it possible to use the machine for kneading crumpet dough.

Request for a quote

PKO-SURA COMPANY

Russia

Thermal cooker is intended to make syrup, marmalade, marshmallows, and chocolate glaze. It is designed for the preparation and heating of various confectionery masses: - chocolate glaze; - syrups; - fillings, jams; - marshmallow, marmalade; - scalded dough; - soups, etc. We produce cookers with volume of up to 2000 liters. The frame mixer with scrapers, the DN40 drain valve, temperature sensors for product and heat transfer agent, and heat insulation of cooking container are installed in the factory state. DN60, DN80 or DN100 drain valves are installed according to the Customer's choice. The cookers are equipped with a mechanism of automatic or manual reverse intended to make viscous masses, for example, choux pastry. In this case, the mass is discharged through the neck of the cooker. The reversible and more powerful mixer drive (at least 0.55 kW) is equipped at the bottom. It is possible to install a variable frequency mixer drive for smooth speed change.

Request for a quote

PKO-SURA COMPANY

Russia

Floor-mounted and desk-mounted Сура bakery ovens (making of nut-shaped or heart-shaped cookies, Viennese wafers) They are designed for baking of products from various confectionery masses: •shortbread cookies (nut-shaped cookies with caramelized milk, tart shells, heart-shaped cookies, cones, etc.) •butter (vanilla) heart-shaped cookies; •biscuit products (three-dimensional figures, Viennese wafers); •wafer sheet, wafer cones and rolls, three-dimensional raffaello wafers. The ovens are designed to be used both in small and large confectionery shops. The molds are made of aluminum alloy.

Request for a quote

PKO-SURA COMPANY

Russia

Bakery tunnel oven is modern equipment designed for baking various confectionery and bakery products on a movable belt (baking plate). We manufacture ovens with various types of conveyors: •wire-mesh conveyor belt (carbon or stainless); •chain conveyor with trays; •slatted conveyor belt with molds; •full metal conveyor belt. •The baking chamber is covered with stainless steel. Increased thermal insulation installed around the baking chamber reduces energy costs.

Request for a quote

PKO-SURA COMPANY

Russia

Starch molding machine is designed for production of fruit-jelly (including jelly candy), liqueur, fondant sweets and Korovka sweets by starch molding. The machine consists of a movable belt, a molding mechanism and a depositor mechanism. The tray is filled with starch which serves as a forming material. The confectionery mass is fed from the hopper to the dosing unit which performs deposition of sweets/molding the marmalade into molds formed in the starch layer.

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

KASAG SWISS AG

Switzerland

Glucose container with fittings for the preparation of glucose (grape sugar) The mobile KASAG glucose container is vacuum-tight and provided with a level detector and pump. Dough container with shredder for the baking industry The dough container with shredder is especially made for the sponge cake industry.

Request for a quote

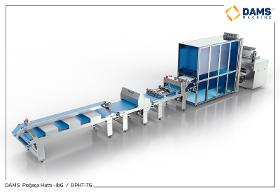

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free