- europages

- >

- Drawing - steel and metals

- >

- JONAS WERKZEUGBAU STANZEREI GMBH

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Manufacturer/ Producer

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

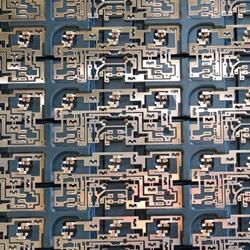

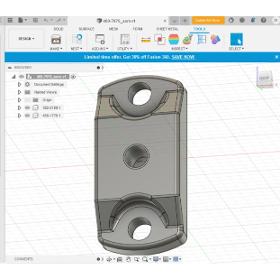

For more than 25 years our name has stood for experience, professional competence and consumer-orientated service. Moreover, our clients hold the opinion that our skills in producing multi-part press tools and fixture constructions are absolutely convincing. These tools are implied for instance within the framework of electronic and automotive industry in favour of processing different materials. Thus, your needs will be developed gradually. By using up-to-date software we produce high standard multi-part press tools for national and international clients. With the professional help of the CAD/CAM-Software (Cimatron) we generate 3D-construcions and solids. For data migration we offer several interfaces: Step – DWG – IGES – DXF – just choose what you need. Immediate interfaces that lead directly from the CAD-workstation to the machine ensure shortest processing times.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

We accept responsibility for the whole process of production. On the one hand, we set outsourced items or provided parts like Press-in bolts Clinch studs Ball studs Weld screws Weld nuts into complex assembly groups. On the other hand, we offer downstream services like Thread cutting Slide grinding Defatting Special packing operations (in trays / blister packaging, wound on spool, packed in layers) Your needs and wishes always have priority and always will have. For that purpose we cooperate with reliable suppliers, who take charge of downstream surface treatment like: Galvanising Chrome-plating KTL-coating Silver-plating Hardening Press tempering Powder coating On your wish we guarantee particle purity and silicone-free packing.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

– up-to-date methods for ideal results We manufacture every part variably and precisely using up-to-date techniques. Our objective: to put your requirements in the nutshell. With our modern die-cutting systems we satisfy your needs and produce i.a. Precision stamping parts Bending parts Drawing parts Contacts Complex lead frames Our automatic cutting presses and eccentric presses dispose a press capacity from 250 kN to 2800 kN. With the assistance of our actual manufacturing site we nearly handle every kind of requested material. For instance: Copper Cu Bronze CuSn Brass CuZn Steel DD, DC Coated strip material Chrome-nickel-steel X10CrNi / 1.4310 with a stability from 600 to 2.200 N/mm² Stainless steel X5CrNi / 1.4301 Aluminium AL The material can be already galvanised, tin-plated, silver-plated or gold-plated. Just tell us what you need. We come along with the solution.

Request for a quoteAre you looking for an international and modern company with core expertise in stamping technology and tool manufacturing so that you can get everything from a single source? Then you have come to the right place. According to the individual needs of our customers, we manufacture progressive tools as well as drawing die and bending tools for the manufacture of various bending and stamping parts at our own tool manufacturing plant. Design, stamping and bending parts, parts cleaning and construction of tools – on time, with precision and at competitive prices for all customers and industries in equal measure. Our aim is to fulfil your requests and, where possible, to exceed your expectations. Our services: Construction: 3D constructions of progressive tools using state-of-the-art software, tool manufacturing, stamping and bending parts, parts cleaning: Optimum cleaning results and residue-free drying guarantee component cleanliness in accordance with the highest standards.

Website

Documents

Manufacturer/ Producer

Otto-Diehls-Strasse 11

48291 Telgte - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

Organisation

-

- Year established

- 1990

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- National

Activities of JONAS WERKZEUGBAU STANZEREI GMBH

- Drawing - steel and metals

- aluminium punched parts

- Precision stamping parts

- tool manufacturing

- Part cleaning

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ANTHERMO GMBH

Germany

Special parts In addition to our standard delivery program, we can also procure and deliver special / drawing parts for special applications. This applies to welding outlets, fittings as well as eyeglass blinds and drawing parts. Special know-how Together with our long-term partner companies, we have the necessary know-how to also manufacture unusual drawing parts.

Request for a quote

METAL-TECH

Poland

DESIGNING DETAILS FOR THE CUSTOMER'S NEEDS

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Deep Drawn Parts – Quality Dee Drawing Service Ming Xiao Manufacturing Co., Ltd specialize in custom deep drawn parts more than 10 years, it’s made by hydraulic pressure machines or punch machine. material can be stainless steel 201, 304,316 and stainless iron, carbon steel, copper, Aluminum, etc. finish can be polishing, plating, powder coating, painting, etc. Deep drawing is the punch will move onto the flat sheet metal into the mold cavity in the cold forming process. Different from other drawing process, drawing a deep degree can pull more than its original diameter billet. Deep drawing technology in the production process is widely used. Drawing used in many industries. For example, you can use in the automotive industry in the production of automotive parts; also be used to manufacture household products, such as stainless steel kitchen sink,enclosure,console box or cover,motor shell… Welcome contact with us discuss your sheet metal deep drawn parts.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our work starts with precise and efficient material cutting using modern machines. Our Laser and plasma cutters are available for sheet metal processing of all grades. Laser Trumpf 4kW with interchangeable table 4000x2000mm cuts mild steel of max. 18mm with both oxygen or nitrogen. Plasma Omnicut/Hypertherm where portal is also fitted with an acetylene burner; table size 6500 x 2000mm, usually cuts max. thickness 100mm

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free