- europages

- >

- Magnets

- >

- ASSFALG GMBH

- >

- products

ASSFALG GMBH

Germany

Manufacturer/ Producer

ASSFALG GMBH

Germany

The ASO 310 is used for deburring and rounding off edges on workpieces made of steel, stainless steel, aluminum and other materials. With the standard ball bearing, it is suitable for processing drill holes and openings starting with an internal diameter of 12 mm and a sheet thickness >8mm. With the optionally available stop collar for thin sheets, drill holes and internal diameters starting at 14 mm and a sheet thickness of >2mm can be processed. The edge break with R1 or R2 is only possible in combination with the stop collar for thin sheets. The compact construction and the low weight offer wonderful ergonomics. The machine is equipped with a powerful and reliable pneumatic drive. The chamfer size can be set through the rotary plate.

Request for a quote

ASSFALG GMBH

Germany

The ASO 312 is for the chamfering and rounding off of workpieces with straight edges. The edge break with R2 - R4 is only possible by replacing the turning plate. A secure and simple handling is possible through the prismatic guide and additional handle. This helps us achieve a particularly clean and vibration-free chamfer quality. The compact construction and the low weight offer wonderful ergonomics. The machine is equipped with a powerful and reliable pneumatic drive. The chamfer angle can be gradually set between 15 - 45°.

Request for a quote

ASSFALG GMBH

Germany

The ASO 313 is for the chamfering and rounding off of workpieces with straight edges. The edge break with R2 - R4 is only possible by replacing the turning plate. A secure and simple handling is possible through the prismatic guide and additional handle. This helps us achieve a particularly clean and vibration-free chamfer quality. The compact construction and the low weight offer wonderful ergonomics. The machine is equipped with a powerful and reliable pneumatic drive. The chamfer angle can be gradually set between 15 - 45°. Advantages: For 15 - 45° chamfers and for rounding edges Secure handling through prismatic guide and handle Reliable electric motor Insert milling cutter for efficient chamfering

Request for a quote

ASSFALG GMBH

Germany

The SMA 20-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 7 mm is possible in NE metals and a chamfer width of up to 4mm in steel. In addition to this, a radius processing of 1.2mm and 2.5mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The processing of drill holes is already possible starting at a diameter of >20mm.

Request for a quote

ASSFALG GMBH

Germany

The SMA 40-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 16 mm is possible in NE metals and a chamfer width of up to 12mm in steel. In addition to this, a radius processing of 1.2mm to 8mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 40 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quote

ASSFALG GMBH

Germany

The SMA 50-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 20 mm is possible in NE metals and a chamfer width of up to 15mm in steel. In addition to this, a radius processing of 1.2mm to 8mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm.

Request for a quote

ASSFALG GMBH

Germany

The SMA 60 is available in an electrical, compressed-air or high-frequency design. The machine is designed for handling steel, aluminum, copper and plastics. In NE metals and steel up with a tensile strength of 600N/mm², a chamfer width of up to 30mm is possible. In addition to this, a radius processing of 1.2mm to 15mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The cutter heads are available for chamfer angles between 0 - 80°. The processing of drill holes is already possible starting at a diameter of >28mm. Advantages: Booster technology for a higher material removal rate Spring technology for higher service life of cutting inserts Processing chamfers, radii on sheets, containers, inner and outer edges, contours and drill holes Replaceable cutter head for different chamfer angles 0 - 80° Easy and vibration-free work

Request for a quote

ASSFALG GMBH

Germany

With its placement prism on wheels, the ASO 760 is ideal for welded seam preparation for straight and large workpieces. Different welding chamfers can be produced through the angle setting from 0 - 60°. The two-disc chamfer with the wonderful and patented 8 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 18mm is possible here. Round materials or tubes starting with an external diameter of 150mm can be chamfered through an optionally available pipe chamfering device. Advantages: Processing chamfers on sheet metal, containers, outer edges Angle adjustment from 0 - 60° Up to 8-times usable turning cutting plates Sturdy and durable machine Good guide through two-hand operation Optional chamfering device starting at Ø150mm Controlled flying chips

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 2 mm thickness. The sturdy cast iron casing, the hardened and sanded guide rails, the speed regulation and the integrated chip box convince in every regard. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. A chamfer width of up to 10 mm is possible in NE metals and a chamfer width of up to 5mm in steel. Hardened workpieces, HSS and hard metal materials can be processed through optional CBN and diamond grinding discs. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 5 mm thickness. The hardened and sanded guide rails must be turned for smaller and thinner workpieces starting with a thickness of 2 mm. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clean and constant chamfering. A chamfer width of up to 12 mm is possible in NE metals and a chamfer width of up to 10mm in steel. The cutting edge length of the cutting inserts can be used 100% thanks to the innovative axially adjustable motor shaft. The ASO 650-WSL has speed regulation that is very useful when processing aluminum or stainless steel and a gradual angle adjustment in a range from 15-45°. A radius processing from R1.2 to R6 is possible with different cutting inserts. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools.

Request for a quoteManufacturer/ Producer

Buchstraße 149

73525 Schwäbisch Gmünd - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

PARSMEGA MAKINA

Turkey

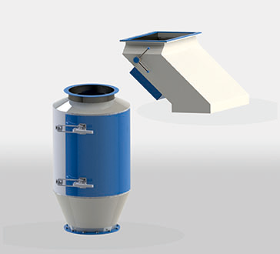

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free