- europages

- >

- Milling - steels and metals

- >

- SNK GMBH

- >

- products

SNK GMBH

Germany

Manufacturer/ Producer

SNK GMBH

Germany

◆Proven rigidity enables high precision and powerful cutting ・Dynamic rigidity achieved utilizing round column ・Static spindle head rigidity increased 1.4 times ・Thermal distortion minimized by advanced machine design and TDC software ◆User-friendly design ・Round quill design minimizes interference ・SNK's exclusive software allows easy 4 axes programming ・Highly customizable to meet customer demands ◆Increased user productivity ・Exclusive SNK software enhances machine productivity ・Remote machine monitoring available with IoT ◆Wide range of the bridge width can be applied to a variety of workpiece

Request for a quote

SNK GMBH

Germany

◆High-rigidity continuous 5-axis spindle head ・This machine is equipped with a highly rigid continuous 5-axis spindle head which enables the continuous machining of high-strength materials such as iron, titanium, and difficult-to-cut materials without using axis clamping mechanism ・High-rigidity square 450 mm ram and unique high torque rotating structure gives max. rotating torque of 6600 N・m for B and C axis

Request for a quote

SNK GMBH

Germany

◆44kW spindle enabling high-production (high-speed and high-power) cutting ・Double built-in motor is installed in the square ram ・High-level of productivity is enabled by the compact spindle with 44kW power and 1,200N·m torque ・Best-in-class chip discharge amount is achieved ◆Stable high-accuracy achieved by a high-rigidity structure ・High-rigidity and thermally symmetric angular columns employed ・The Z and W axes are driven by double ball screws driven at the center of gravity ・Center through cooling is provided as standard equipment for the Y and Z axes ball screws ◆"Easiness to use" taken into account ・The NC controlled W axis can be used as the machining axis and synchronized in operation with the Z axis ・Work accessibility is improved by the cylindrically shaped tip of square ram ・High customizability can cope with different needs

Request for a quote

SNK GMBH

Germany

◆The ultimate process-intensive multi-tasking machine that can process any workpiece ・High-precision machining is possible regardless of the work weight with a 5-axis configuration of tilting the spindle head and turning the table ・It also supports a wide range of processing from titanium to aluminum with various of spindle line up.

Request for a quote

SNK GMBH

Germany

◆An extra wide machining area ・Ample room for large workpiece in the 800mm Diameter × 2450mm Length, Max 2500kg ◆An easy to maneuver spindle head ・“Simultaneous Fitting” is achieved through the milling carriage's use of an ISO No.50 taper head spindle ・The spindle head combines high tooling rigidity ◆A powerful bed with 4 flat slide ・The highly rigidity bed provides a solid foundation for 4 flat side ways. ・Hight speed, high accuracy machining at its finest ◆machine every angle through an innovative combination of work rotation (C axis) and head tilt (B-A axis)

Request for a quote

SNK GMBH

Germany

・High-Speed machine realizing high efficient cutting of large size parts ・Enables to machine large-size and long-length aircraft parts in max. cutting feed rate 60m/min ・High-Speed Gantry cutting machine that can use from roughing to finishing

Request for a quote

SNK GMBH

Germany

◆Profiler with high-speed & high-power machining specification and high productivity for aluminum machining

Request for a quote

SNK GMBH

Germany

◆Vertical lathe & turning center that is developed based on the know-how of double column configuration ・Strong cutting is realized by having the 450 x 450mm ram ・It can be used not only as vertical lathe, but also as turning center with milling function and Y axis table movement that increase productivity

Request for a quote

SNK GMBH

Germany

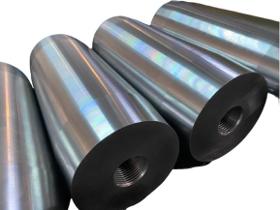

・Rigid structure with a flat, wide beds built for heavy cutting ・High-precision headstock with thermal balance function ・Adjustable control panel for operator convenience ・Ideal for a wide variety of turning processes ・Large diameter built-in center standard on tailstock. ・Ideal for long work processing with various follower rest attachments ・Maximum Swing Diameter: 1,600mm – 2,500mm (standard); up to 4,000mm ・Center Distance: 6,000mm (standard); customizable ・Workpiece Capacity: 70,000kg (standard); up to 400 Tons

Request for a quoteManufacturer/ Producer

Daimlerstrasse 18

73037 Göppingen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

METAL IN LTD

Bulgaria

The new CNC milling machines with vertical center with 3 and 5 axis machines give us a possibility to produce complex details with excellent quality. We work usual steel, stainless steel, aluminum, cast iron, brass. The maximum dimension of detail is 1200x600x600 mm, by 5 axis work ф320 mm. The maximum weight of the product is 1000 kg. The company possess universal milling machines, which are used for production of details with small series, repair of instruments, producing of single pieces

Request for a quote

METAL IN LTD

Bulgaria

The company have Milling machine with vertical center with 3 and 5 axis with CNC controls. Maximum size of details which we can work is 1200x600x600 mm and maximum weight – 1200 kg. We produce details from all types of steels, crude iron and non-ferrous metals. We possess with instrumental equipment for producing and repairing of devices and instruments, needed for different production of the company. The main details which we produce are: Pneumatic dividers for compressors Тooth wheels Hydraulic distributors Parts and components for mechanical engineering Details and units for the food industry

Request for a quote

DOGA MAKINA

Turkey

Pivots are at the center of any rotational movement. Exposed pivots often experience lug wear which occurs due to the clearance between the bore and the conventional pin. This is commonly repaired with line boring. What if there is a modern alternative to line boring that ensures no more lug wear and allows a greater capacity at any given size? Expander Pins are used on some of the world's biggest Original Equipment Manufacturers (Caterpillar, Komatsu, Volvo, John Deere etc) including installed equipment in a vast amount of industries.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Professional, Qualified and Experienced.. Best choice for your milling operation needs We are serving CNC milling operations to customers all around the world. Milling allowable part dimensions X:800 Y:500 Z:350 ± 0.01 mm Tolerance"

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free