- europages

- >

- Magnets

- >

- ASSFALG GMBH

- >

- products

ASSFALG GMBH

Germany

Manufacturer/ Producer

ASSFALG GMBH

Germany

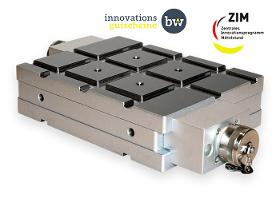

The patented EPM magnetic clamping plates *** Patent-No. EP1874504 *** have a solid steel surface and are therefore significantly more resistant than conventional plates with epoxy resin against hot chips, coolant and other processing influences. The workpiece is clamped on the EPM magnetic clamping plate MAGNASLOT within seconds through an impulse current. This combo plate allows for 5-side processing of your workpieces in only one clamp. This reduces equipping times to a minimum and increases productivity. Conventional machine vices or clamping claws can be used to clamp non-ferrous workpieces. Through the use of pole extensions, which adjust to the workpiece surface, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. The magnet field from the MAGNASLOT magnetic clamping plate guarantees low-vibration clamping of your workpieces.

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Doublemag magnet clamping elements. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface. Several Doublemags can be combined to process large parts.

Request for a quote

ASSFALG GMBH

Germany

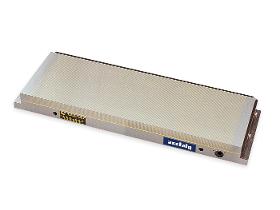

This highly accurate magnetic clamping plate is used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microfine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

These highly accurate Magnet Sinetables are used for grinding work as well as for eroding. It allows for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thin and fine workpieces. The permanent Microsine magnetic clamping plate is preferably used if a flat and light construction is needed during grinding, eroding or milling. A complete, fine transverse pole distribution (steel/brass) guarantees a consistent holding force over the entire width up to the longitudinal sides. This clamping plate can be activated through a hexagonal switch lever. They are available in two versions: either single-pivotable via the longitudinal axis or double-pivotable via the longitudinal and transverse axis. Gauge blocks can be used to set the tilt angle precisely up to 45 °. The magnet Sinetable is suitable for accurate grinding of workpieces with nonparallel surfaces. Individual designs can be created on request.

Request for a quote

ASSFALG GMBH

Germany

These permanent magnetic clamping plates Permamax from ASSFALG are suitable for heavy clamp-lifting processing. These Permamax permanent magnetic clamping plates can be used for milling, drilling, grinding and slicing. Considerable holding forces are still achieved on uneven and rough surfaces. They allow for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thick and large workpieces. A complete, wide transverse pole distribution (steel/brass) guarantees consistently high holding force over the entire width up to the longitudinal sides. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

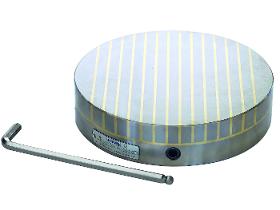

These Permamax permanent magnetic chucks from ASSFALG are suitable for heavy clamp-lifting processing. These Permamax permanent magnetic chucks can be used for milling, rotating and grinding. Considerable holding forces are still achieved on uneven and rough surfaces. They allow for universal clamping of small, medium and large workpieces of any thickness, however, they are best suitable for thick and large workpieces. A complete, wide transverse pole distribution (steel/brass) guarantees consistently high holding force over the entire width up to the longitudinal sides. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

These Neostar magnetic chucks can be used universally, in particular for internal cylindrical grinding, rotating and hard rotating. The uniform radial pole division offers significant advantages compared to magnetic chucks with parallel pole division in particular when processing rings and discs that are difficult to hold as well as sleeves. A higher stability and stiffness can be achieved through radial pole division in particular with larger diameters. A centric through-hole can be incorporated. These clamping plates can be activated through a hexagonal switch lever.

Request for a quote

ASSFALG GMBH

Germany

The EPFlux magnetic clamping plate has no remanence (residual magnetism) upon deactivation. Highly alloyed and hardened workpieces can be easily loosened from the magnetic clamping plate. Highest grinding precision is achieved, because the plate is not heated up. Not heated up means that there are no expansion and deformation to the workpieces to be processed. The electropermanent magnetic clamping plate is the ideal clamping plate for precision grinding machines. The laminated surface made of brass and steel and the solid steel body guarantee magnetic holding force as well as unique hardness over the entire surface. With the EPFlux magnetic clamping plate, large and small workpieces can be evenly clamped. The magnetizing and demagnetizing occurs through a short power pulse within seconds.

Request for a quote

ASSFALG GMBH

Germany

Whether while milling (rough and finish machining), drilling, sawing, welding or assembling, the EPM modules or module systems offer a large selection of clamping options, for example, to clamp during edge milling or deburring (without mechanical clamping equipment) or for the simple and quick fastening of workpieces during assembly. Workpieces can be easily and quickly fastened with the Triplemag magnet clamping elements. The Triplemag series has additional positioning magnets, ensuring a constant position on the machine table and which are separately switched. Through the use of pole extensions, any unevenness on the workpiece can be compensated for and a deformation of the workpiece can be prevented. Using pole extensions, plane-parallelism of up to 0.01 mm is possible on the workpiece. The processing runs without vibration and an even distribution of holding force is guaranteed throughout the entire ferrous clamping surface.

Request for a quote

ASSFALG GMBH

Germany

The uniform radial pole division offers significant advantages compared to magnetic chucks with parallel pole or square pole division in particular when processing rings and discs that are difficult to hold as well as sleeves. A higher stability and stiffness can be achieved through radial pole division in particular with larger diameters. A centric through-hole can be incorporated in the area that has no active magnet. The electropermanent magnetic chuck EPMradial from Assfalg is ideal for clamping big, rotationally-symmetrical workpieces (for example, bearing ring processing) starting at a diameter of 400 mm, in particular on rotating and milling machines as well as drilling machines without distortion. The EPMradial electropermanent magnetic chuck permits an extreme takeoff during the hard processing of rings. The highest precision is achieved during grinding work.

Request for a quoteManufacturer/ Producer

Buchstraße 149

73525 Schwäbisch Gmünd - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

PARSMEGA MAKINA

Turkey

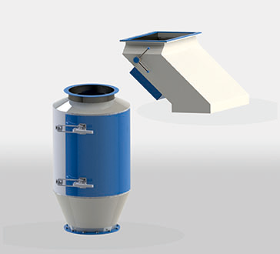

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free