- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- motor vibrators

Results for

Motor vibrators - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Dewatering screens are designed as linear vibrating devises for drainage of sand, plastic granules, kieserite, limestone, etc., even to depart insoluble contaminants from wash water or carrier liquids. Advantages & benefits double, specific screening performance of linear vibration with respect to flat screening easy replacement of screen decks low height Construction The design of the screen, depending on the requirements, in single or multi-deck construction. Possible drives are magnetic vibrators, unbalanced motors, exciters and circular vibrators. Dewatering screens are generally designed with top-mounted drives. Selection The sizing depends on: the material to be drained properties of the bulk material, such as bulk density, grain shape, size, size distinction Key figures The dimensions are determined by the task. Previously executed dimensions: length: up to 5,000 mm width: up to 2,800 mm throughput: up to 200 m³/h drives: magnetic vibrator, unbalanced motor, exci

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Hopper impact vibrators/bin activators errect bunker walls by periodic oscillations in shock and so the friction between the bulk and bunker wall (caking). They are just for knocking out of forms, for shaking of chutes and downpipes, for better emptying of containers and bulk materials from adhering to solve, for example in filters. The most common activators are unbalanced motors and magnetic vibrators. For special and heavy demands, there are impact vibrators available. Advantages & benefits magnetic impact vibrators excite the bunker walls with aligned linear oscillations. They have no "run out" and respond immediately after switching; the vibrational intensity can be adjusted at the control unit unbalanced motors have a rotating direction of force, they put the bunker wall in uniform, universally effective vibration large vibratory force at small dimensions robust and undemanding Construction In certain cases, a single drive can already act as an activator. If there i

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Vibrating table can be used both for compression and also for loosening bulk material. Typical applications are compacting of e.g. concrete mixes or the unstick/knock out of molds. There are two different approaches: The load to be vibrated, is set loosly on the table or firmly clamped to the vibrating device. Advantages & benefits variable, can be used for different tasks easy to regulate with magnetic vibrator Construction Compact design, with attached magnetic vibrator/s or unbalanced motors below the tabletop. Selection The sizing depends on: bulk material, such as bulk density, particle shape and internal friction the properties of the container, such as height, stiffness and sidewall Key figures length: up to 4,000 mm width: up to 2,000 mm payloads: up to 3,000 kg drive: magnetic vibrator, unbalanced motor, exciter

Request for a quote

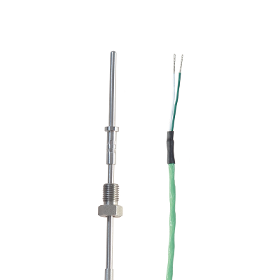

THERMA THERMOFÜHLER GMBH

Germany

This plug-in sheathing thermocouple is recommended for measuring the temperature in the exhaust gas flow. It is genuinely multipurpose, mounting with the cap nut means the thermocouple does not need to be rotated, which simplifies installation and fast replacement. In addition, it has “motor sports genes” such as vibration resistance, fast response time and high temperature resistance. The benefits: Vibration-proof Fast response time High temperature resistance (up to 1,200 °C) Various installation lengths can be supplied With cap nut Sheathed thermocouple NiCr-Ni, Type “K”, Class 1

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIAX - SCHMID & WEZEL GMBH

Germany

Hand piece ESB 3-50 (Basic) ***SE 50 Silent Grinder *** The new micro grinder with electric mickro-motor from BIAX - lightweight, low Vibration, extremly low noise! Technical data of hand Piece: Diameter: max. Ø 30 mm Length: 165 mm Weight without cable: 240 gr Run-out accuracy: < 0,02 mm Collets diameter: 3,0 mm (standard) / 2,35 mm (optional) Tool changing: Quick clamping Cooling: Enclosed (all models) Drive system: Brushless DC motor (all models) Technical Data: Speed range: 1.000 - 50.000 rpm Operating Voltage: 100 - 240 Volts Rated frequency: 50/60 Hz Power: 150 Watts Overload protection: Eliminates waiting time when switching back on Direction of Rotation: Switch between clockwise and anti-clockwise rotation

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Lightweight, with a proven, low-vibration SRD 355 motor; it ensures high precision and a long operating life. Its lightness and ergonomic form means that you don‘t tire quickly and allows you to carry out delicate deburring. It can be guided like a pencil and is also qualified for fine grinding, milling and engraving operations.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Hand piece ESS 3-50 (Slim) ***SE 50 Silent Grinder *** The new micro grinder with electric mickro-motor from BIAX - lightweight, low Vibration, extremly low noise! Technical data of hand Piece: Diameter: max. Ø 29 mm Length: 162 mm Weight without cable: 240 gr Run-out accuracy: < 0,02 mm Collets diameter: 3,0 mm (standard) / 2,35 mm (optional) Tool changing: Quick clamping Cooling: Enclosed (all models) Drive system: Brushless DC motor (all models) Technical Data: Speed range: 1.000 - 50.000 rpm Operating Voltage: 100 - 240 Volts Rated frequency: 50/60 Hz Power: 150 Watts Overload protection: Eliminates waiting time when switching back on Direction of Rotation: Switch between clockwise and anti-clockwise rotation

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The range of external vibrators from Knauer Engineering includes normal frequency, high frequency and oscillating vibrators in various executions for applications in the construction and concrete industry as well as in other industries. Besides the proven vibrator system of Losenhausen, Knauer Engineering also offers now a considerably vibrator program for multi-purpose working areas. Applications are used in Construction industry, Industry of building materials, Mining-, Chemical-, Packaging and food industry, mechanical engineering as well as quality inspection and quality assurance.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

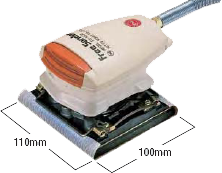

Superlight, Quiet New lowvibration sander Small and Lightweight for Comfort and Convenience Free Sander fits the hand like a glove. It's humanengineered to less tiring over longer periods of operation for big jobs, and compact enough to permit working easily in corners and other spots. Minimized Hand Vibration The turbine motor of FS100C and the singleball air motor of FS50A are mounted directly onto the sanding pad to minimize the discomfort of hand vibration and lessen operator fatigue caused by vibration. This along with excellent control results in a finer finish on all surface materials.

Request for a quote

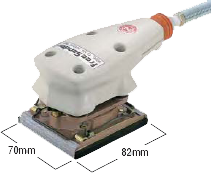

NITTO KOHKI EUROPE GMBH

Germany

Superlight, Quiet New lowvibration sander Small and Lightweight for Comfort and Convenience Free Sander fits the hand like a glove. It's humanengineered to less tiring over longer periods of operation for big jobs, and compact enough to permit working easily in corners and other spots. Minimized Hand Vibration The turbine motor of FS100C and the singleball air motor of FS50A are mounted directly onto the sanding pad to minimize the discomfort of hand vibration and lessen operator fatigue caused by vibration. This along with excellent control results in a finer finish on all surface materials.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

OUR ENTRY-LEVEL MODEL – EFFICIENT AND COST EFFECTIVEThe circular vibrators of the CF series are a perfect and simple introduction to mass finishing. The seven different configurations, with a range of different bowl sizes, offer excellent efficiency and maximum cost effectiveness. The CF circular vibrators are easy to operate and can be expanded with accessories for sound deadening or metering, for example. PROCESSING AND SEPARATION – SMOOTH MASS FINISHING The work bowl with an evenly rising floor is perfect for processing your workpieces, as the zero-maintenance vibration flange motor works at two different speeds. The pneumatic separator flap and long separation zone allow you to gently separate your workpieces from the abrasive media. This creates a smooth mass finishing process with excellent results.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The PALLMANN rener system produces high quality bers from chips, saw dust, shavings, and annual plants for MDF, HDF, and insulation board production. PALLMANN supplies complete plants consisting of perfectly coordinated components to ensure the highest ber quality with minimal energy input. High quality ber production for MDF, HDF and insulation board plants with PALLMANN rening systems Chip bin for pre-steaming of chips: The closed design of the bin with downward tapering base is equipped with vibrating motors to ensure a continuous discharge. Circular steam injection results in perfect pre-tempering of the chips. Integrated load cells allow the online presentation of the lling level of the chips inside the bin. Plug screw: The extremely heavy and robust plug screw feeds the chips reliably into the digester and squeezes out excess water by doing so. The position compensation, caused by the thermal expansion of the digester

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The PALLMANN refiner system produces high quality fibers from chips, saw dust, shavings, and annual plants for MDF, HDF, and insulation board production. PALLMANN supplies complete plants consisting of perfectly coordinated components to ensure the highest fiber quality with minimal energy input. Chip bin for pre-steaming of chips: The closed design of the bin with downward tapering base is equipped with vibrating motors to ensure a continuous discharge. Circular steam injection results in perfect pre-tempering of the chips. Integrated load cells allow the online presentation of the filling level of the chips inside the bin. Plug screw: The extremely heavy and robust plug screw feeds the chips reliably into the digester and squeezes out excess water by doing so. The position compensation, caused by the thermal expansion of the digester, can be safely implemented by the special design of the robust base frame. Due to the extended high-compression zone, a very even moisture...

Request for a quoteResults for

Motor vibrators - Import exportNumber of results

15 ProductsCountries

Company type