- europages

- >

- Fasteners- metal

- >

- HONSEL-GROUP

- >

- products

HONSEL-GROUP

Germany

Distributor

HONSEL-GROUP

Germany

CERTO® – The Leak-tight Thanks to their cup-shaped rivet sleeves, CERTO® sealing blind rivets are the specialists when it comes to liquid-tight riveting. Thanks to this special design, the breakstem is also captive. The rivet forms a smooth, burr-free blind head and is suitable for automatic riveting. Blind rivets are one of the most extensively used fasteners worldwide. An almost endless diversity of types, sizes and formats ensure solutions for all applications. For years, HONSEL has focused primarily on the manufacture of non-standard blind rivets.

Request for a quote

HONSEL-GROUP

Germany

The classic model. The designation ALFO® stands for the product range of HONSEL open standard blind rivets that are available with dome, countersunk or large dome head. It covers the versions and special types described in DIN EN ISO 15977 to 15984 as well as 16582 and 16584. “Special types” by our definition are rivets with a function as described in the above standards, but with differences in certain dimensions, functional properties or material combinations.

Request for a quote

HONSEL-GROUP

Germany

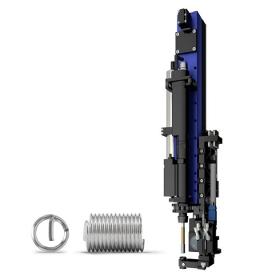

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

HONSEL-GROUP

Germany

The HONSEL RIVET NUT "headless" can be used in existing and new applications. The blind rivet nut can be flush mounted in smooth bores without countersinking. The omission of the "countersink" process of the hole realizes enormous potential for savings. Due to the 0 mm protrusion, components can be mounted without interfering edges or slide over one another without obstruction. Advantages: — Flush mount in smooth bores — No countersink required — Protrusion 0 mm — No interfering edges — High-quality corrosion protection (zinc-nickel) with 720 h salt spray test resistance

Request for a quote

HONSEL-GROUP

Germany

The HONSEL COIL "cone" can be installed in the same way as a coil with tab. No additional or special tools are required for process-reliable installation. When the HONSEL COIL "cone" is screwed onto the installation spindle, the conical portion of the wire thread insert creates a clamping effect between the installation tool and the coil. This ensures a stable installation process into the work piece. Advantages: — tab-free and therefore optimally designed for e-mobility due to no risk of tab debris. — Shallower blind hole depths can be realized — Subsequent processes are no longer necessary (breaking and removing of the installation tab) — No thread skipping during installation — Cycle time reduction of 20-30 % per installation — No special tools required for the installation process — The installation process improves due to the conical portion

Request for a quoteDistributor

Friedrich-Wöhler-Str. 44

24536 Neumünster - Germany