- europages

- >

- Magnets

- >

- ASSFALG GMBH

- >

- products

ASSFALG GMBH

Germany

Manufacturer/ Producer

ASSFALG GMBH

Germany

The manual magnet transporter magnetizes and demagnetizes with the push of a button. Nevertheless, it holds like a permanent magnet. Oily, sharp workpieces or hot burn cutting parts can be quickly moved with this. The HL 60-CEL has an ergonomic extended handle bar to pick up components on the ground. It is switched through a remote control in the handle. All technical data can be found in the .pdf file.

Request for a quote

ASSFALG GMBH

Germany

For decades, the crane magnetic transporters from the SH series have been used throughout Europe as the optimal solution for the crane transportation of sheets, even with larger sizes. Contrary to normal load lifting magnets, crane magnet transporters have a flatter magnetic field allowing them to take up thinner workpieces such as sheets already from 3 mm thickness. They are ideal for horizontal and vertical transport and extremely efficient, but they must be separated from the workpiece using a jacking fixture. With bend presses, they are an interesting alternative to mechanical carrying clamps for metal sheet guiding. The mobile crane suspension makes it possible to lift and move heavy metal sheets. The SH series is used where sheets have to be lifted, transported and moved with a crane, for example, in a material warehouse.

Request for a quote

ASSFALG GMBH

Germany

The positioning drawbar has a gradual flexible range of +/- 60°. The adjustment occurs easily by loosening the hand brake. A wireless remote control can be installed directly on the handle to switch the magnets on and off. Other remote controls to control cranes are possible on request. All technical data can be found in the .pdf file.

Request for a quote

ASSFALG GMBH

Germany

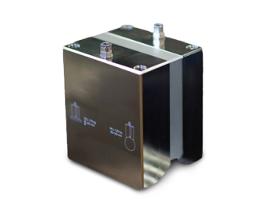

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The AR series was specifically designed for workpieces that do not have any level contact surfaces. They are only switched on or off with a short compressed air impulse. Workpieces with level, flat, round or irregular surfaces are transported without effort. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. The magnets are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The AY series was developed specifically for sheet handling. They can measure technically with vacuum systems in the thin sheet area and are much more efficient. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

These magnets can be individually adjusted to different tasks. They are only switched on with a short compressed air impulse between 5 and 8 bar. They are low-maintenance and have very fast switch-on times. Individual solutions with multiple parallel-controlled magnets simplify your lifting task or work process. It is not just used in fully automatic systems, but rather also for the simples manual lifting processes.

Request for a quote

ASSFALG GMBH

Germany

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This magnetic clamping plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces. This protects the milling spindle as well as your tools, increases process safety and extends the service life.

Request for a quote

ASSFALG GMBH

Germany

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This magnetic clamping plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces. This protects the milling spindle as well as your tools, increases process safety and extends the service life.

Request for a quoteManufacturer/ Producer

Buchstraße 149

73525 Schwäbisch Gmünd - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

PARSMEGA MAKINA

Turkey

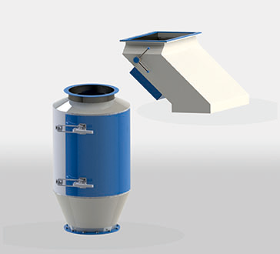

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free