AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Manufacturer/ Producer

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Unbalance exciters are designed for producing linear motion for medium and large size vibrating machines operating in many industrial processes. The design is engineered for safe operation in continual operation with 100% centrifugal force. In order to archieve higher working moments it is possible to use number of exciters parallel in line. Advantages and benefits powerful drive for higher working moments and wide performance range extremely durable smooth running low maintenance in continual operation economical and long service life low noise level operation Construction and operation mode The AViTEQ unbalance exciters are made of low vibration cast housing. Two shafts mounted in four spherical roller bearings are synchronized by two gears . The mounted on the shaft ends and synchronous forced unbalanced weights are driven by an external drive and produce unidirectional vibrations . The regulation of the static moment can be carried out by some additional weights . Key fi

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ - Small part conveyor drive is used everywhere fine-grained bulk materials and not too unwieldy mass parts must be delivered, conveyed, dosed, added or assigned from storage tanks. AViTEQ has led the way in producing these devices and drives in Germany on a highest level standard. Advantages and benefits High level of conveying capacity with compact dimensions operationally safe in continuous employment No influencing of the conveying speed with different loading of the user device (conduit, trough, rail). Conformity with all EC Guidelines which affect the drives available for explosion-endangered spaces (ATEX; 94/9/EG) available for 60 Hz power systems and other mains voltages Drive selection In the selection of the drive, effective weight is to be considered, particularly the weight of the user device to be screwed on securely. The weight of the material conveyed is itself negligible in the case of the synchronized AViTEQ small conveying drives. If the effective weight of th

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ parts conveyors for ordered arranging, individualizing and conveying are used in every case where mass parts have to be supplied to a magazine, a machine or to installation equipment, item for item, with a pre-determined orientation and time. Advantages and benefits High level of conveying capacity with compact dimensions operationally safe in continuous employment synchronized two-mass vibration system no influencing of the vibration characteristics through the weight of the parts being conveyed maintenance-free drive conformity with all EC Guideline which affect the drives also available for explosion-endangered spaces (Ex), as well as for 60 Hz power systems and other mains voltages Bowl and drive selection The normal shape of the bowls is cylindrical, in certain cases also cone or step-shaped. Such a bowl is selected if parts tend to become jammed between spiral paths located over one another. The selection of the pot diameter depends of the size of the parts to be conveye

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Hopper impact vibrators/bin activators errect bunker walls by periodic oscillations in shock and so the friction between the bulk and bunker wall (caking). They are just for knocking out of forms, for shaking of chutes and downpipes, for better emptying of containers and bulk materials from adhering to solve, for example in filters. The most common activators are unbalanced motors and magnetic vibrators. For special and heavy demands, there are impact vibrators available. Advantages & benefits magnetic impact vibrators excite the bunker walls with aligned linear oscillations. They have no "run out" and respond immediately after switching; the vibrational intensity can be adjusted at the control unit unbalanced motors have a rotating direction of force, they put the bunker wall in uniform, universally effective vibration large vibratory force at small dimensions robust and undemanding Construction In certain cases, a single drive can already act as an activator. If there i

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

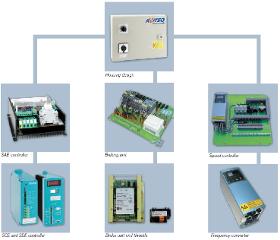

The AViTEQ Vobtronic units are fully equipped controllers for the operation of vibrators. About a variety of standard features and special designs the controllers can be used in many different industries and variable to adapt to the work environment. VIBTRONIC® -controllers are designed to supply AC voltage to control magnetic vibrators. They operate according to the principle of voltage control (phase-fired control). For all standard voltages in the 50 and 60 Hz main supply, AViTEQ has a suitable controller available in either a built-in or housing design. The controllers have voltage compensation for fluctuations in the main supply and some models have a limited control that rotects the magnetic vibrator from impact. The setpoint specification can be set using a potentiometer or an external setpoint (0-10 VDC or 0/4-20 mA). Information regarding operational status can be read from the integrated status relay and LEDs. Depending on the model, a vibrator current up to 100 A is possib

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ offers a wide range of accessories and spare parts for vibration plants and components. Pease contact us for solving your task. Contact us Download Liners - PDF (583kB) Download Sealings - PDF (438kB) Download Vibration insulation - PDF (706kB) Download AViTEQ Vibrationstechnik GmbH | Im Gotthelf 16 | 65795 Hattersheim | Germany Phone +49 (0)6145/503-0 | E-Mail info(at)aviteq.de © 2016 AViTEQ Vibrationstechnik GmbH

Request for a quoteManufacturer/ Producer

Im Gotthelf 16

65795 Hattersheim - Germany