- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inspection

Results for

Inspection - Import export

MINEBEA INTEC GMBH

Germany

The Checkweigher Flexus® meets the strictest requirements when it comes to hygienic design guidelines for packaged foods. A wide range of configurations ensure that every requirement is covered. Hygienic design for easy cleaning and the highest level of quality in your production operations Safety and reliability thanks to EMFC load cell technology The ideal solution every time – configure Flexus® for your application Easy to combine with metal detection technology Vistus®

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

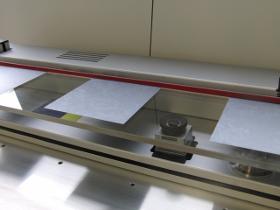

The LinearLevi-Inspectionmodule enables the inspection of substrates during the contactless transport. It is possible to check the quality of battery cells, foils, packaging, as well as wafers and chips without interrupting the transfer process. There is the opportunity to subsequently sort the substrates according to the inspection results. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. Features of the LinearLevi-Inspectionmodule: - Extendable - Various sizes - No particles due to no air turbulence - Double-sided inspection possible - High flatness, also for flexible substrates - Customizable according to customer specifications

Request for a quote

QUELLTECH GMBH

Germany

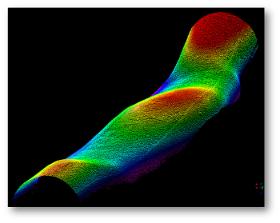

Four QuellTech Q6 3D- laser scanners are installed, mutually displaced by an angle of 90°. In this configuration, they are able to monitor the complete surface of the cable running through. It is important that the test does not lower the production speed, therefore very high sampling rates are required, supported by convenient data processing. The measured position of a defect is recorded in cable direction.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

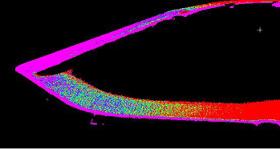

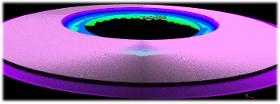

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

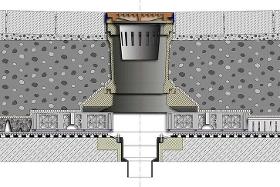

Optigrun Polymer Concrete Inspection Chamber PBK to be used as a drainage unit to guide surface water, corresponding to the respective requirements in the suitable composition, on stable substrates (e.g. underground garage decks) with a sufficiently high layer thickness.Inspection chamber for drivable surfaces Different gratings available for vehicular traffic and foot traffic Excess water can also be infed from the drainage level with the aid of TSK water conduits

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quote

MINEBEA INTEC GMBH

Germany

The X-ray inspection system Dylight guarantees extremely high levels of safety for your packaged food. This true ‘Plug and Play’ solution combines all functions in one compact unit. Extremely compact design Plug and Play: All functions in one unit Takes up only one metre of space in your production line Complete with separator and run-off container Maximum product safety thanks to the highest degree of detection sensitivity Intuitive, time-saving operation Easy installation and integration into networks

Request for a quote

MINEBEA INTEC GMBH

Germany

With Dypipe we guarantee you a new level of safety and flexibility in your production process of viscous and liquid products. The system can be equipped with various separators, connections, and mounting options that offer unmatched flexibility, making it the perfect solution for your production line. An innovative sample insertion system ensures specimen validation in live operation. For the high hygienic requirements in meat applications the Dypipe comes with an easy-open separator, specifically designed for this purpose. The X-ray inspection system is made of stainless steel and has a protection class of either IP 65 or IP 69. Several interfaces such as OPC UA, Ethernet IP and the Minebea Intec software for statistical process and pre-packaging control SPC@Enterprise pave the way to increased productivity.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

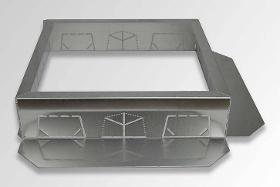

Special version of the Optigreen Triangle Maxi Inspection Cham-ber TMK with perforated intermediate floor to guide excess water from higher roof areas.For feeding and conveying excess water from rooftops located higher up to floors located lower down Conveys water through downpipes directly into a tie-in conduit with an open inlet at the top, e.g. in case of: Cascading drainage from smaller top floors, feeds roof drainage water from downpipes on façades into drainage levels of underground car parks or similar Can be connected to up to 6 WLP Plus and 3 TSK With perforated sheet metal intermediate partition Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Inspection chamber for use on greened or gravelled roof areas above drains in edge areas directly before any ascending structural components.Special inspection chamber for use over roof drainage outlets at the edge before ascending components, especially for outlets at the side through the fascia Chamber walls and cover with inlet slots, possible to connect 2 lengths triangle water conduit plus on three sides Chamber cover with inlet slots, compressive strength approx. 150 kg Insensitive to humid acid Reverse releasable 80 mm high

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Triangle Maxi Inspection Chamber TMK suitable for negative pressure drainage. Combinable with Triangle and TSK water discharge systems. Drainage capacity for 2 % roof pitch and profiles connected to all four sides: 24 l/s. Extendable in 50 and 100 mm increments.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Edge Inspection Chamber RKS 80 for use on greened or gravelled roof areas above drains on edge areas directly before any ascending structural components.Especially suitable for use around edges in front of rising components Above rainage outlets for green or gravelled rooftops Can be connected to 3 strands of WLP Plus Triangle Water Conduit Inspection lid with entry seals Insulation wedge profile released from the back Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Inspection Chamber TAR 250 to keep roof drainage outlets free with four connection options for TAR 80/250 or TAR 120/250.For pressure drainage and keeping drainage outlets free 4 possible connections for the drainage gutter TAR 80/250 or TAR 120/250 (preperforated openings) Chamber walls and lid with entry seals With aluminium chequered plate Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Combi Inspection Chamber TKS Plus is a control shaft for use as roof outlet inspection; includes base plate and cover. Extendable in 100 mm increments. Combinable with Triangle Water Discharge Profiles.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond Series of X-ray inspection systems is extremely versatile. Featuring 4 models it is able to cover the majority of applications for inspecting packaged products. With belt widths up to 800 mm it is ideal for multi-lane applications of up to 8 traces. Hygienic design, following EHEDG principles featuring sloped surfaces and curved edges allowing easy inspection and cleaning, resulting in considerable time and cost savings A wide range of standard possibilities for ensuring product integrity and quality including checking completeness, determining product mass and determining compartment mass Covering belt widths from 200 mm up to 800 mm 15" color touchscreen display Combining high detection sensitivity with low power consumption

Request for a quote

MINEBEA INTEC GMBH

Germany

VisioPointer® reliably automates inspection processes in food packaging lines using leading vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime, and optimize the production. As a plug and play vision solution, VisioPointer® makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond S side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond D side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MCS42-SEL-AL is a cost effective camera-based AOI system. This solution is optimized for economical and flexible inline inspection of the several production processes. The small and inexpensive system comes with a 42 megapixel, high-definition industry camera and a PC equipped with the powerful modusAOI software whose development includes professional experience of two decades. Characteristics: Single system for inspection of objects. Combination of diverse application tasks in the THT area which take place before a wave soldering or selective soldering oven. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The system comes with four 42 megapixel cameras and a high-performance control unit. LED lighting including LED control is also included in the delivery. The entire picture of the image analysis is orthogonally calibrated. Characteristics: This system can meet the toughest requirements for the inspection of bipolar plates in various production stages. The system has been adapted to the high requirements of the inspection of bipolar plates. The image acquisition time of approx. 2,5 seconds with a resolution of 24 um is outstanding. Inspection with the high-resolution system cameras is carried out using the tried and tested modusAOI software. Test possibilities: Position and minimum thickness of the graphite coating in the central area Checking the surfaces that should not be coated Coating contamination (graphite/screenprint) Testing of a defined target contour in screen print Damage to the metal at the edge (balcony) of the workpiece

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Manual, semi- or fully-automatic microscopes for spinneret inspection

Request for a quote

QUELLTECH GMBH

Germany

Plastic Mold Part (AC Controller) Inspection At this point the manufacturer is looking for scratches and chips and dimension specifications manually. In this respect manual inspection is not a repeatable or trustworthy method to guarantee steady quality of goods. It will be demanding for a human worker to detect this for a long period. QuellTech Solution Plastic Mold Parts are easily measurable materials for QuellTech scanners. Using the QuellTech Q4-120 Laser Line Scanner it is possible to obtain very precise reflection free 3D point clouds. A Software making necessary detections in 3D point clouds can effortlessly check dimensions and find scratches or any other defect which allows the manufacturer to automatically parse outparts that do not pass the tolerance levels.

Request for a quote

QUELLTECH GMBH

Germany

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

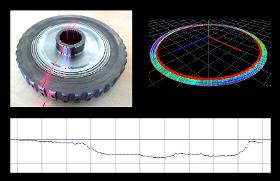

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quoteResults for

Inspection - Import exportNumber of results

149 ProductsCountries

- Germany (149)

- Berlin and region (2)

- Bonn, Düsseldorf and North Rhine and Westphalia (16)

- Frankfurt am Main and Hesse (10)

- Hamburg and region (14)

- Hannover and Lower Saxony (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (53)

- Potsdam and Brandenburg (21)

- Stuttgart, Freiburg and Baden-Wurtemberg (27)

- Weimar and Thuringia (4)

Category

- Sensors (38)

- Surface inspection systems (18)

- Light-emitting diode LED (14)

- Measurement - Equipment & Instruments (9)

- Metal detectors (9)

- Monitors, computer (8)

- Doors and gates, automatic and access control (7)

- Production and operational inspection (5)

- Machine vision system (5)

- Protective and work clothing (4)

- Monitoring and control equipment (3)

- Steel, structural (3)

- Automation - systems and equipment (2)

- Electronic components (2)

- Moulding, rubber - machinery (2)

- Tanks, metal (2)

- Video equipment, professional (2)

- Non-destructive tests (1)

- Weighing and dosing equipment (1)

- Measurement and control instruments (1)