- europages

- >

- Abrasive discs

- >

- FRIEDRICH AUGUST PICARD GMBH & CO. KG

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Manufacturer/ Producer

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We offer a wide variety of grades with various dimensions and grain sizes of abrasive belts that are perfectly suited to your application and processes. We will be happy to advise you to find the right sanding belts for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

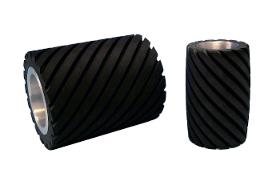

Rollers with a diameter of less than 75 mm are called contact rollers. They are equipped with a metal core flush on both sides and either covered with para rubber or Vulkollan®. The hardness of the coating is usually approx. 60º Shore, but other hardnesses are also possible. The coating of the contact rollers can, for example, be provided with grooves on request. Advantages Advantages of contact rollers FAPI-PA that have these coatings are: Wear resistance Oil resistance Fat resistance Emulsion resistance Ball bearings can also be easily integrated into the metal core from a roll width of 20 mm. Due to these outstanding flexible properties, Picard’s FAPI-PA contact rollers have proven themselves on the market for decades. Vulkollan® = registered trademark of the Covestro Group We will be happy to advise you in order to find a suitable contact role for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact disc FAPI-VU MILLED FREQUENCY DAMPED is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the contact disc’s foamed Vulkollan® covering. This reduces the noise level to a minimum during the belt grinding process and increases the removal rate to a maximum. The aggressiveness effect of the contact disk can also be optimized for each application using an individually optimized groove width-groove depth-web width ratio for milled, frequency-damped contact disks so that high-performance processes are possible. As with all contact discs in the VU series, there are no signs of fatigue after long, intensive use.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan® by its slightly yellowish color. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteAs a family-run company now in its fourth generation, we have been a leading manufacturer of grinding, deburring, polishing and brushing tools as well as contact discs and contact rollers for more than 110 years. We are also a recognised partners to companies across a wide variety of industrial sectors. Alongside our extremely wide range of (standard) products, we are primarily distinguished by our flexibility, which allows us to respond to our customers' requirements as quickly as possible. Alongside our own products, we can also supply you with abrasives affixed to supporting material (abrasive belts), grinding machines, polishing machines, hand-guided machinery, extraction systems, and plenty of other options. The quality of our manufacturing and retail products is our highest priority.

Website

Documents

Manufacturer/ Producer

Heinrich-Schicht-Strasse 7

42499 Hückeswagen - Germany

Company info

Key figures

-

- Company headcount

- 11 – 50

-

- Sales staff

- 1 – 10

Organisation

-

- Year established

- 1907

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of FRIEDRICH AUGUST PICARD GMBH & CO. KG

- Abrasive discs

- Deburring tools

- Deburring discs

- Deburring abrasive discs

- Deburring grinding rollers

- Deburring abrasive segments

- Contact discs

- contact pulleys

- Expander rollers

- Expander discs