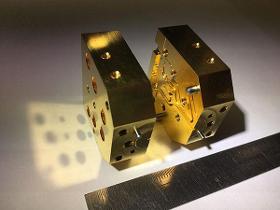

Nouvelle acquisition, le tour DMG Mori !

Product launch ・ 1 Jul 2021STEEC s’équipe d’une nouvelle technologie et pas des moindres, le DMG MORI NEF 400 ! Le tour DMG MORI est doté d’une stabilité et d’une précision hors pair pour réaliser des usinages parfaits. L’appareil connaît une fiabilité optimale qui garantit une sûreté de bon fonctionnement sur le long terme. En effet, la politique de la société est de toujours mettre au service de ses clients des technologies d’usinage toujours plus performantes afin de répondre aux exigences de l’infiniment précis. De plus, cette technologie est conçue pour pouvoir fonctionner en totale autonomie, ce qui assure un véritable gain de temps en ce qui concerne la production pour STEEC, mais également pour ses clients. STEEC et son tour DMG MORI NEF 400 attendent vos nouvelles demandes d’usinage de précision avec impatience !