FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Manufacturer/ Producer

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We offer a wide variety of grades with various dimensions and grain sizes of abrasive belts that are perfectly suited to your application and processes. We will be happy to advise you to find the right sanding belts for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Cleaning discs FAPI-CLEAN provide very good results when grinding and cleaning metal, stainless steel, wood or plastic and can therefore be used as a preliminary stage for grinding/polishing. We will be happy to advise you by telephone or at your site whether the use of cleaning discs FAPI-CLEAN also makes sense in your company for your processes. Construction Cleaning discs FAPI-CLEAN consist of knitted nylon threads which have been soaked in synthetic resin and gently cured. They are available on fabric plates and for use on straight and shaft grinders. Applications The cleaning discs are suitable for cleaning and polishing all surfaces. Scratch-free removal of paint, rust, scale and welding spots from metal Cleaning wood and plastic Remove paint from wood Free stainless steel from blue colouring Dimensions For cleaning discs FAPI-CLEAN the principle applies that they may only be used in conjunction with a clamping shank. Notice: For cleaning discs, the principle applies...

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

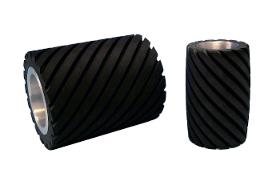

Rollers with a diameter of less than 75 mm are called contact rollers. They are equipped with a metal core flush on both sides and either covered with para rubber or Vulkollan®. The hardness of the coating is usually approx. 60º Shore, but other hardnesses are also possible. The coating of the contact rollers can, for example, be provided with grooves on request. Advantages Advantages of contact rollers FAPI-PA that have these coatings are: Wear resistance Oil resistance Fat resistance Emulsion resistance Ball bearings can also be easily integrated into the metal core from a roll width of 20 mm. Due to these outstanding flexible properties, Picard’s FAPI-PA contact rollers have proven themselves on the market for decades. Vulkollan® = registered trademark of the Covestro Group We will be happy to advise you in order to find a suitable contact role for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

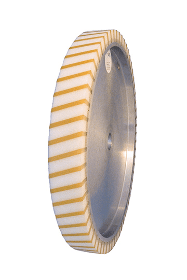

The contact disc FAPI-VU MILLED FREQUENCY DAMPED is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the contact disc’s foamed Vulkollan® covering. This reduces the noise level to a minimum during the belt grinding process and increases the removal rate to a maximum. The aggressiveness effect of the contact disk can also be optimized for each application using an individually optimized groove width-groove depth-web width ratio for milled, frequency-damped contact disks so that high-performance processes are possible. As with all contact discs in the VU series, there are no signs of fatigue after long, intensive use.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan® by its slightly yellowish color. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

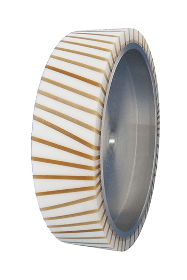

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Lamellae of foamed up Vulkollan® and plastic foam are attached alternately to the aluminium hub of the contact wheel FAPI-KS/V. While the width of the lamellae of foamed up Vulkollan® should be kept constant, the width of the plastic foam lamellae can be varied. The wider the plastic foam lamella is, the more aggressive the contact wheel will be. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The longer the lamellae are, the less rigid the material becomes, which in turn reduces the aggressiveness of the contact wheel. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide lamellae of foamed up Vulkollan® are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range generated during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-KS/V FREQUENCY DAMPED achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide lamellae of foamed up Vulkollan® are attached at alternating angles with plastic foam lamellae attached in the spaces between them to the aluminium hub of the FAPI-KS/V SPECIAL. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The longer the lamellae are, the less rigid the material becomes, which in turn reduces the aggressiveness of the contact wheel. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. Benefits of contact wheels with this design: Maximum removal rate Plastic lamellae provide optimum cooling of the abrasive belt Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PA MILLED is the addition to the smooth model. At this type grooves will be milled in the rubber coating.The grooves can be milled into the coating in various widths, depths and angles. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. Due to the milled grooves, the contact disks are much more aggressive than smooth contact disks. The aggressive effect of the contact disk can be optimized for each application through an optimal ratio of groove and web width so that high-performance processes are possible. This contact disc also impresses with its longevity.The contact disks of the FAPI-PA series are exclusively provided with an NBR coating. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates – the aluminium hub of the contact wheel FAPI-PA SMOOTH is coated with a smooth para rubber coating. While a coating height of 20 mm has established itself as the standard, the coating height is variable as desired. The smooth design of the contact wheel is suitable for the heaviest grinding and roughing. It is also attractive due to its long service life. Advantages The contact wheels of the FAPI-PA – series are coated only with para rubber. The para rubber (PA) coated contact wheels are in practice often simply called “rubber coated contact wheels” or rubber contact wheels. Benefits of contact wheels with this design: Highest service life Wear-resistance Oil-resistance Grease-resistance Emulsion-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteManufacturer/ Producer

Heinrich-Schicht-Strasse 7

42499 Hückeswagen - Germany