JET FLOW TECHNOLOGIES UK LIMITED - Ejector Vacuum System, Feedwater Heater, Steam Condensing, Steam Converting & Desuperheating systems

United Kingdom

Manufacturer/ Producer

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Vacuum is necessary during various steps of edible / vegetable oil and food processing. These steps essentially include hydrogenation, fractionation, bleaching, deodorization and deacidification. Out of all vacuum equipments, Ejector Vacuum System has established the superiority and versatility of their use as compared to mechanical vacuum pumps. The most outstanding advantage of the Steam Jet Ejector is total absence of moving parts which eliminate mechanical breakdown, and assures constant and dependable operation with freedom from repairs. No adjustment or lubrication is required nor are any specially trained operator necessary as their operation is very simple. Over and above, Steam Jet Ejector Vacuum System convey at very high velocity which are many times the speed of sound, they are capable f handling large volume under vacuum thus making them eminently suitable for deodorization application wherein high quality of open / sparging steam has to be handled.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Steam Conditioning Valve / Combined PRDS Valve is the combination of pressure reduction and temperature reduction of superheated steam to fit process needs, protect downstream equipment or allow the use of less expensive materials or schedules for downstream piping. This is done with a pressure reducing valve and a spray water addition section either as separate units or a single device. Pressure reduction is carried out with a pressure reducing trim within the valve body, usually multi stage pressure reduction. The pressure is controlled by an upstream or downstream pressure controller, signaling the valve to modulate to maintain the pressure at the required set point.Temperature is controlled by adding water to the steam in such away that it will get fully evaporated in the steam, termed as desuperheatmg. These applications are normally considered to be some of the most severe services of any valves in a modem steam plant.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The Steam Surface condenser is a critical component of both the traditional coal fired power plant and the new generation cogeneration and combined cycle power plants. Main duties of any Surface Condenser are to convert the exhaust steam from its gaseous to its liquid state at certain under atmospheric pressure, and also, to release non condensable presented in the steam cycle, together with vacuum unit. Jet Flow designs and economically sized condenser suitable for smaller turbine ratings under 100 MW. The circular configuration is compact for easy shipping and maintains the level of quality afforded all of our condenser designs. All of Jet Flow’s Surface Condensers are designed and built to the Heat Exchange Institute latest Standards. We also strive to meet all of our client’s project specific requirements.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow multi orifice desuperheater regulates the amount of injected water by varying the number of orifices during operation. The ensures that the spray water pressure remains constant at all loads and an excellent and almost uniform spray quality is achieved over the full operating range, thereby minimising the tendency of spray water to accumulate in the steam line. Opening of the orifices is regulated by the positioning of a piston operated actuator directly mounted on the desuperheater. This compact and simple design ensures no separate spray water Injection control valve is required.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Large industrial plants often vent significant quantities of low pressure steam to the atmosphere, wasting energy, water, and watertreatment chemicals. Recovery of the latent heat content of lowpressure steam reduces the boiler load, resulting in energy and fuel cost savings. Lowpressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level. Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle energy contained in high pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The needs of the power generation industry include year in and year out reliability, optimum performance for maximum efficiency, and absolute on time delivery to meet plant outage schedules. All of the Jet Flow Boiler Feed Water Heaters are designed in accordance with HEI standards, TEMA and ASME codes. Jet Flow uses state of the art computer programs to perform the thermal hydraulic and mechanical design of each Feed Water Heater we fabricate. Jet Flow designs and manufactures both Low Pressure (LP) and High Pressure (HP) feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements. Each Jet Flow Feed Water Heater will contain from one to three separate heat transfer areas of zones including the Condensing, Desuperheating and Subcooling zones. Our heaters can be provided with multiple zones within the shell side Condensing Zone Included in all heaters,steam is condensed in this zone and non condensable gases are removed.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

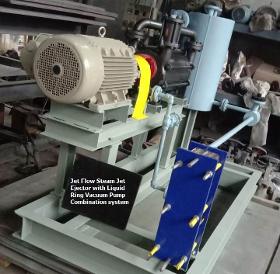

Jet Flow Steam Jet Ejector and Liquid Ring Pump Combination type Hybrid Ejectors Systems are getting popular in major Chemical, Soap, Food, Edible oil sectors. A typical combination of steam jet ejector system followed by inter-condenser and liquid ring vacuum pump. This type of combination system can achieve vacuum as high as 0.05 Torr. It can be configured as single or multistage ejectors, single or two stage liquid ring vacuum pumps and inter-condenser. It is designed to operate at the same capacities and suction pressures as conventional steam jet ejector systems. Jet Flow Hybrid Ejectors provide a solution for high vacuum operations. They are versatile in handling both wet and dry loads, can be supplied with low level skid mounted packages with instrumentation and with closed loop seal water recycle system for vacuum pumps for the total reduction of effluent. Jet Flow combination type vacuum systems major applications in distillation, evacuation, drying, evaporation, cooling etc.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

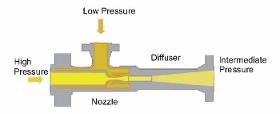

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Request for a quoteManufacturer/ Producer

Kemp House

160 city road

EX1V 2NX London - United Kingdom