- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inspection

Results for

Inspection - Import export

MINEBEA INTEC GMBH

Germany

The Checkweigher Flexus® meets the strictest requirements when it comes to hygienic design guidelines for packaged foods. A wide range of configurations ensure that every requirement is covered. Hygienic design for easy cleaning and the highest level of quality in your production operations Safety and reliability thanks to EMFC load cell technology The ideal solution every time – configure Flexus® for your application Easy to combine with metal detection technology Vistus®

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The Focovision by Transmission SPF-3 is used in optical laboratories where the lenses are mounted into frames. It is connected to the computer network, from which it receives the nominal values of the prescription lens. Its main advantages are repeatability, accuracy, and easy calibration. It measures the lens optical power by using a light beam perpendicular to the concave lens surface at a certain wavelength (546 nm or 587 nm) and by measuring in all directions (360 degrees). In addition, it is equipped with a frame positioning device and has a user friendly interface; permitting an operator to learn how to perform the complete lens control of the mounted lenses with little training required. Positioning assistance: The FOCOVISION display provides assistance to the operator to help them position the frame and lens to be measured properly, creating a user friendly and fast process. The positioning target, displayed at every step of the procedure, and operator instructions projected

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The Control Unit for Prescription Lenses is a machine dedicated to prescription labs producing at least 1000 jobs per day. This multi-functional automatic machine is the only one on the market to combine the lens inspection according to the ISO/ANSI standards of all lens types, the mapping of freeform lenses, the flexible digital inking and the laser engraving. The measurement data exported by the machine are very useful for an effective process control. The Control Unit for Rx lenses is the perfect tool to increase your customer satisfaction, by improving your quality and optimizing the delivery times.

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The control unit for single vision semi-finished lenses (MCSFU) is the perfect tool for the free-form laboratories. With a capactity of more than 360 lenses an hour, the MCSFU detects any picking, supply or data error. It measures, accurately and contactless, the radius of the front curve of the single vision semi-finished lenses. The measured data are directly transmitted to the LMS (Lab Management System) software so that the measured data can be taken into account for the calculation.

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The Focovision by Transmission SPV-3 is used in prescription laboratories. It is connected to your computer network, from which it receives the nominal values of the prescription lens. Its main advantages are repeatability, accuracy, easy calibration, and especially its visualization system of the semivisible marks or the upper segment line corner of the addition. This system permits an accurate positioning on the different control points without any lens marking. It measures the lens optical power by using a light beam perpendicular to the concave lens surface at a certain wavelength (546 nm or 587 nm) and by measuring in all directions (360 degrees). In addition, it has a user friendly interface permitting an operator to learn how to perform the complete lens control (far view, prism reference point, near view, thickness, shape, etc.) with little training required. Minimal training required Very high measurement speed Flexibility (configurable procedures, easy to adapt, any toleran

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The Dual LensMapper, integrated in this unit, gives a mapping of the prescription lens (freeform or conventional) and calculates FOA optical power at the reference points (FV, NV). For the freeforms, it compares the expected design to the real lens and displays an error map. A Go/NoGo decision is made, based on the error map and the list of criteria defined by the lab. Because the A&R AutoMapper is task specific, and the system has a small footprint, you can easily integrate it into the lab, either directly after the surfacing or in the final control (also suitable for checking the cut lenses). The AutoMapper is an excellent investment for a modern lab with a rapid payback! 100 % production control just after surfacing --> direct feedback on production* control of the cut lens - in case of remote edging Non contact measurement Correction of eventual R/L inversion Integrated Dual LensMapper : measurement of free form and conventional progressive lenses Control of power, cyl.

Request for a quote

ALUMINIUM GIETERIJ OLDENZAAL B.V.

Netherlands

Our modern inspection and testing equipment allows us to inspect the cast products completely according to your requirements before we deliver them to you. We offer: Inspection of materials (both chemically and mechanically) Delivery under certificate Measurements reports Wall thickness measurement Radiography Penetrant inspection Pressure and leakage tests Endoscopic Ultrasonic Microscopic Hardness measurement 3D scan & 3D-cad comparison

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The ProMapper is the A&R table-top solution to provide state-of-the-art optical inspection according to the industry standards (ISO/ANSI), totally independent from the operator. In addition, it supplies freeform surface evaluation based on the A&R Error Map technology, making sure that no surface defect is shipped to the customer. Based on the Error Map, surface quality features like the GMC (Global Mapping Criteria) are evaluated and constitute extremely relevant inspection data for process control applications (Statistical Process Control).

Request for a quote

ZS-HANDLING TECHNOLOGIES GMBH

Germany

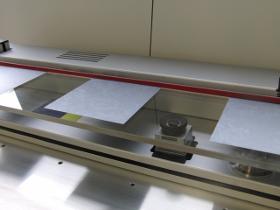

The LinearLevi-Inspectionmodule enables the inspection of substrates during the contactless transport. It is possible to check the quality of battery cells, foils, packaging, as well as wafers and chips without interrupting the transfer process. There is the opportunity to subsequently sort the substrates according to the inspection results. The application can be delivered in different versions. For example, combinations with the UltraLevi-Desk for contactless transport are possible. Features of the LinearLevi-Inspectionmodule: - Extendable - Various sizes - No particles due to no air turbulence - Double-sided inspection possible - High flatness, also for flexible substrates - Customizable according to customer specifications

Request for a quote

ROBOTNIK

Spain

The autonomous XL-GEN can be configured in different ways: without arm, ready to integrate an arm from Kinova or with 7 or 6 DOF arm with the option to integrate a 2 or 3 finger gripper. Due to the low power consumption of the arm, this mobile platform has an autonomy of up to 10 hours. Furthermore, XL-GEN, that uses open architecture and modular control ROS, can mount different sensors as lasers and cameras, among others. The robot has two possible kinematic configurations. The omnidirectional configuration mounts mecanum wheels on an independent suspension system. The mecanum wheels can be easily replaced by conventional wheels (rim mount), thus allowing easy switch from the indoor omnidirectional configuration to the versatile skid-steering configuration, both indoors and outdoors. XL-GEN has been designed for several research applications in fields like inspection, medicine, logistics or remote monitoring.

Request for a quote

SONATEST LTD

United Kingdom

The Masterscan D-70 offers the inspector a fully capable and functional set of tools and software for inspection across all applications. Capabilities include encoded B-Scan, Advanced Thickness logging and Dryscan capability in a portable enclosure. Features Include: Customisable & Inituitive Menus Split DAC/AVG/DGS Angle Measurement Mode. Dryscan capability. Configurable on-board software. Field Upgradeable. Encoded B-Scan A-Scan Fade. 4GByte on-board memory. USB Interface for PC import/export. Video Output for training.

Request for a quote

QUELLTECH GMBH

Germany

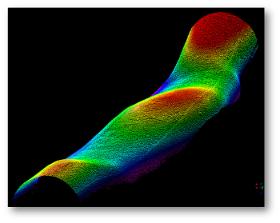

Four QuellTech Q6 3D- laser scanners are installed, mutually displaced by an angle of 90°. In this configuration, they are able to monitor the complete surface of the cable running through. It is important that the test does not lower the production speed, therefore very high sampling rates are required, supported by convenient data processing. The measured position of a defect is recorded in cable direction.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

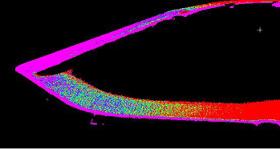

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin: China Model Number: TXR-1630SO Power: Electronic Certificate: ISO/CE Application: Food Processing Industry Color: Silver gray Warranty: 12 Months Power supply: 110V - 220V Material: SUS 304 Stainless Steel Supply Ability: 50 Case/Cases per Month Payment term:T/T,L/C Lead time:15-30days Package:standard exporting package Port of shipment:China

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

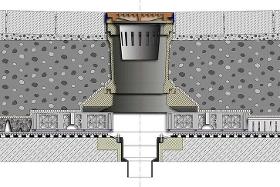

Optigrun Polymer Concrete Inspection Chamber PBK to be used as a drainage unit to guide surface water, corresponding to the respective requirements in the suitable composition, on stable substrates (e.g. underground garage decks) with a sufficiently high layer thickness.Inspection chamber for drivable surfaces Different gratings available for vehicular traffic and foot traffic Excess water can also be infed from the drainage level with the aid of TSK water conduits

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

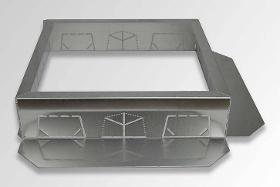

FTK Förderband Technik Kilian GmbH inspection and safety hatch dust proof inspection hatch allows inspection of and access to chutes, transfer points and other housings for maintenance and inspection of belt scrapers or for other service requirements Different sizes All hatches have a safety grille. Durable construction for retrofits or new systems

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIGRÜN INTERNATIONAL AG

Germany

Inspection chamber for use on greened or gravelled roof areas above drains in edge areas directly before any ascending structural components.Special inspection chamber for use over roof drainage outlets at the edge before ascending components, especially for outlets at the side through the fascia Chamber walls and cover with inlet slots, possible to connect 2 lengths triangle water conduit plus on three sides Chamber cover with inlet slots, compressive strength approx. 150 kg Insensitive to humid acid Reverse releasable 80 mm high

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Edge Inspection Chamber RKS 80 for use on greened or gravelled roof areas above drains on edge areas directly before any ascending structural components.Especially suitable for use around edges in front of rising components Above rainage outlets for green or gravelled rooftops Can be connected to 3 strands of WLP Plus Triangle Water Conduit Inspection lid with entry seals Insulation wedge profile released from the back Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Inspection Chamber TAR 250 to keep roof drainage outlets free with four connection options for TAR 80/250 or TAR 120/250.For pressure drainage and keeping drainage outlets free 4 possible connections for the drainage gutter TAR 80/250 or TAR 120/250 (preperforated openings) Chamber walls and lid with entry seals With aluminium chequered plate Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Combi Inspection Chamber TKS Plus is a control shaft for use as roof outlet inspection; includes base plate and cover. Extendable in 100 mm increments. Combinable with Triangle Water Discharge Profiles.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Triangle Maxi Inspection Chamber TMK suitable for negative pressure drainage. Combinable with Triangle and TSK water discharge systems. Drainage capacity for 2 % roof pitch and profiles connected to all four sides: 24 l/s. Extendable in 50 and 100 mm increments.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The MCS42-SEL-AL is a cost effective camera-based AOI system. This solution is optimized for economical and flexible inline inspection of the several production processes. The small and inexpensive system comes with a 42 megapixel, high-definition industry camera and a PC equipped with the powerful modusAOI software whose development includes professional experience of two decades. Characteristics: Single system for inspection of objects. Combination of diverse application tasks in the THT area which take place before a wave soldering or selective soldering oven. Typical tests include confirmation of the mechanical assembly, presence, placement and orientation of plugs, stickers, fixings, reading of barcodes and data-matrix codes.

Request for a quote

MODUS HIGH-TECH ELECTRONICS GMBH

Germany

The system comes with four 42 megapixel cameras and a high-performance control unit. LED lighting including LED control is also included in the delivery. The entire picture of the image analysis is orthogonally calibrated. Characteristics: This system can meet the toughest requirements for the inspection of bipolar plates in various production stages. The system has been adapted to the high requirements of the inspection of bipolar plates. The image acquisition time of approx. 2,5 seconds with a resolution of 24 um is outstanding. Inspection with the high-resolution system cameras is carried out using the tried and tested modusAOI software. Test possibilities: Position and minimum thickness of the graphite coating in the central area Checking the surfaces that should not be coated Coating contamination (graphite/screenprint) Testing of a defined target contour in screen print Damage to the metal at the edge (balcony) of the workpiece

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

MINEBEA INTEC GMBH

Germany

VisioPointer® reliably automates inspection processes in food packaging lines using leading vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime, and optimize the production. As a plug and play vision solution, VisioPointer® makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quoteResults for

Inspection - Import exportNumber of results

271 ProductsCountries

Company type

Category

- Sensors (38)

- Surface inspection systems (21)

- Light-emitting diode LED (14)

- Metal detectors (13)

- Monitoring and control equipment (11)

- Production and operational inspection (10)

- Measurement - Equipment & Instruments (10)

- Machine vision system (8)

- Monitors, computer (8)

- Doors and gates, automatic and access control (7)

- Medical and surgical optics - instruments (7)

- Electricity generators (4)

- Non-destructive tests (4)

- Protective and work clothing (4)

- Safety equipment, work (4)

- Weighing and dosing equipment (4)

- Automation - systems and equipment (3)

- Labelling machines (3)

- Optical measuring equipment (3)

- Steel, structural (3)